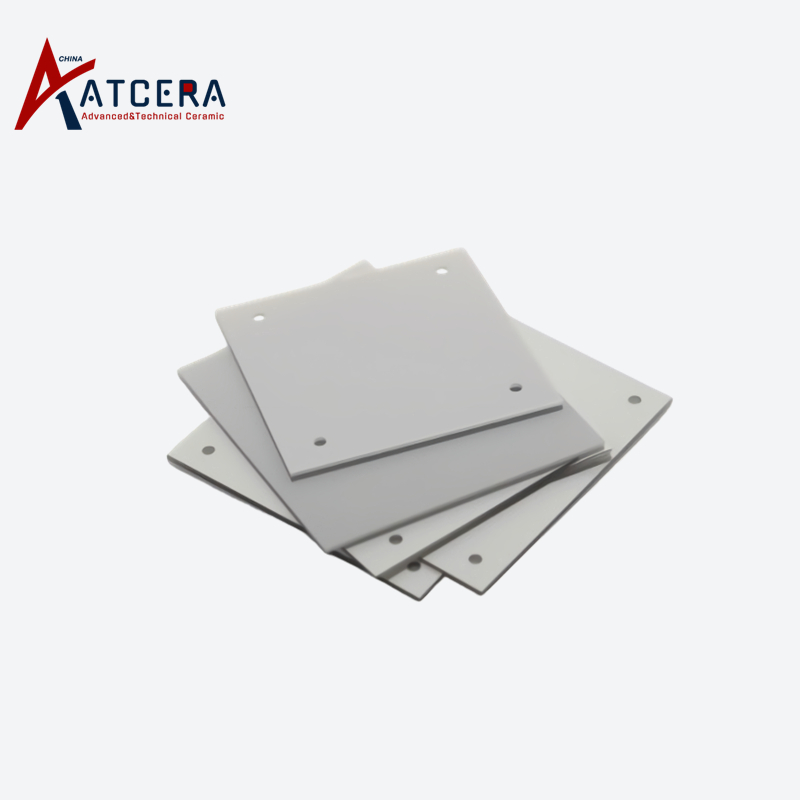

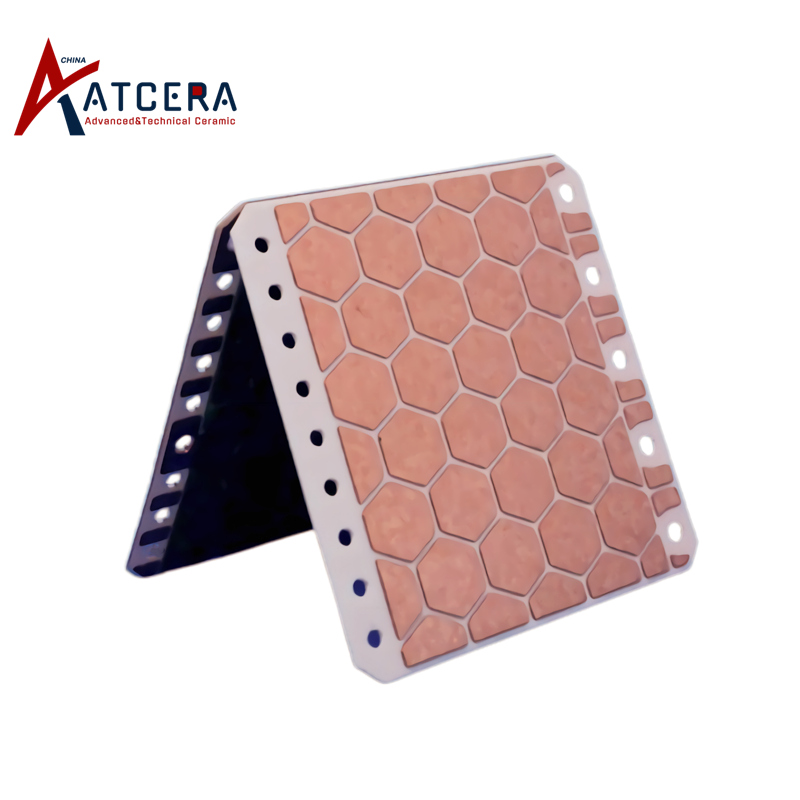

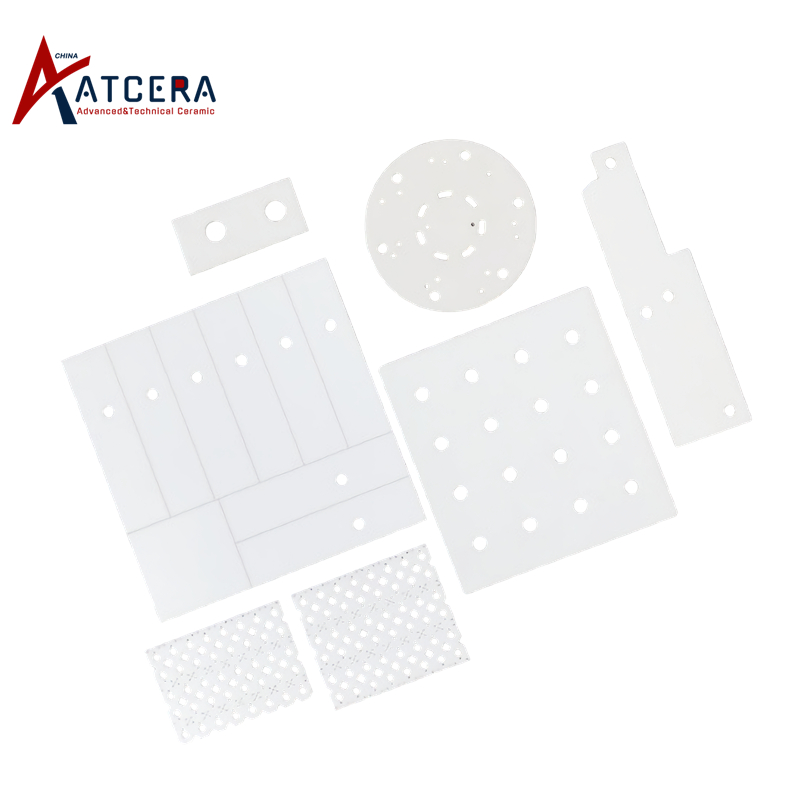

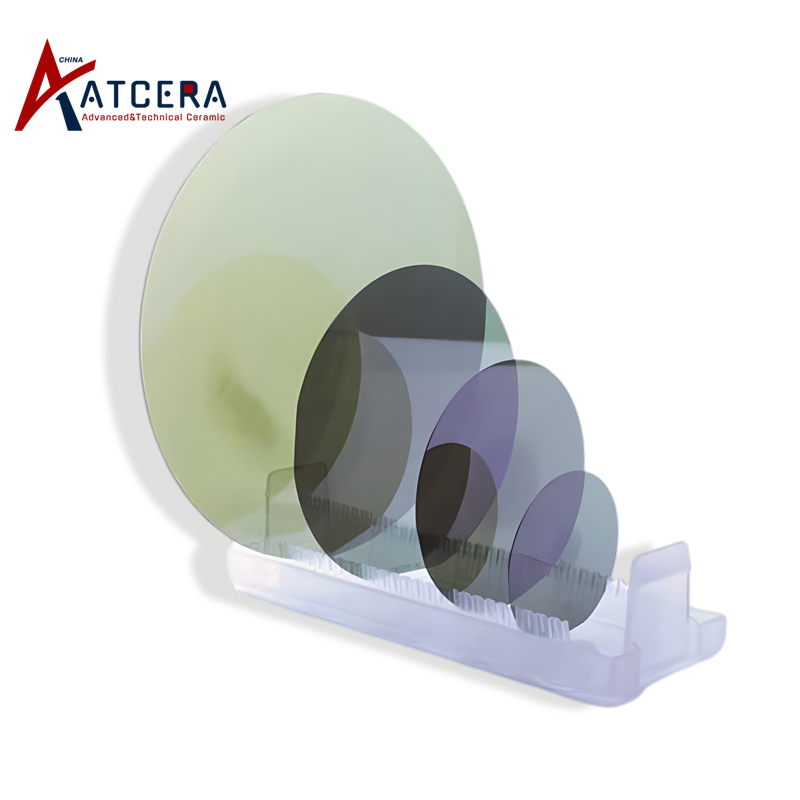

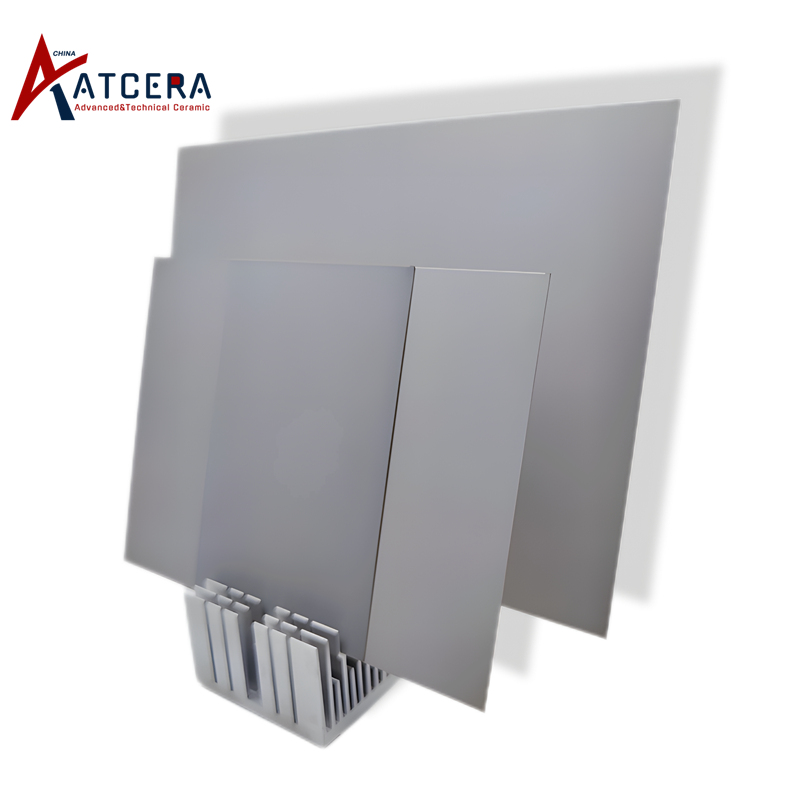

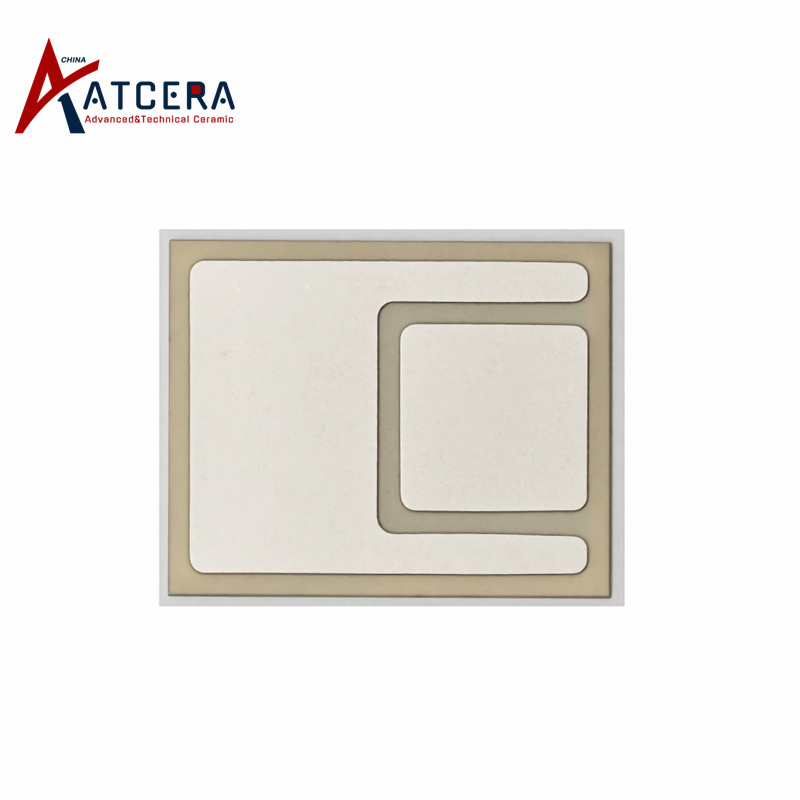

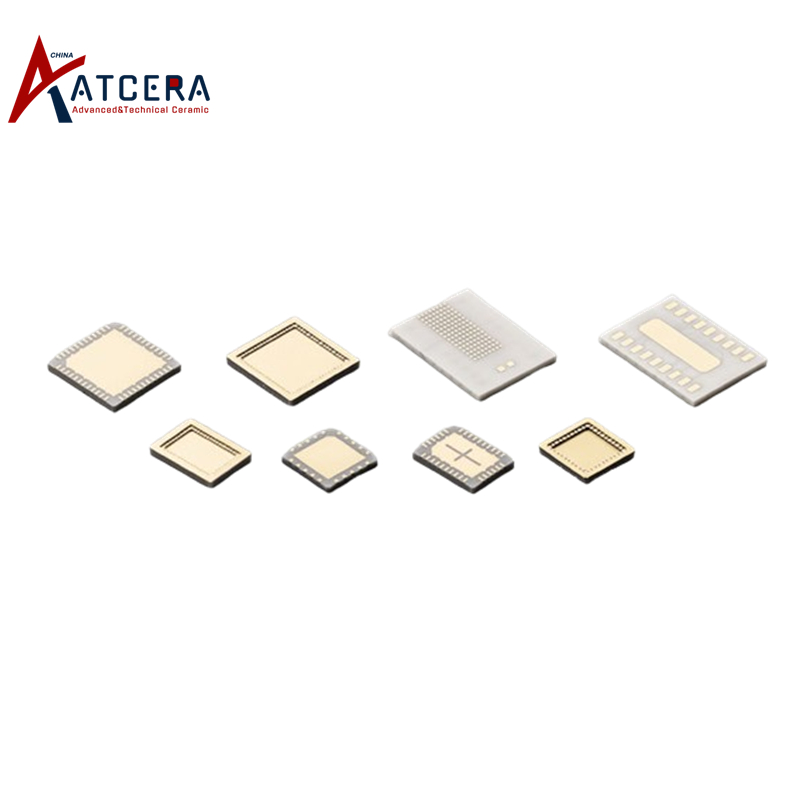

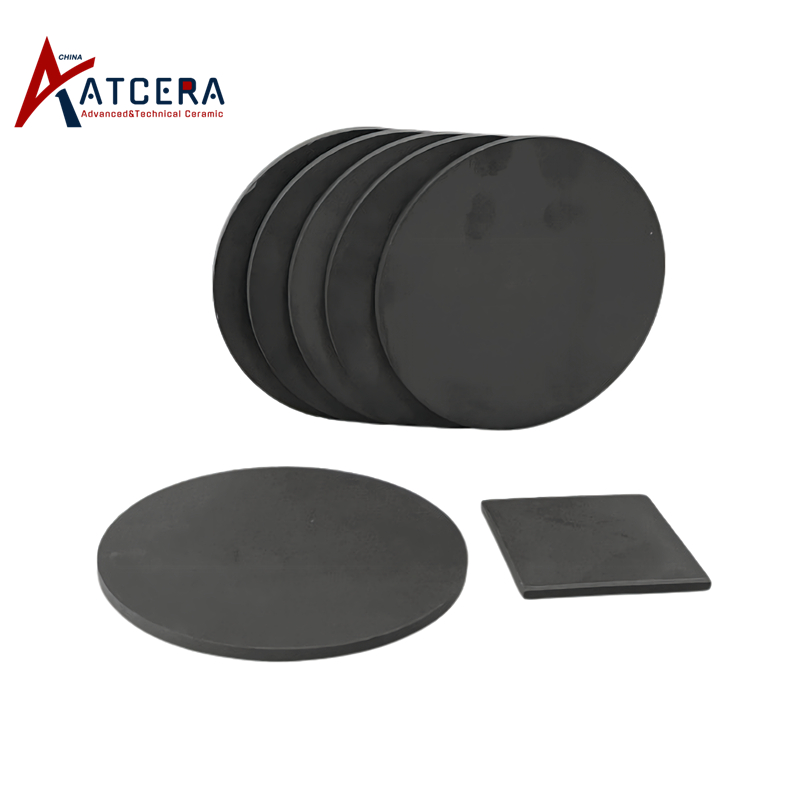

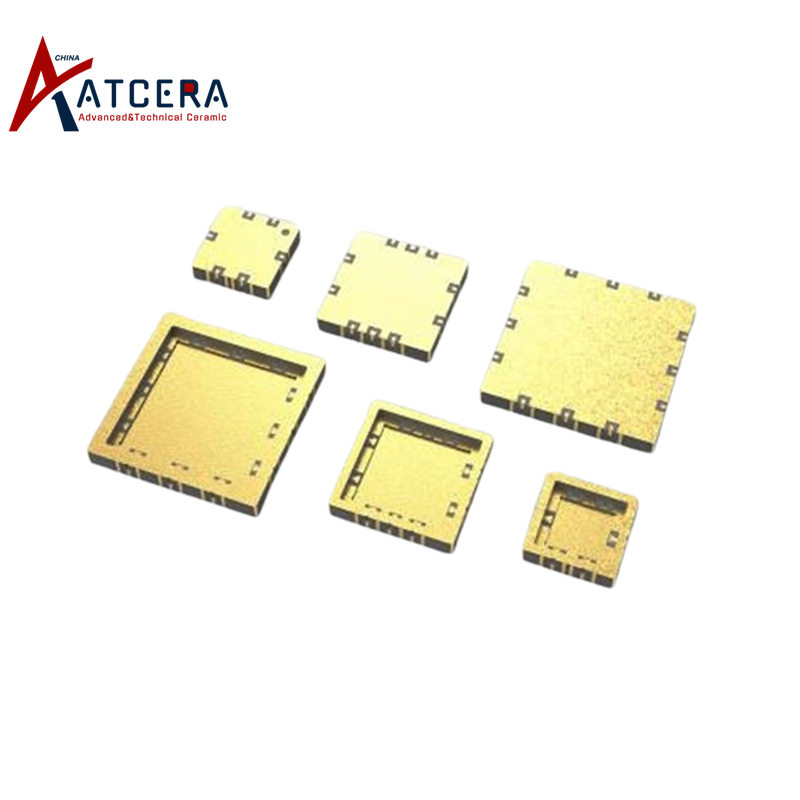

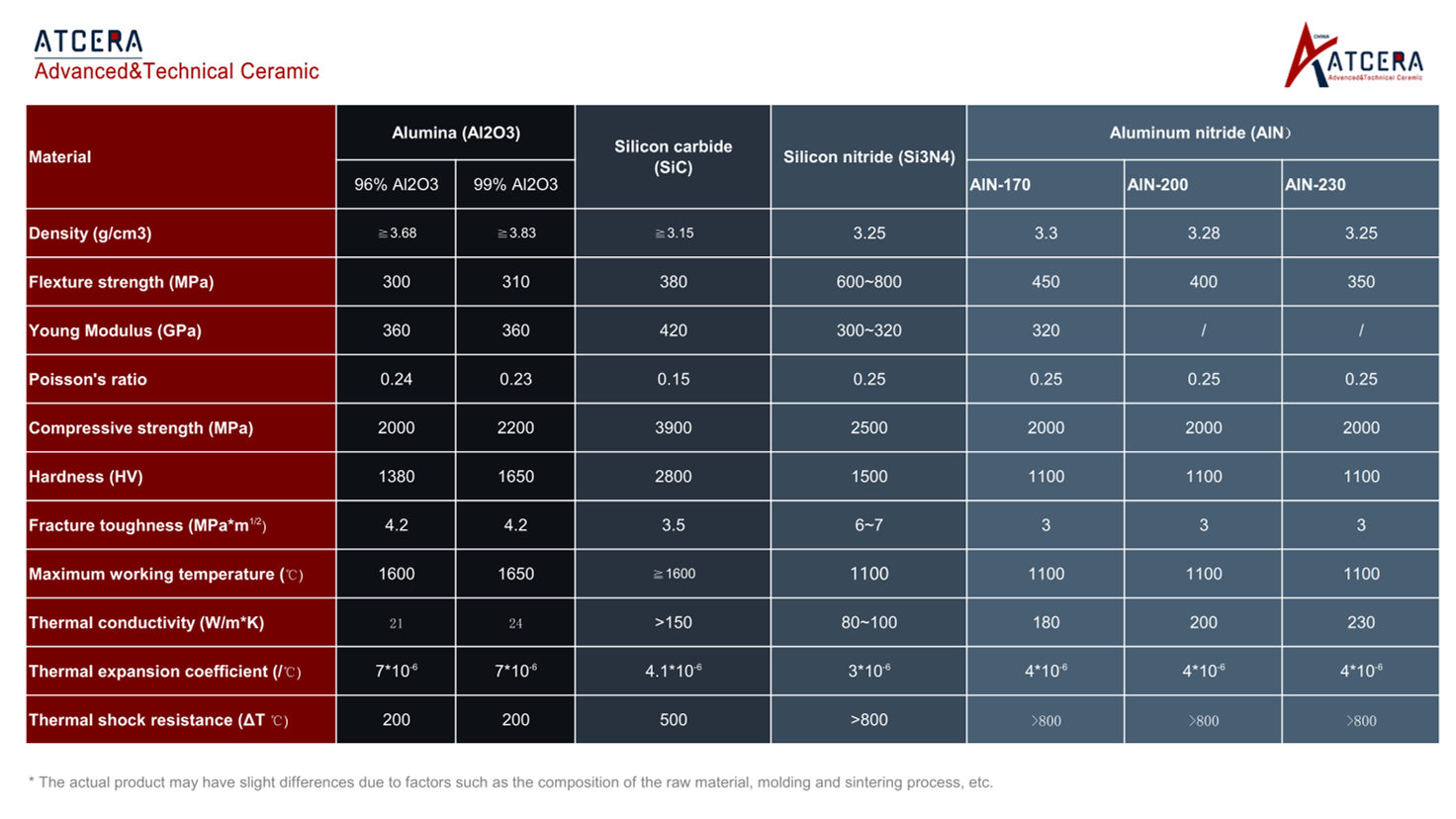

ATCERA can provide various materials of ceramic substrates, including alumina, silicon nitride, aluminum nitride and silicon nitride, they can be used to produce high performance integrated circuit (IC) and electronic components, like LED, power modules, frequency (RF) devices, piezoelectric components, photoelectric components, MEMS, etc., are widely applied in semiconductor, 5G and wireless communication, electric automobile, photovoltaic and wind power generation, data center and other industries.

| view all substrates |