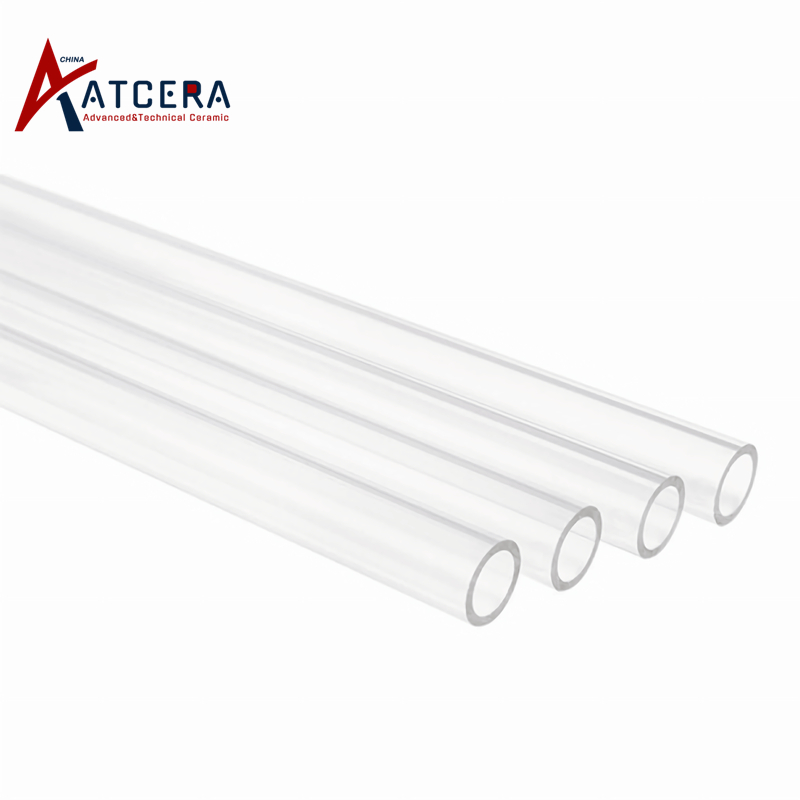

Standard Quartz Tubes

Semiconductor Manufacturing: Used in high-temperature furnaces and reactors, ensuring high purity and thermal stability.

Laser Technology: Provides excellent optical performance and high-temperature resistance.

Chemical Processing: Widely used in chemical reactors and distillation systems.

Capillary Quartz Tubes

Photoelectric Equipment: Used in photomultiplier tubes and light sensors.

Optical Communication: Efficiently transmits light signals.

Laboratory Instruments: Used in gas chromatography and sample handling.

Spiral Quartz Tubes

Chemical Processing: Used in chemical reactors and heat exchangers.

Food Manufacturing: Applied in pasteurization and sterilization processes. Environmental Testing: Used in water treatment systems.

UV Quartz Tubes

Germicidal Lamps: Used for air and water disinfection in medical and industrial environments.

Water Purification: Applied in UV water treatment systems.

Medical Equipment: Used for sterilization and air purification.

Double-Walled Quartz Tubes

Chemical Processing and Biopharmaceuticals: Used in reactors and incubators for precise temperature control.

High-Temperature Industrial Applications: Applied in industrial furnaces and high-temperature equipment.