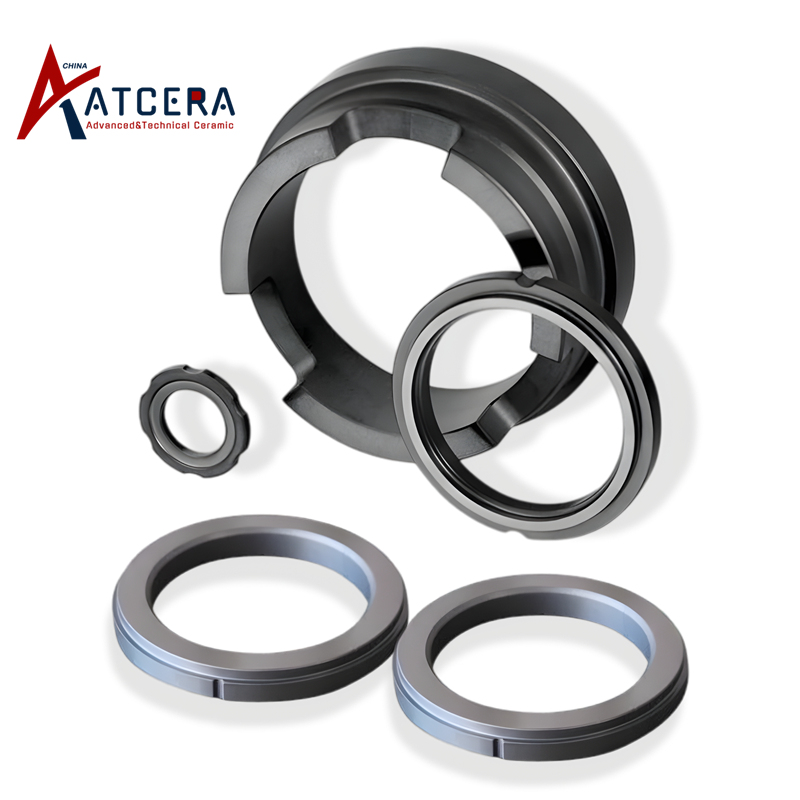

1. Mechanical engineering industry

Alumina ceramics have high hardness, good wear resistance, also with good mechanical properties, it can stable performance at high temperature, can be made into various mechanical parts, such as piston, plunger, shaft, cylinder liner, machining cutting tools, etc.

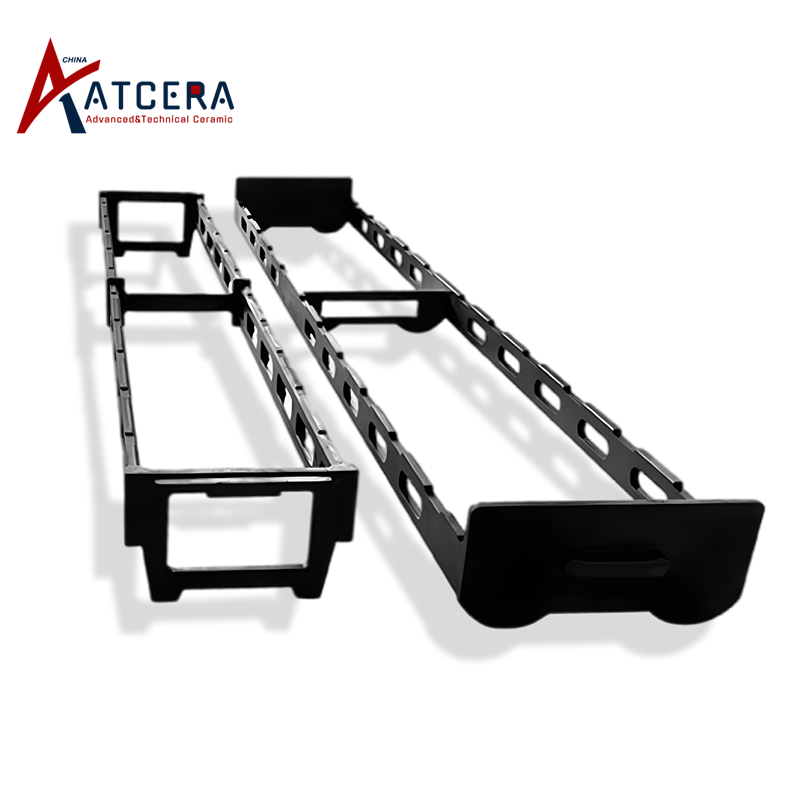

2. Photovoltaic cells and semiconductor production

Alumina have good wear resistance, corrossion and high temperature resistance, it can be used to produce various tools for semiconductor and photovoltaic industry, such as wafer carrying tray, vacuum chuck, wafer boat, wafer boat bracket, etc.

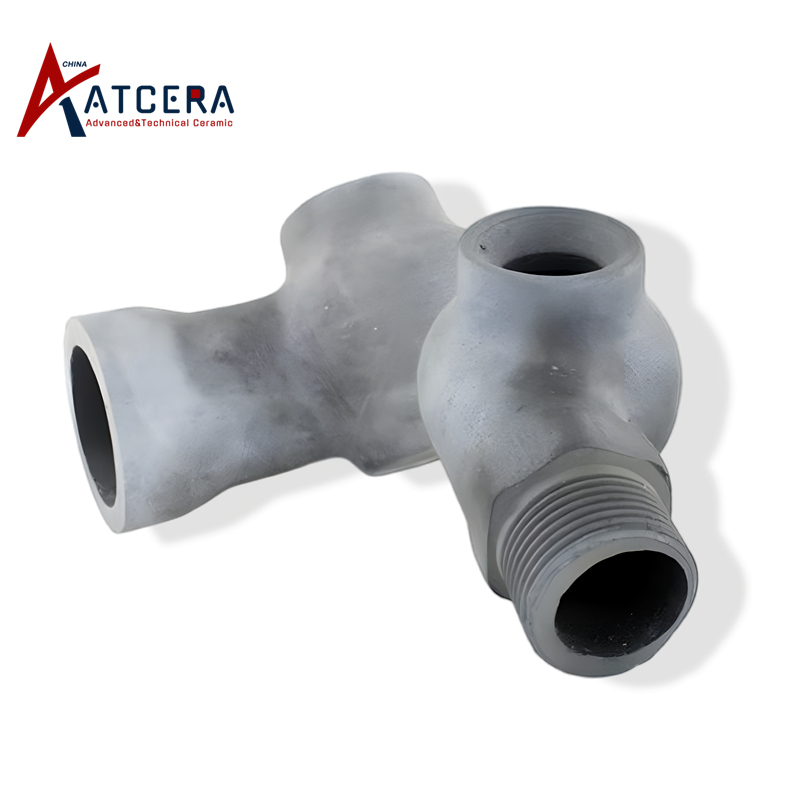

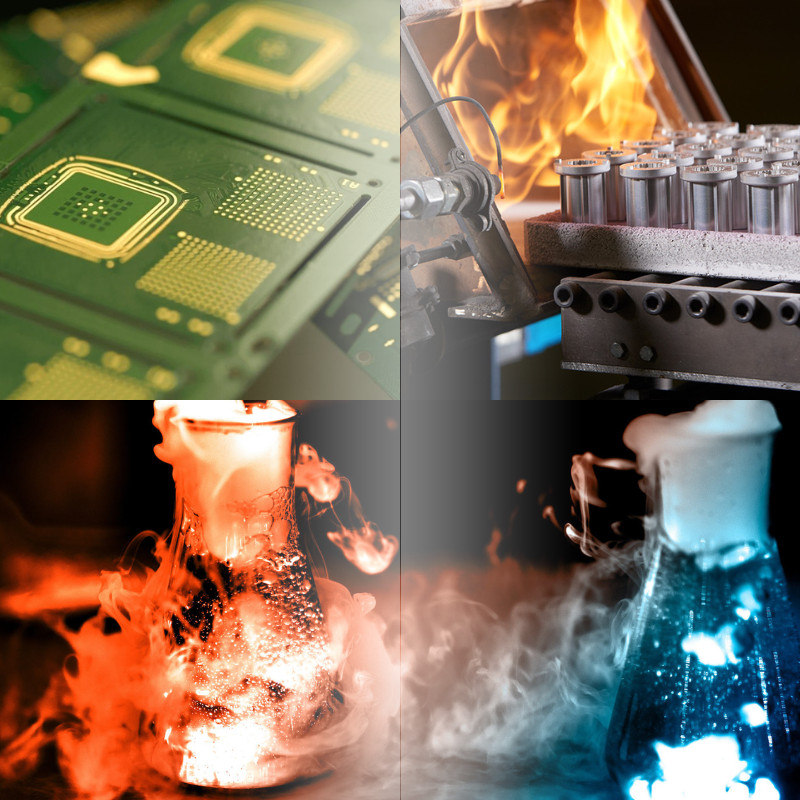

3. High temperature refractory industry

Alumina ceramics have high temperature resistant and oxidation resistant, it can maintain stable performance under harsh working conditions, and can be used to manufacture heater and heating element, nozzle, mold for glass products, etc.

4. Experiment and measurement device

Alumina has good wear resistance and high temperature and corrosion resistance, they can used to produce various experiment and measurement device, such as gauge, cuvette testing tube, culture dish reaction vessel, etc.