Silicon carbide substrate is the basic material of semiconductor chips, compared with silicon substrate, it can better meet the needs of high temperature, high voltage, high frequency and large power, and it is widely used in electric vehicles, photovoltaic power generation, rail transit, data centers, charging piles and other products and equipment.

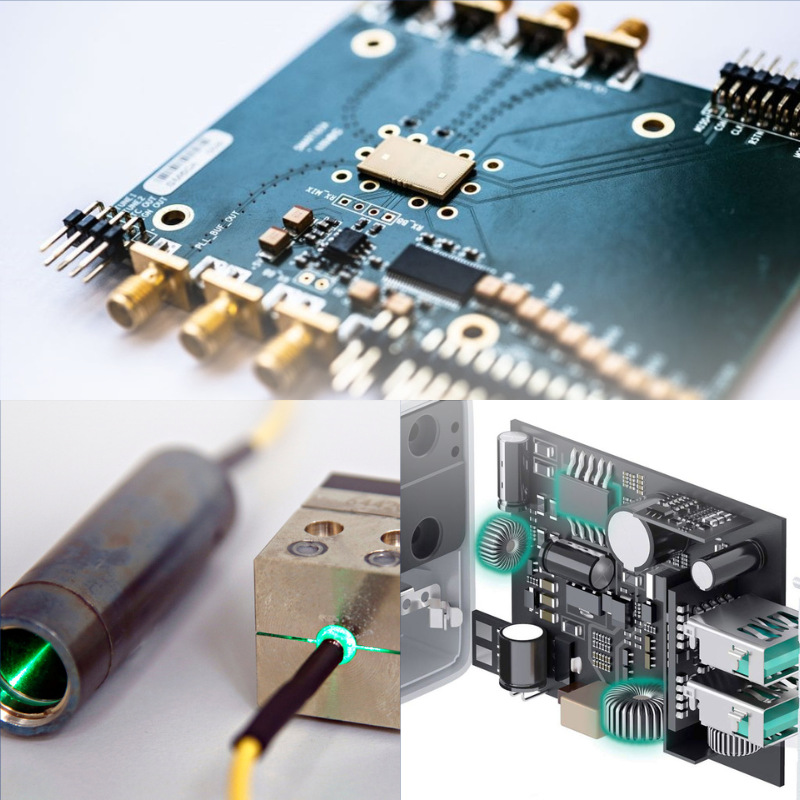

1. High-power devices (conductive type)

Silicon carbide substrate has high thermal conductivity, high breakdown electric field strength, low energy loss, suitable for the production of high-power devices, such as power modules, drive modules, etc.

2. Radio frequency electronic devices (semi-insulated type)

Silicon carbide substrate has high conductivity, can meet the needs of high-frequency work, suitable for RF power amplifiers, microwave devices and high-frequency switches;

3. Photoelectronic devices (semi-insulated type)

Silicon carbide substrate has a wide energy gap and high thermal stability, suitable for production of photodiodes, solar cells and laser diodes and other devices;

4. Temperature sensor (conductive type)

Silicon carbide substrate has high thermal conductivity and thermal stability, suitable for production of wide working range and high-precision temperature sensor.