1. Mechanical engineering industry

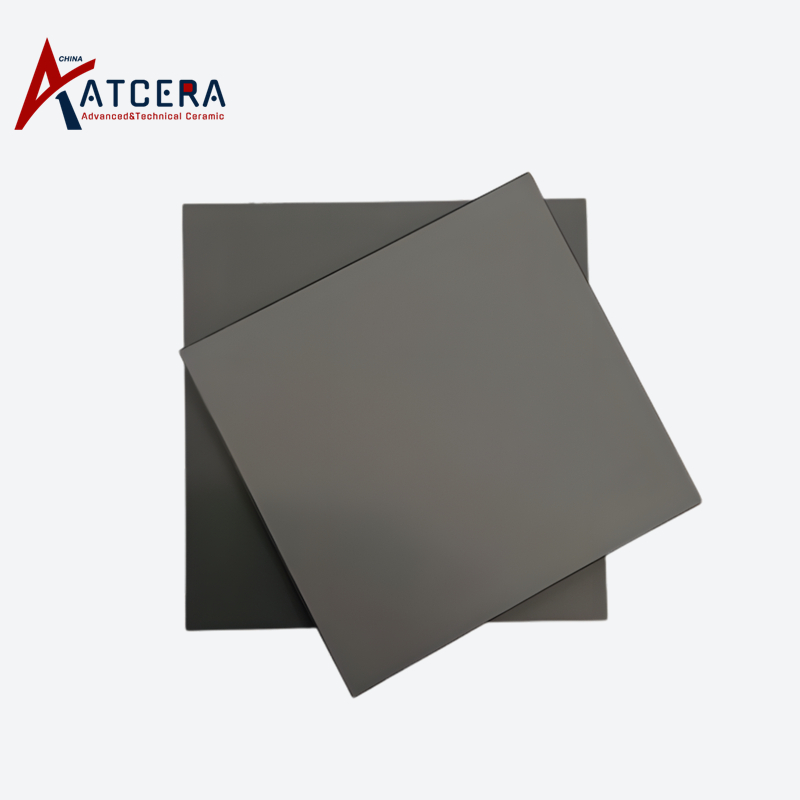

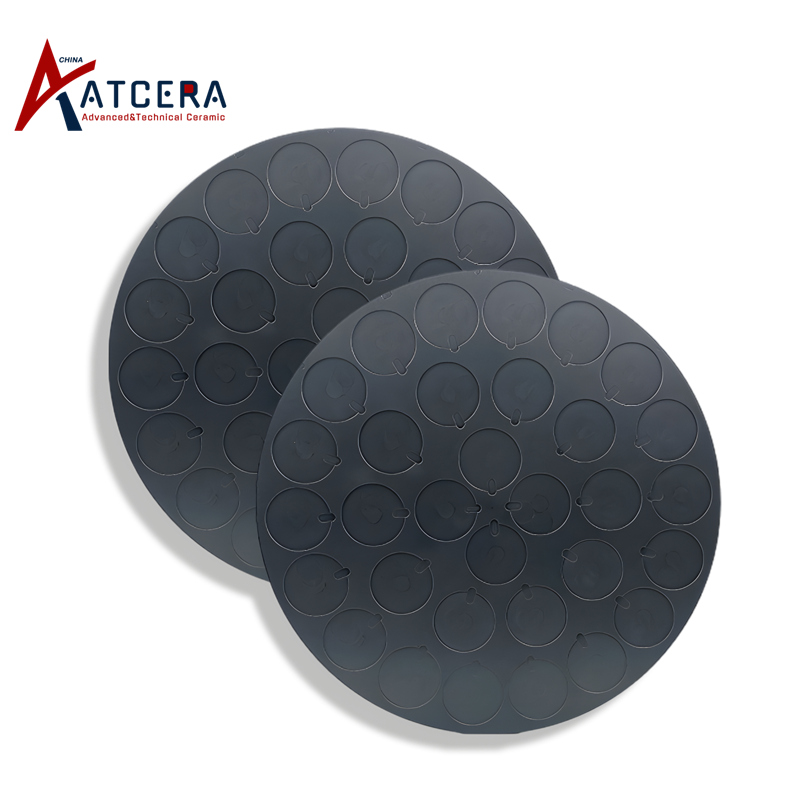

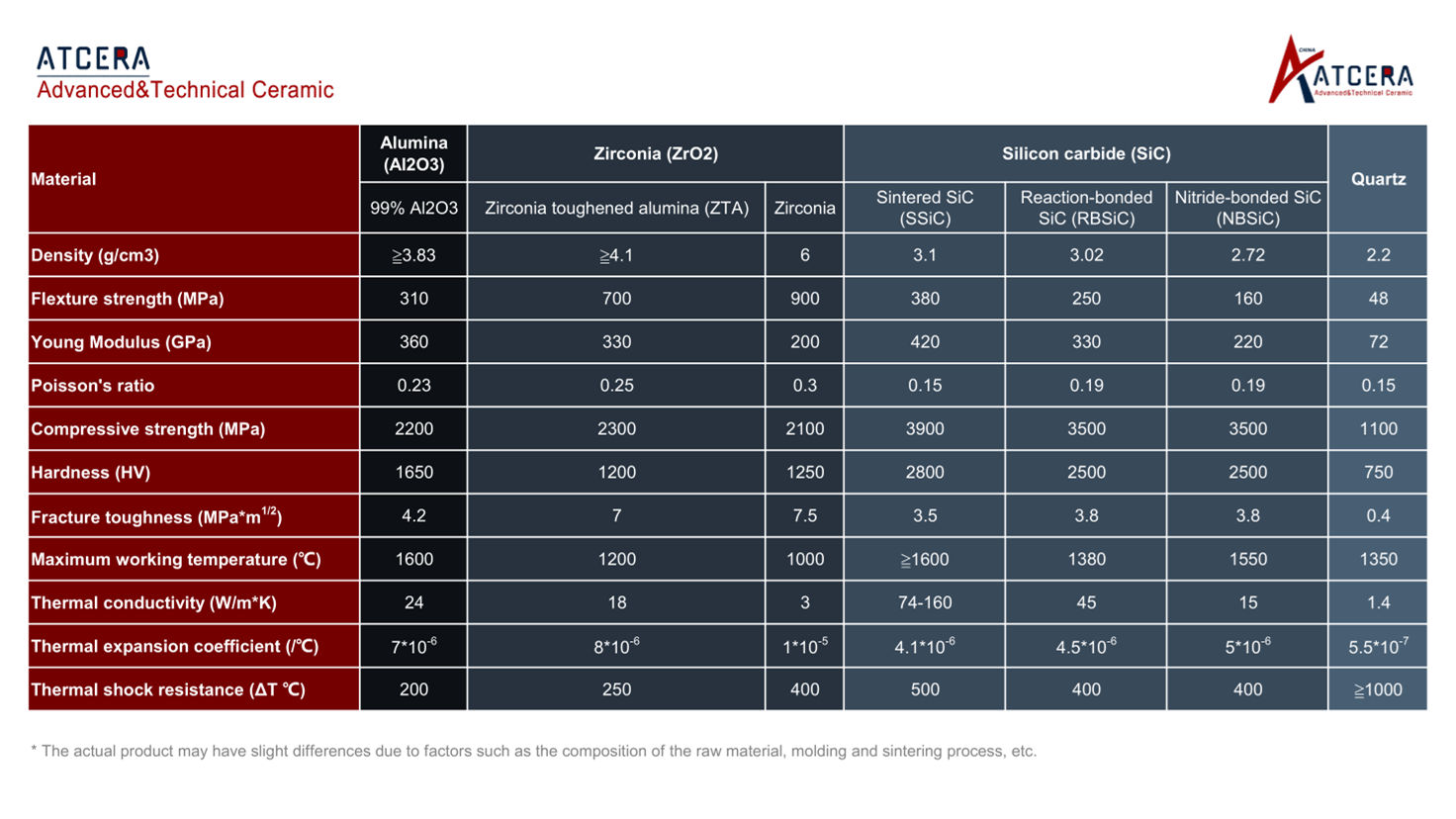

Alumina plates and zirconia plates have high hardness, good wear resistance, also with good mechanical properties, they can stable performance at high temperature, can be made into various anti-wear components for mechanical devices, such as grinding machine, sand blasting machine, powder delivery pipe system, etc.

2. High temperature refractory industry

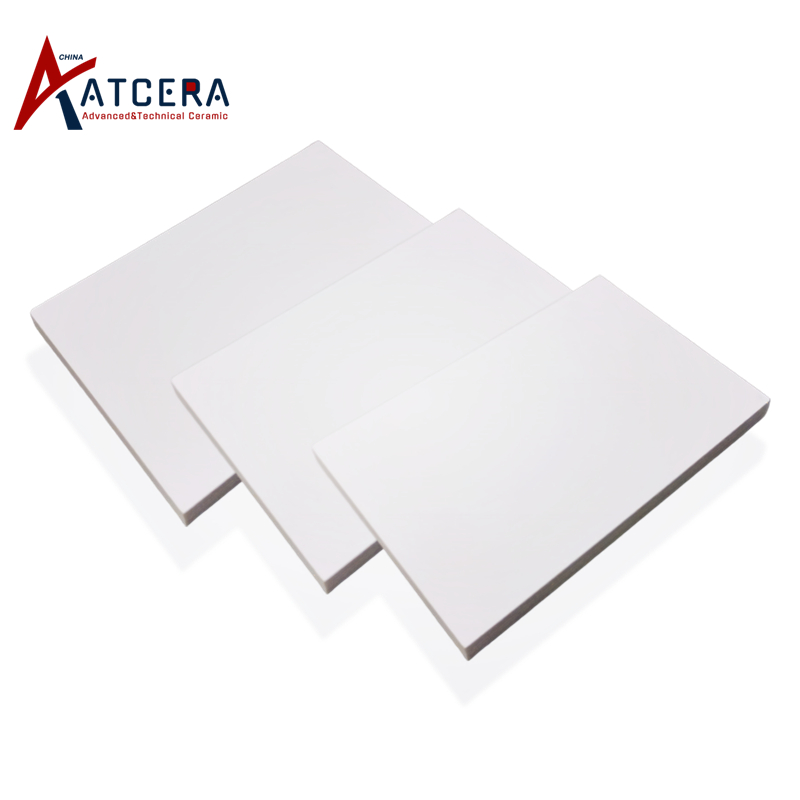

Alumina and ZTA plates have high temperature resistant, oxidation resistant, can maintain stable performance under harsh working conditions, and can be used to manufacture thermal insulation plates for furnace, hot pressing machine, etc.

3. Chemical and metallurgical industries

Alumina, zirconia and silicon carbide plates have very good corrosion resistance, good chemical inertia, and do not react with various chemical media, also with excellent high temperature resistance, they are suitable for manufacturing a variety of chemical and metallurgical equipment, such as reaction vessel, heating plate, etc.

4. Military industry

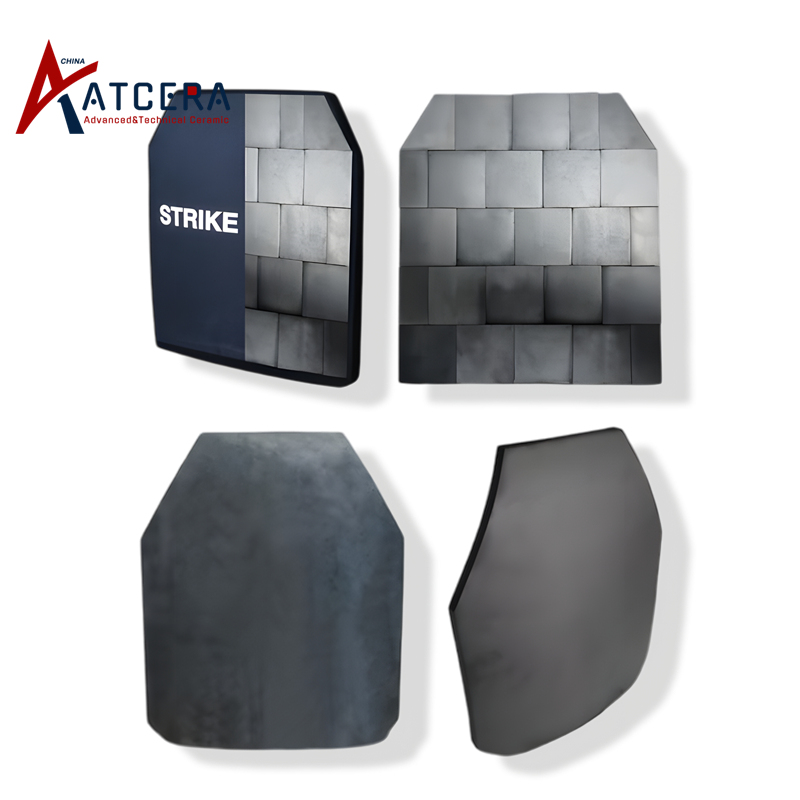

Silicon carbide and alumina plates have high hardness and low density, they can be used to produce body armor liner, as well as protective device for bulletproof vehicle and tank.