1. Mechanical engineering

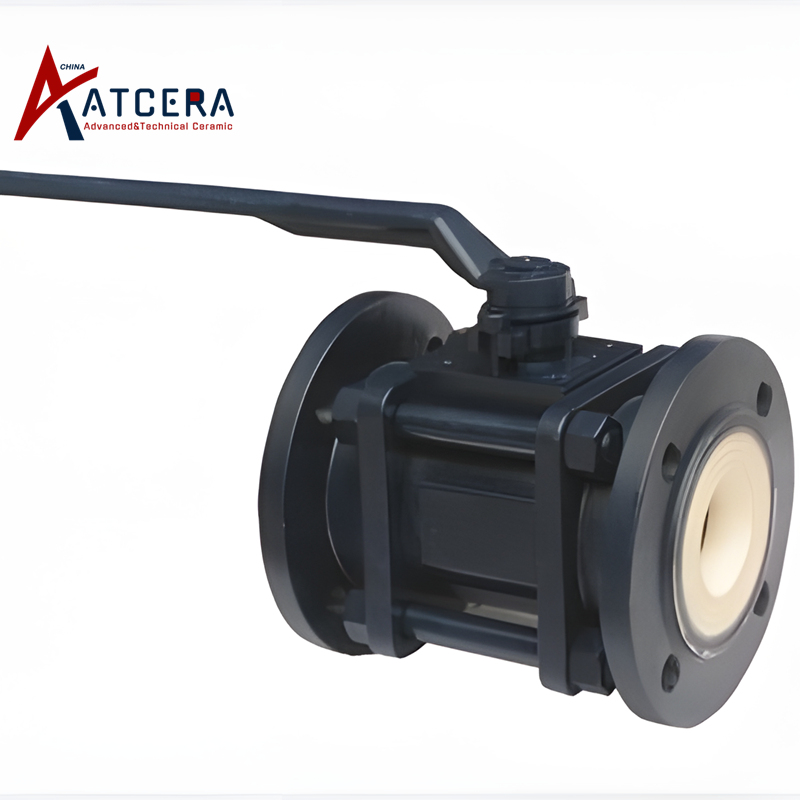

Alumina and zirconia ceramic valvse have high strength, good wear resistance, long life time, can be used in hydraulic system, lubricating oil system, fuel system and air conditioning refrigerant system to control liquid flow and direction, or to achieve flow shut off.

2. Petrochemical

Alumina and zirconia ceramic valve has good corrosion resistance and can be used to control transportation and flow of crude oil, refined oil, chemical liquids etc.

3. Pharmaceutical biology

Biological inertia of zirconia valve is good, no pollution to liquid, can be used to control the liquid flow in the production of drugs and biological agents.

4. Power station

Alumina and zirconia valve has long life, high temperature resistance, and can be used for steam flow control in power generation and other industries.

5. Water supply and HVAC

Alumina and zirconia valves have good wear resistance and long life, and are widely used in urban water supply, air conditioning water and cooling water systems.