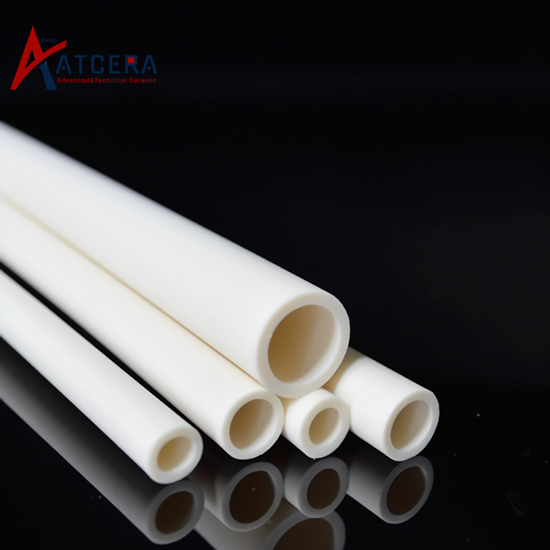

In the ever-evolving landscape of industrial materials, alumina ceramic tubes have emerged as a pivotal component, revolutionizing various industries with their unique properties. As the demand for high-performance materials continues to grow, alumina ceramic tubes, owing to their exceptional thermal conductivity, electrical insulation, and corrosion resistance, have become indispensable in numerous applications.

Characteristics of Alumina Ceramic Tubes

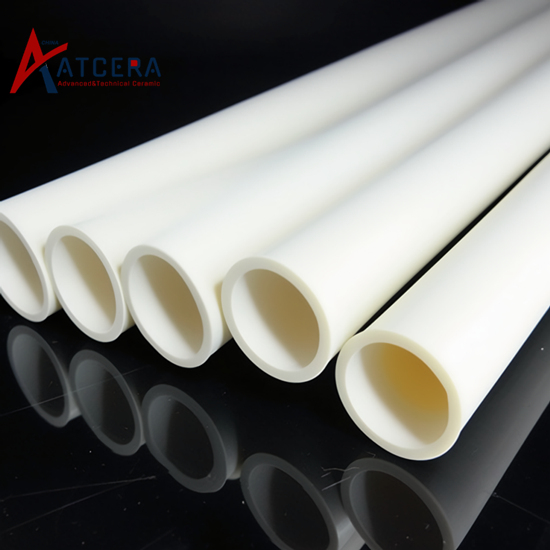

Alumina tubes are crafted from high-purity aluminum oxide powder, which is sintered into a dense and durable structure. Their unique material properties make them stand out in the market. These tubes exhibit excellent electrical insulation, with high breakdown voltages, ensuring safety in electrical and electronic applications. Furthermore, their superior mechanical strength and resistance to pressure and impact make them ideal for demanding environments. Alumina ceramic tubes are also noted for their high hardness, wear resistance, and long service life, while their ability to withstand high temperatures and thermal shock makes them invaluable in high-temperature applications.

Application Fields of Alumina Ceramic Tubes

The versatility of Al2O3 tubes is unparalleled. They are widely used in electrical and electronic equipment, serving as bases for electronic devices, wire sleeves, and other insulating parts. In mechanical engineering, alumina tubes are employed as high-temperature refractory pipes, powder conveying pipes, and chemical conveying pipes. Their thermal conductivity and heat shock resistance make them suitable for heat exchange pipes and thermocouple sleeves. Additionally, alumina ceramic tubes find applications in medical equipment and biology, owing to their non-toxic, harmless nature and good biological inert characteristics.

How to Select the Right Alumina Ceramic Tube for Your Project

Choosing the appropriate alumina ceramic tube for a specific project is crucial. Considerations such as the operating temperature, chemical environment, and mechanical stress must be taken into account. Understanding the material's properties and limitations is essential to ensure its suitability for the intended application. Consulting with experts or manufacturers can provide valuable insights into selecting the optimal alumina ceramic tube for your project.

Manufacturing Process of Alumina Ceramic Tubes

The manufacturing process of alumina ceramic tubes is a precise and meticulous one. Starting with high-purity aluminum oxide powder, the material is sintered at high temperatures to form a dense and durable ceramic structure. Precision machining techniques are then employed to shape and finalize the tubes, ensuring their dimensional accuracy and surface finish. The resulting alumina ceramic tubes are rigorously tested to ensure they meet stringent quality standards.

Case Studies and Success Stories of Using Alumina Ceramic Tubes

Numerous case studies and success stories demonstrate the value of alumina ceramic tubes in various applications. From enhancing the performance of electrical equipment to improving the efficiency of chemical processing, alumina ceramic tubes have proven their worth in numerous industries. Their ability to withstand harsh environments and maintain excellent performance has earned them widespread recognition and adoption.

Conclusion

As industrial applications continue to become more demanding, alumina ceramic tubes offer a reliable and efficient solution. Their unique properties, such as excellent thermal conductivity, electrical insulation, and corrosion resistance, make them invaluable in numerous industries. By understanding their characteristics and applications, selecting the right alumina ceramic tube for your project, and understanding their manufacturing process, you can unlock their full potential and enjoy the benefits they bring to your operations.