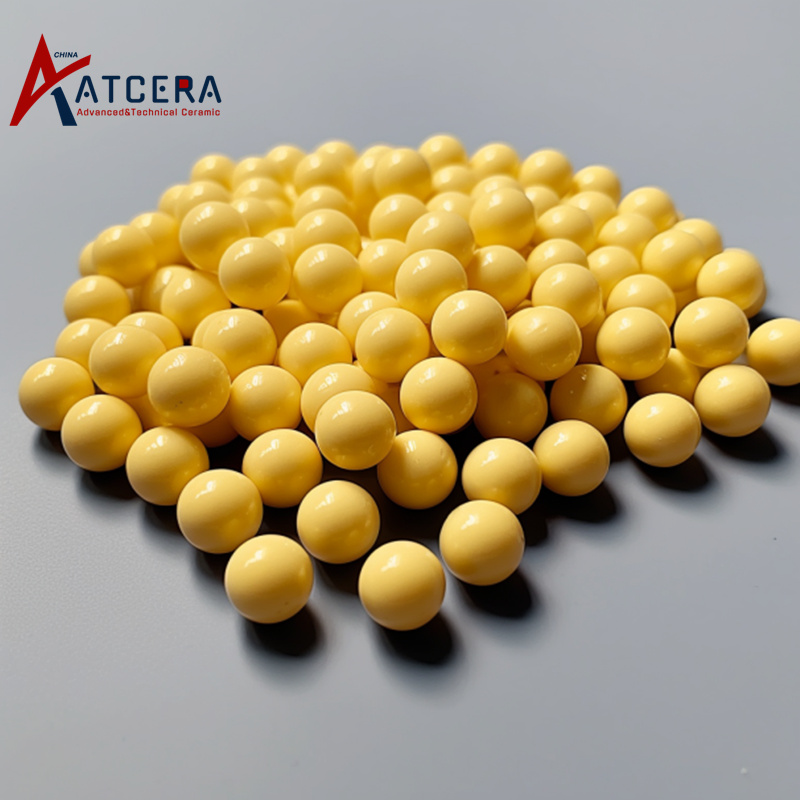

Zirconia bead, that is, high wear-resistant zirconia grinding ball, has high strength, high hardness, minimal wear, high fracture toughness, good wear resistance, high temperature resistance, corrosion resistance, no magnetic conductivity and electrical insulation characteristics, mainly used for ultra-fine grinding and dispersion of high hardness abrasive material.

| view all zirconia balls |