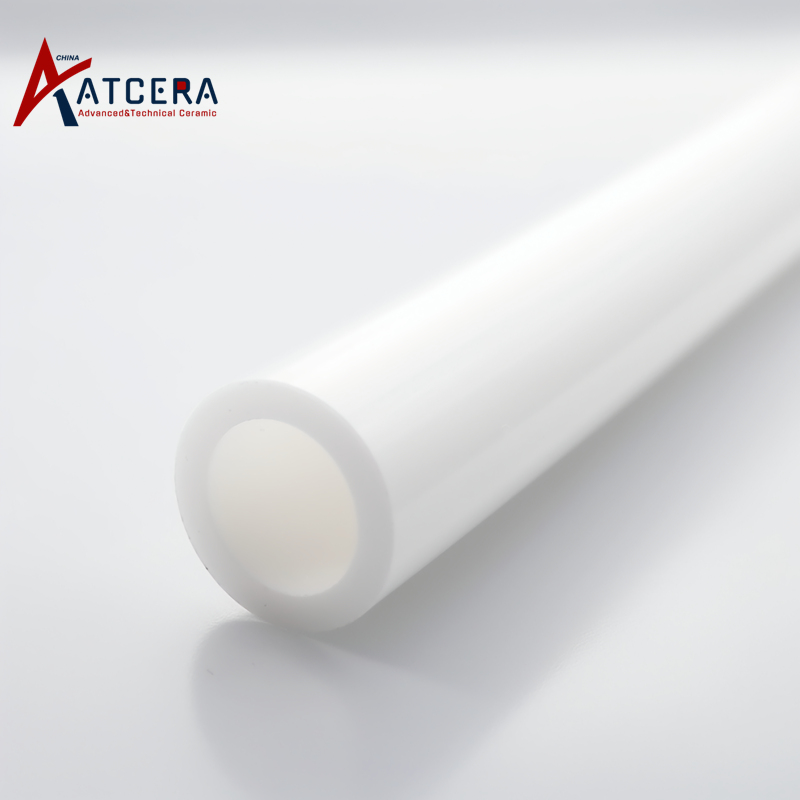

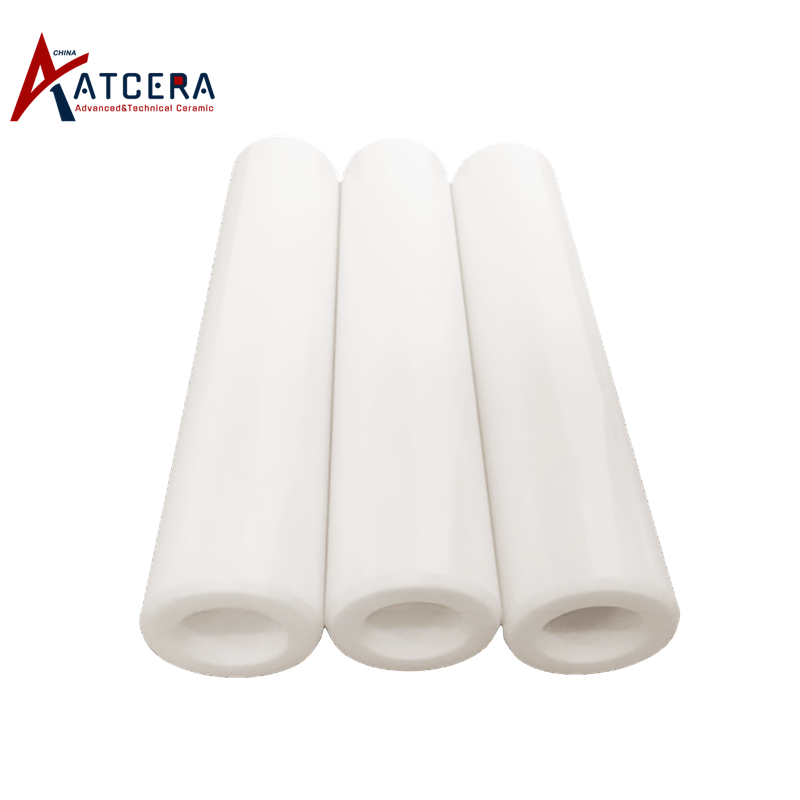

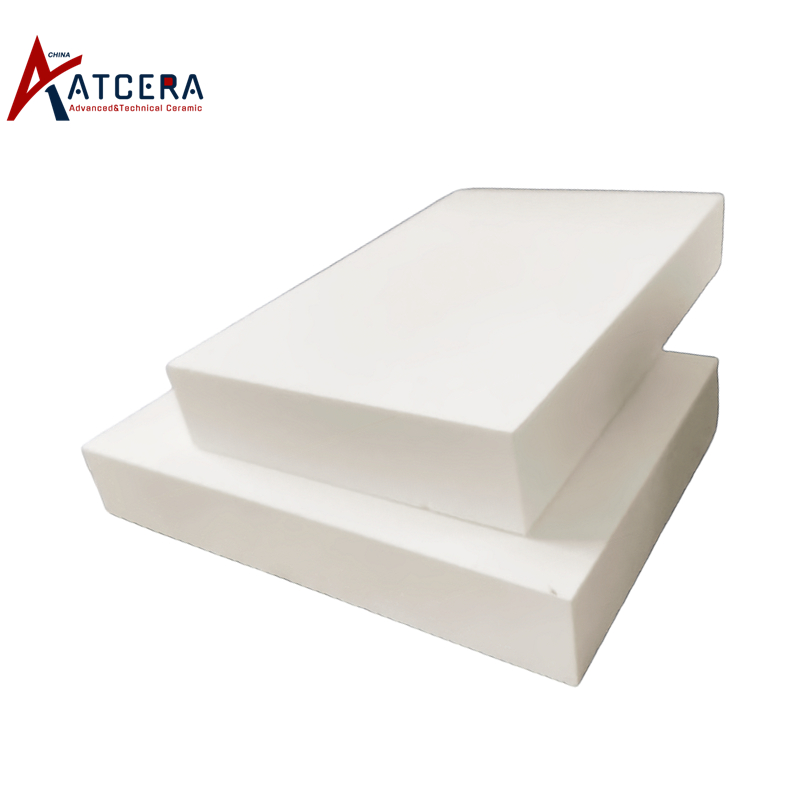

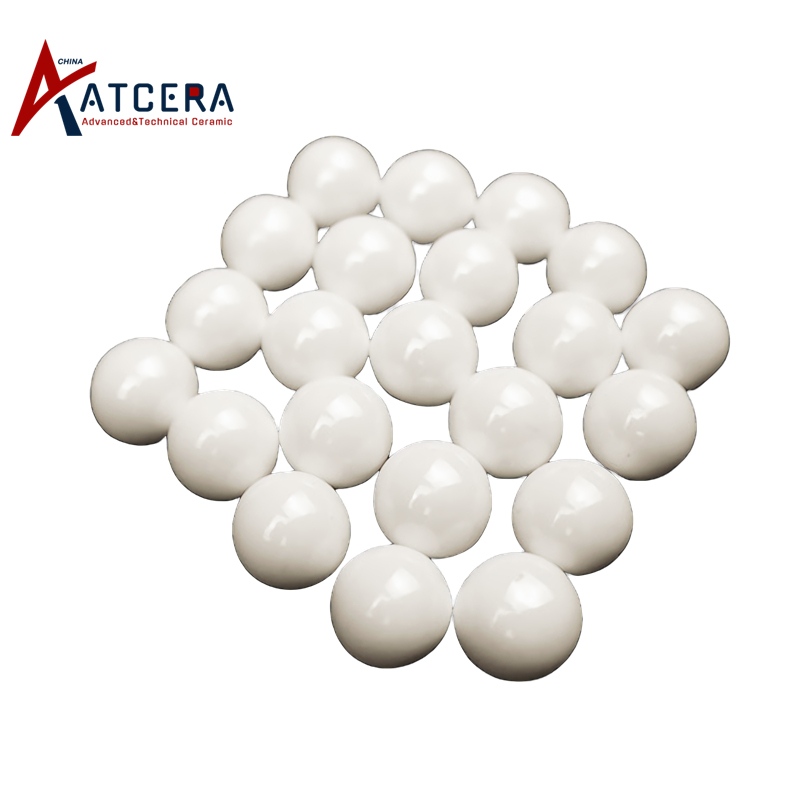

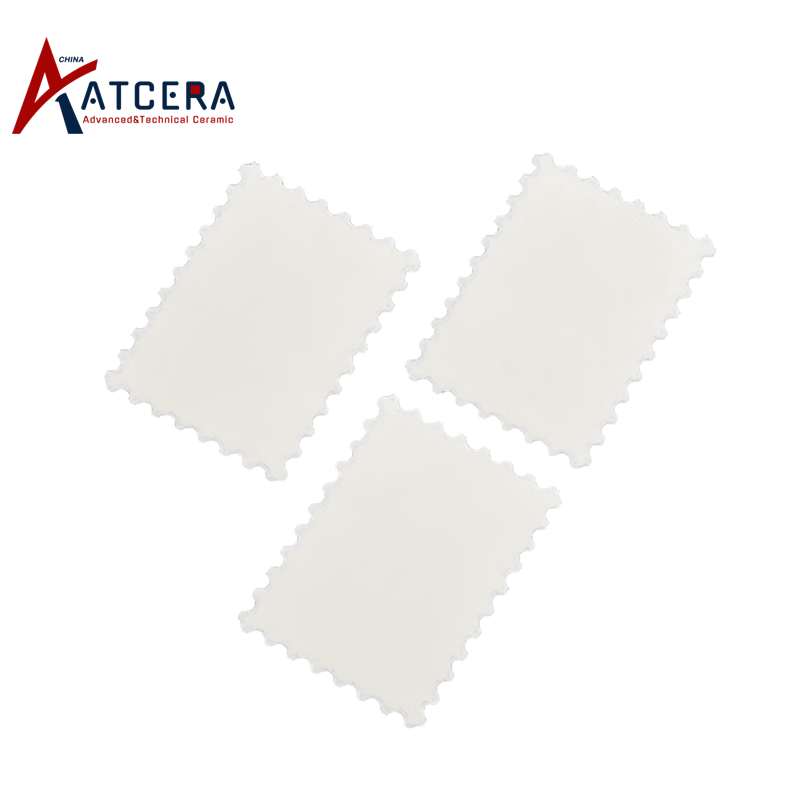

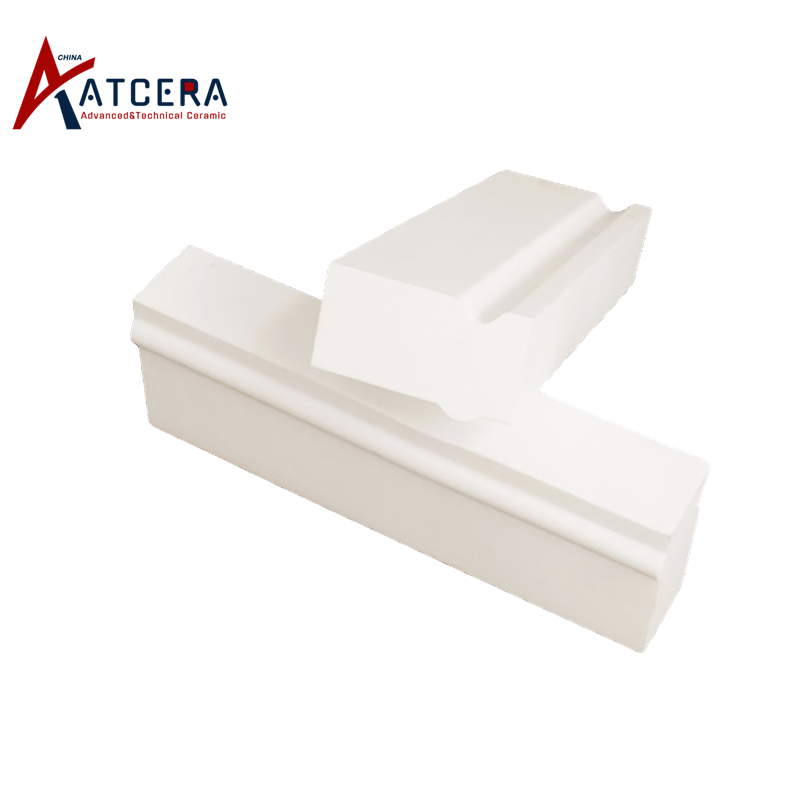

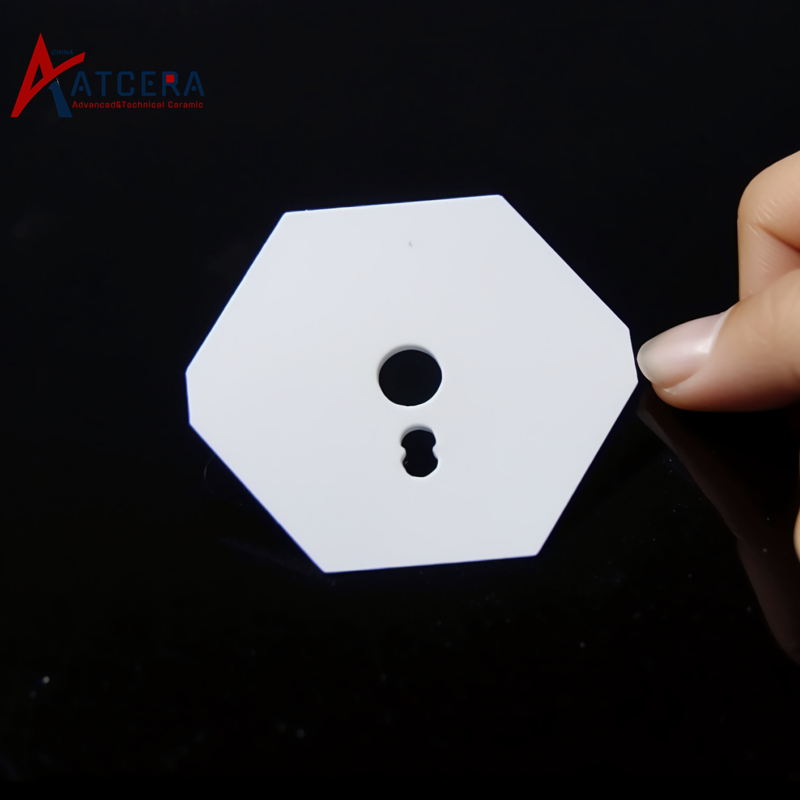

Zirconia toughened alumina (ZTA) ceramic is a common advanced industrial ceramics, with oxidized powder as the main raw material, adding a certain proportion of zirconia powder as a toughening agent, through forming and high temperature sintering process. Compared with alumina, ZTA keeps high hardness, high temperature resistance and corrosion properties, while toughness and tensile strength has been greatly improved. It has important applications in various mechanical equipment, high temperature fire resistance, petrochemical industry, compared with zirconia the material density is small, with light weight, also the cost is lower.

| View all ZTA products |

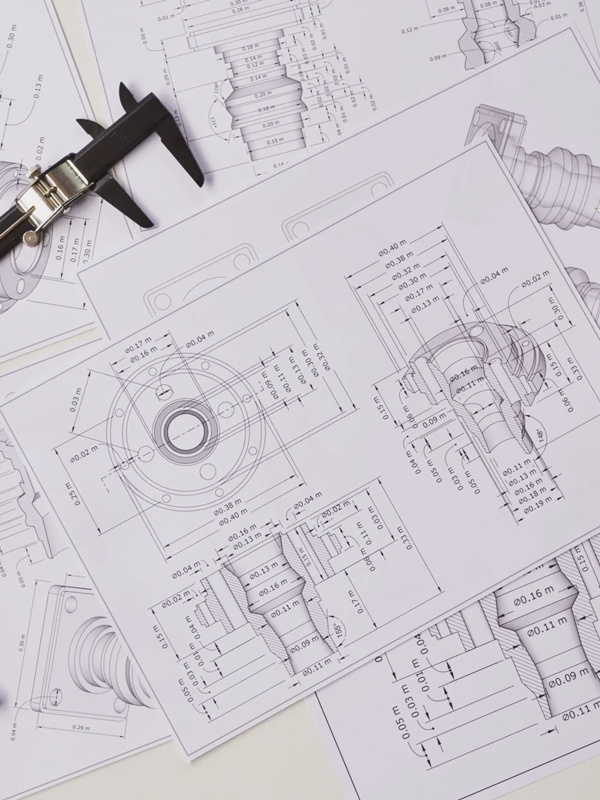

According to your application scenario, analyze the needs, choose the appropriate material and processing plan.

According to your application scenario, analyze the needs, choose the appropriate material and processing plan. Professional team, quick response, can provide solutions and quotations within 24 hours after confirming the demand.

Professional team, quick response, can provide solutions and quotations within 24 hours after confirming the demand. Flexible business cooperation mechanism, support at least one piece of quantity customization.

Flexible business cooperation mechanism, support at least one piece of quantity customization. Quickly provide samples and test reports to confirm that the product meets your needs.

Quickly provide samples and test reports to confirm that the product meets your needs. Provide product use and maintenance suggestions to reduce your cost of use.

Provide product use and maintenance suggestions to reduce your cost of use.