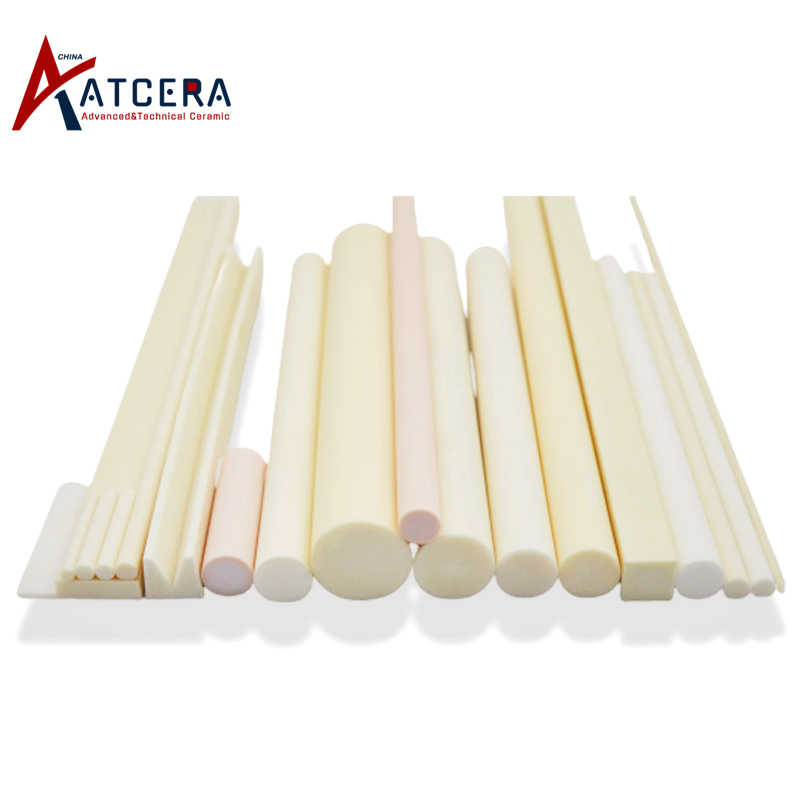

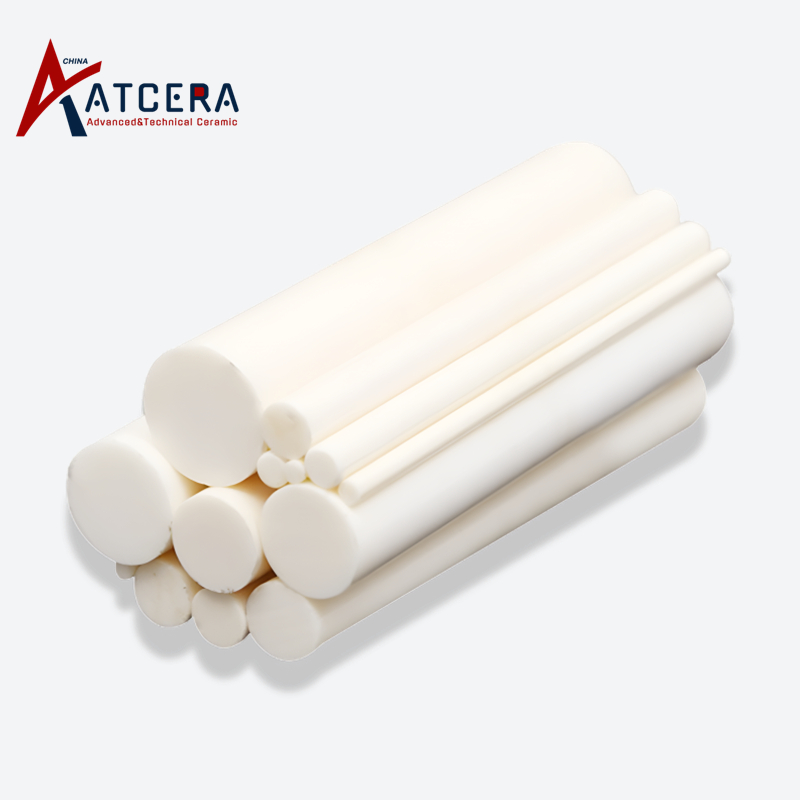

Alumina ceramic can be used to fabricate high temperature furnace roller rod, furnace lead-in rod, heat treatment furnace roller, heating rod, hydraulic rod, shaft, plunger, grinding rod and other wear parts, electrical insulation parts, chemical equipment parts, etc.

1. High temperature refractory industry

Alumina ceramic rod has high temperature resistance, good thermal shock resistance, oxidation resistance and good wear resistance, can maintain stable performance under harsh working conditions, in the high temperature refractory industry applications are mainly used as furnace roller rod, furnace inlet rod, heat treatment furnace roller, heating rod, etc.

2. Mechanical engineering industry

Alumina ceramic rod high compressive strength, good wear resistance, light weight, stable performance at high temperature, can be made into a variety of mechanical parts, including hydraulic rod, shaft, plunger, grinding rod, etc. Mechanical parts made by ceramic has longer service life than metal , meanwhile the weight of the parts can be greatly reduced.

3. Chemical and Metallurgical industries

Alumina ceramic rod has very good corrosion resistance, good chemical inertia, and does not react with various chemical media, suitable for manufacturing a variety of chemical equipment, such as stirring, support, drainage parts, etc., but also can be used as a variety of catalyst carrier, used in the chemical process.

4. Electronic and Electrical industry

Alumina ceramic rod has excellent electrical insulation performance, high breakdown resistance voltage, high mechanical strength, it can be used to produce electronic and electrical equipment insulation parts, which with high reliability and long service life.