1. Chemical industry

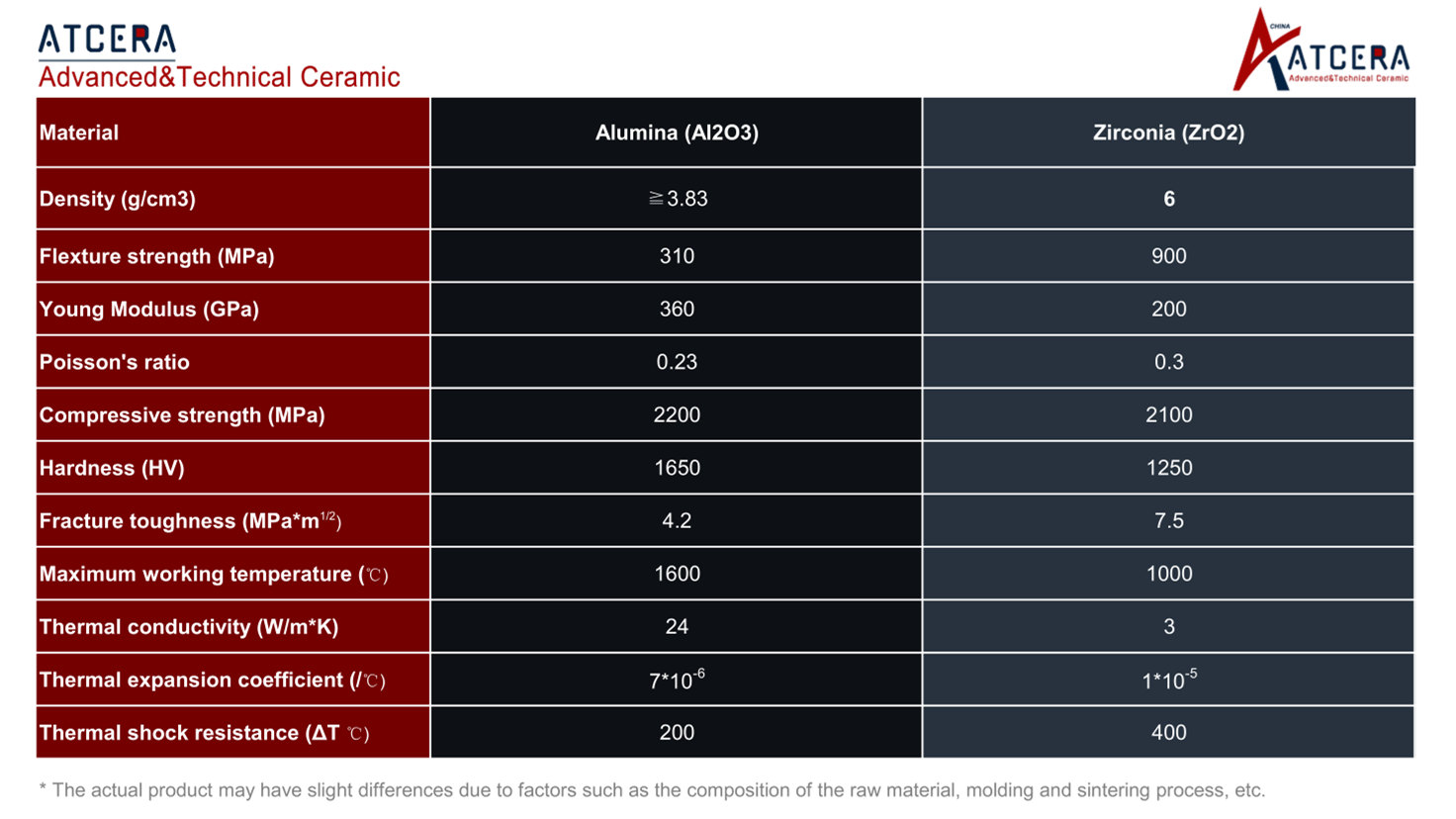

Alumina and zirconia ceramic pumps are chemically inert and have good corrosion resistance, they can be used for precision filling and metering of various chemical liquids, also for delivery and control the flow, such as chemical agents, battery electrolytes, etc.

2. Petroleum industry

Alumina and zirconia ceramic pumps can be used to delivery and metering lubricating oil, distillate oil and other processing raw materials, to ensure the accuracy and stability of oil processing and production.

3. Food manufacture

Alumina and zirconia ceramic pumps can be used to quantitative filling beverage, dairy products, spices and other liquids, filling accuracy is high, meanwhile without any influence to the quality and taste, also can be used to control the amount of food additives to be added.

4. Water treatment

Alumina and zirconia ceramic pumps can be used for water treatment and chemical agent dosing, to remove water scale, maintain water quality, and inhibit bacteria and algae growth.

5. Pharmaceutical industry

Alumina and zirconia ceramic pumps biocompatibility is good, they can be used for the filling and measurement of various liquid pharmaceutical and biological agents, to meet the high requirements for drug safety and stability in biomedicine field.

6. Cosmetics industry

Alumina and zirconia ceramic pumps can be used for perfume, lotion and other liquid cosmetics filling, with high precision and high efficiency, and no risk of contamination to the cosmetics.