1. Mechanical engineering industry

Alumina, zirconia, silicon carbide rods have high hardness, good wear resistance, also with good mechanical properties, they can stable performance at high temperature, can be made into various mechanical parts, such as connecting rod, transmission shaft, plunger, grinding rod, etc.

2. High temperature refractory industry

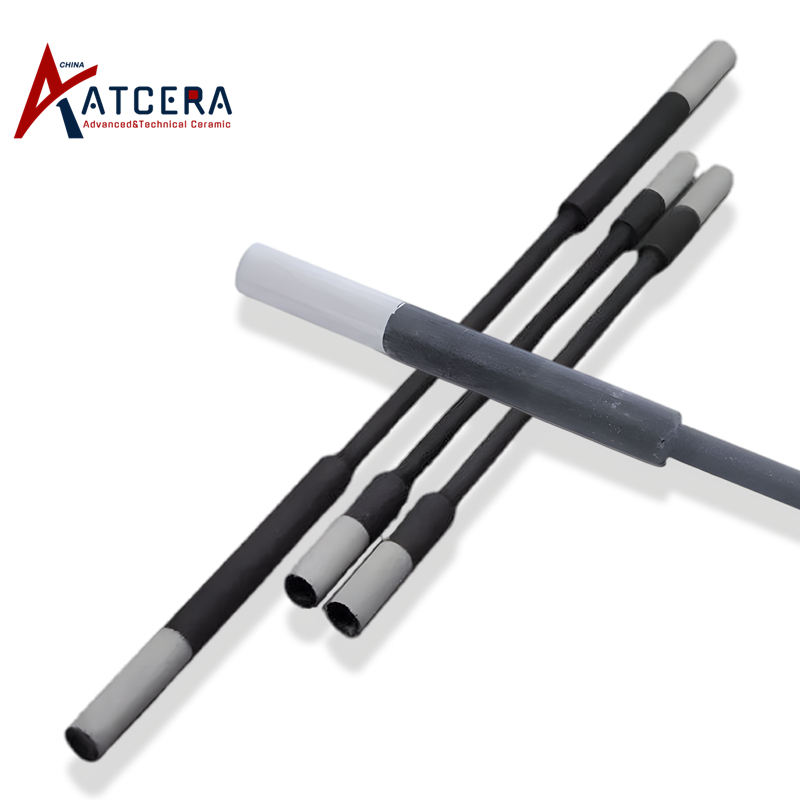

Alumina rods and ZTA rods have high temperature resistant, oxidation resistant, can maintain stable performance under harsh working conditions, and can be used to manufacture furnace roller rod, furnace inlet rod, heat treatment furnace roller, heating rod, etc.

3. Chemical and metallurgical industries

Alumina, zirconia and ZTA rods have very good corrosion resistance, good chemical inertia, and do not react with various chemical media, they are suitable for manufacturing a variety of chemical equipment, such as stirring, support, drainage parts, etc.

4. Optical components

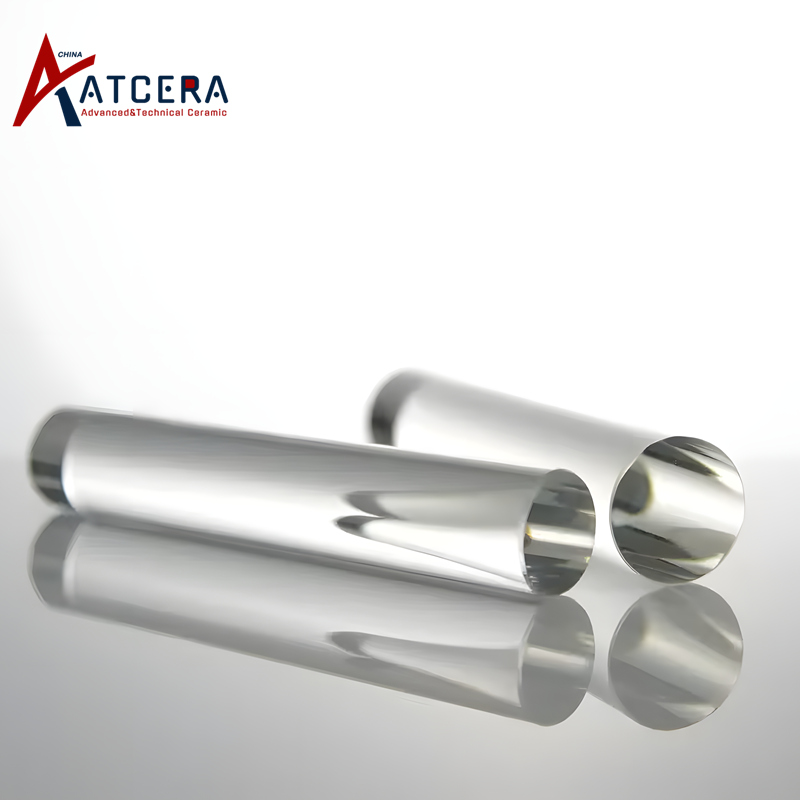

Quartz rod has good light transmittance, stable optical performance, high temperature and corrosion resistance, and can be used to manufacture a variety of optical and chemical experimental instruments.