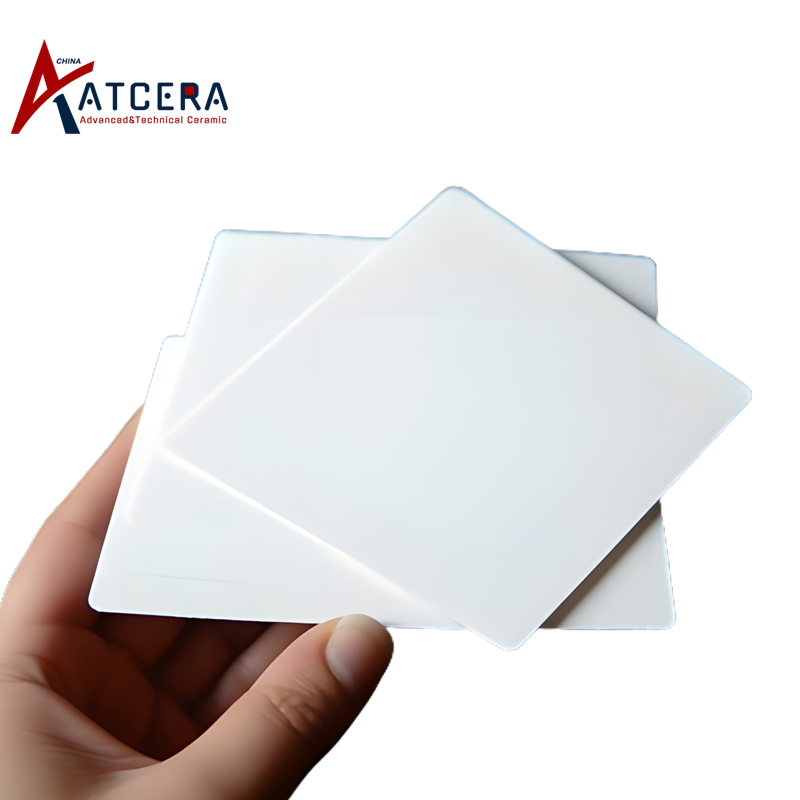

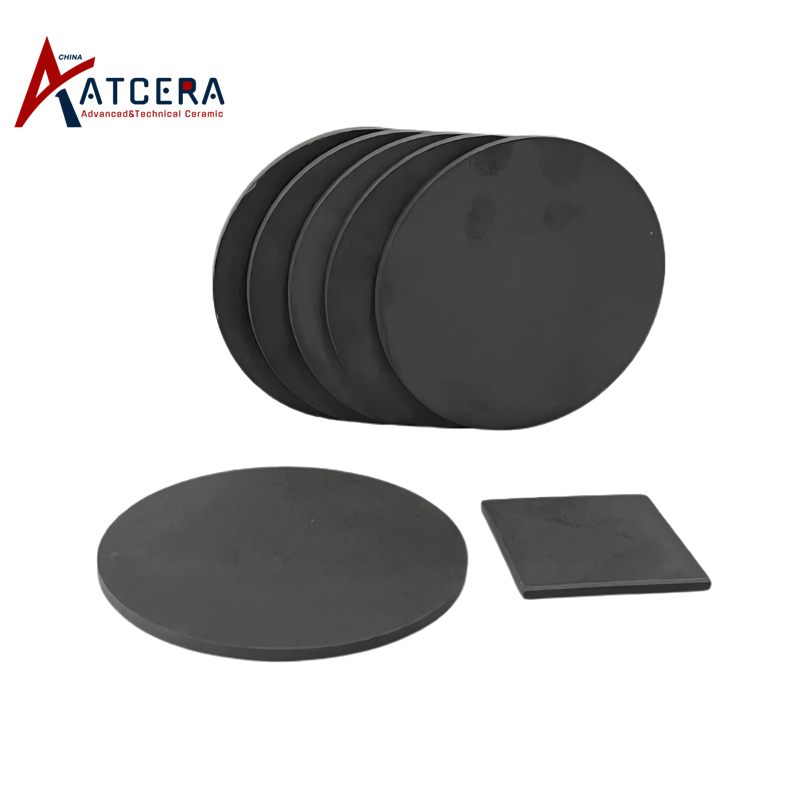

Alumina substrate has excellent thermal conductivity and insulation, as well as with high mechanical strength and hardness, good heat shock performance characteristics, widely used in power devices, hybrid integrated circuits and multi-chip modules and other fields.

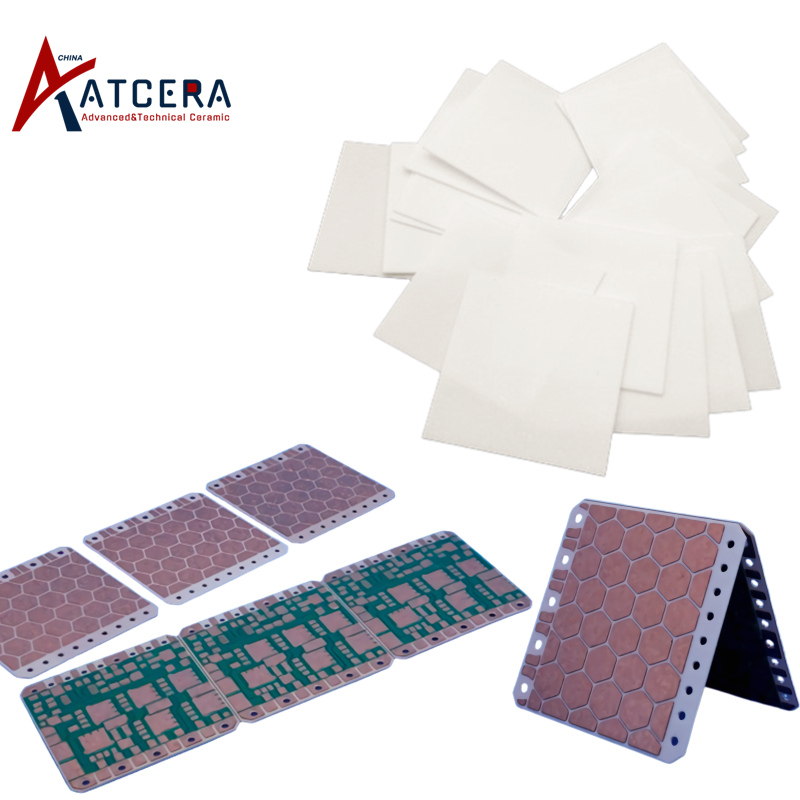

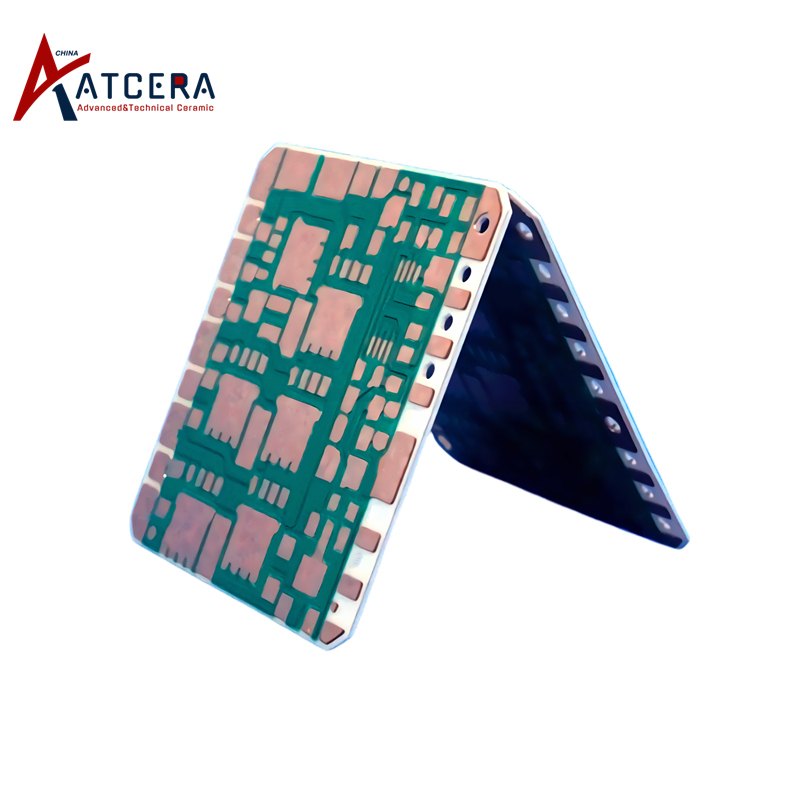

Alumina ceramic metalized substrates are ceramic copper-clad plates with electrical conductivity, thermal conductivity, and high insulation properties, formed by metalizing alumina ceramic substrates with copper. The alumina metalized substrates can be processed through various techniques. When combined with the DBC (direct bond copper) process, they become DBC aluminum ceramic copper-clad substrates. Similarly, when integrated with the DPC (direct plated copper) process, they transform into DPC aluminum ceramic copper-clad substrates.

| view all alumina substrates |