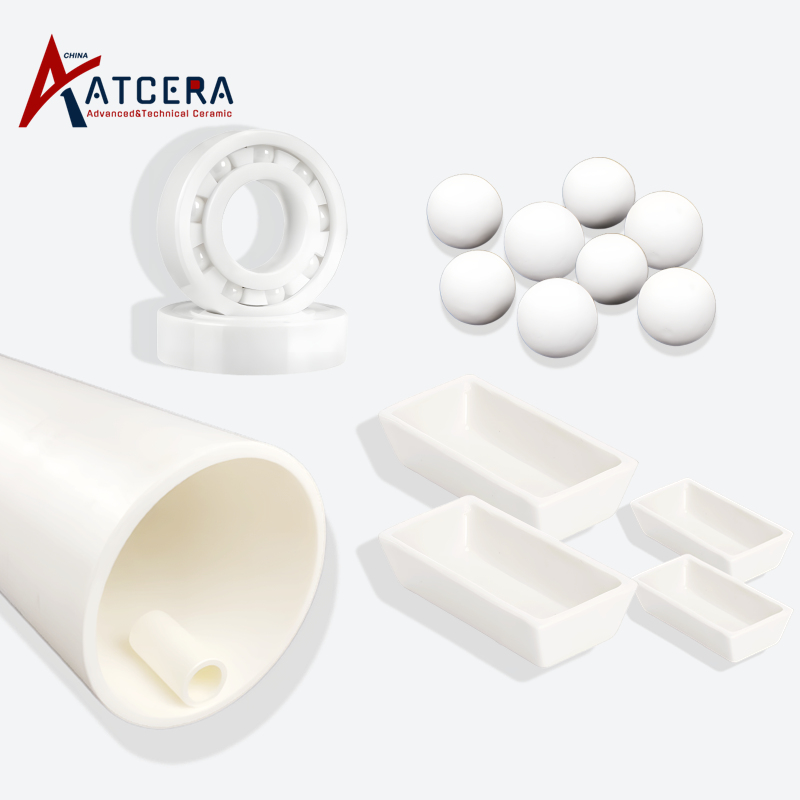

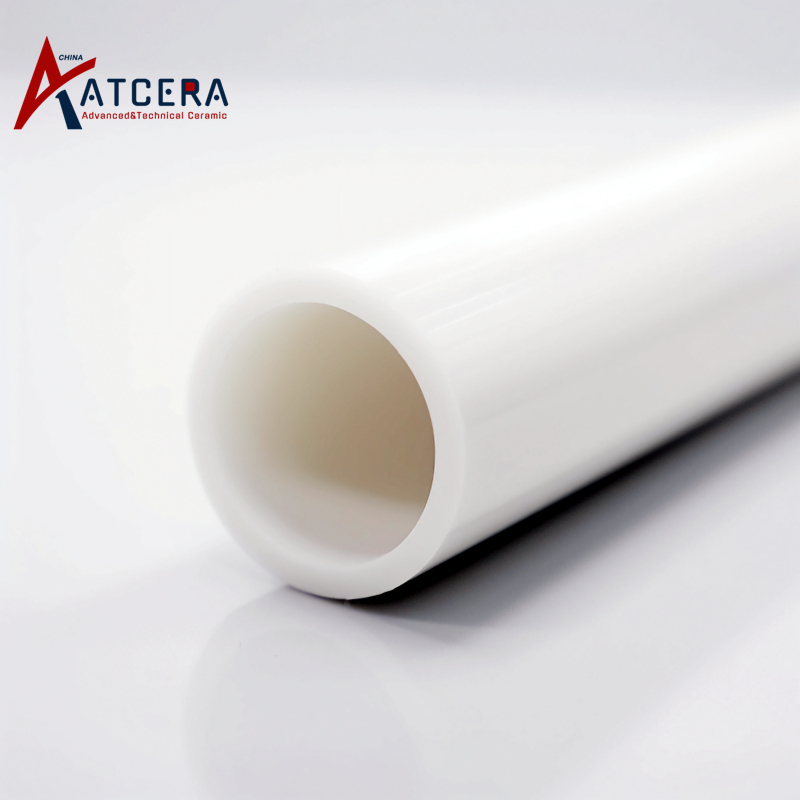

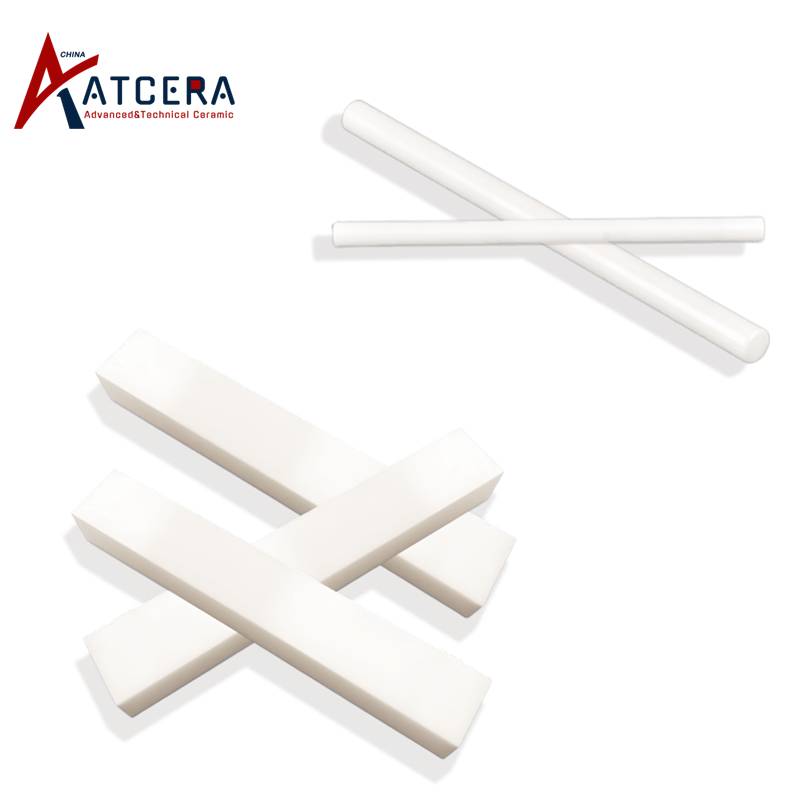

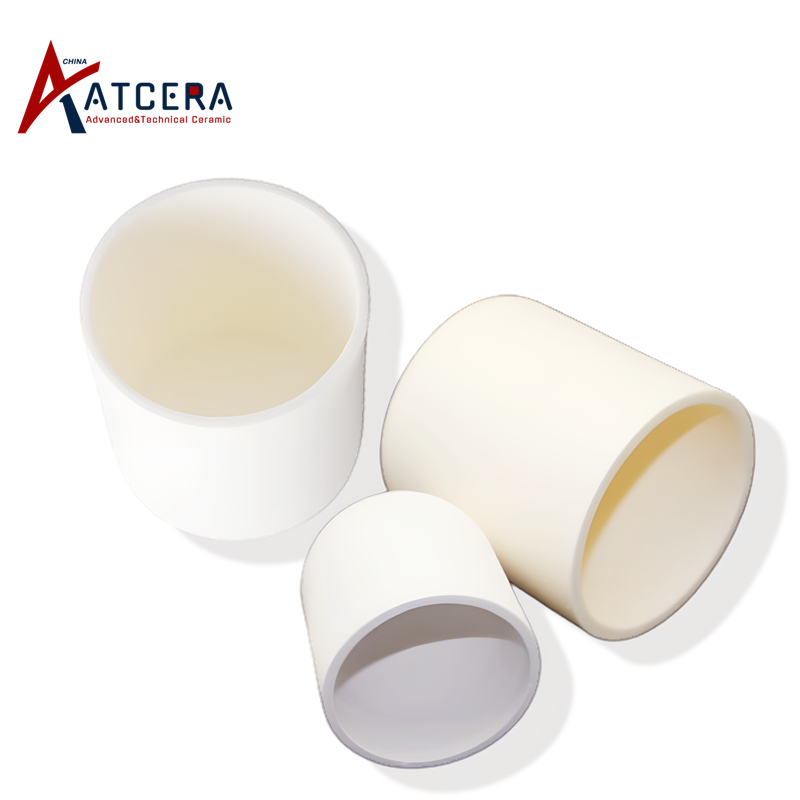

Zirconia ceramics, also known as ZrO₂ ceramic or zirconium oxide ceramic substrates , are made from high-purity zirconia powder with a small amount of stabilizer such as yttrium oxide (Y₂O₃) or magnesium oxide (MgO). After uniform mixing, the material is formed and sintered at high temperatures to achieve a stable crystal phase ceramic structure. Zirconia ceramics are widely valued for their High-temperature resistance, excellent thermal shock resistance, superior hardness, good wear and corrosion resistance, and exceptional toughness, earning them the nickname “ceramic steel.” These properties make ZrO₂ ceramic highly versatile and suitable for applications in mechanical engineering, petrochemical industries, electronic appliances, medical and biological fields, as well as precision instruments and meters. Their comprehensive performance, durability, and reliability continue to drive advancements in various industrial and technological sectors.

| view all zirconia ceramic products |