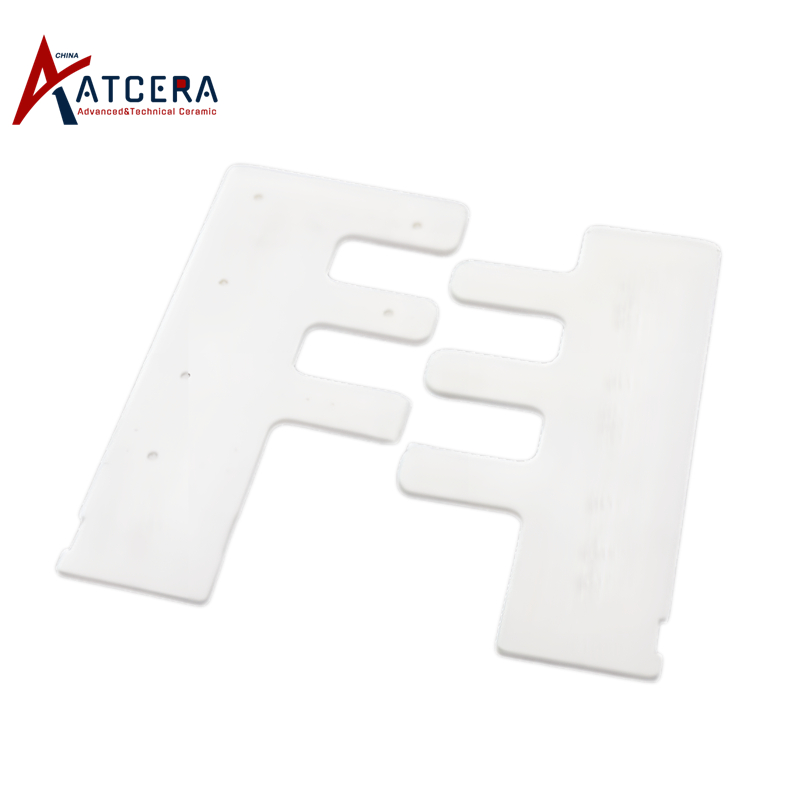

1. Ceramic substrate

Silicon carbide has has a wide energy gap, high thermal stability, and good thermal conductivity, it can be used to produce substrate for photovoltaic cell.

2. Ceramic wafer tray

Alumina and silicon carbide ceramics have high temperature resistance, and wear resistance, they can be used to produce tray to carry wafer for various process, such as RTA(Rapid Thermal Annealing), PVD(Physical vapor Deposition), ICP(Inductively Coupled Plasma), CMP(chemical mechanical polish), to get good processing effect and high efficiency;

3. Ceramic vacuum chuck

Alumina and silicon carbide ceramics have good finish surface, with strong absorption force when pumping air is applied, also ceramic vacuum chuck have high temperature resistance, and widely used to absorb and transfer wafer during the production process;

4. Wafer boat and boat bracket

Silicon carbide and quartz have high temperature resistance and good wear resistance, also the density is low and weight is light, they are suitable to produce wafer boat and boat bracket, to carry wafer for diffusion and oxidation treatment in a diffusion furnace.

5. Diffusion furnace tube

Quartz tube has high temperature resistance and excellent thermal stability, it can be used as diffusion furnace tube, for diffusion and oxidation process of solar cell silicon wafer.