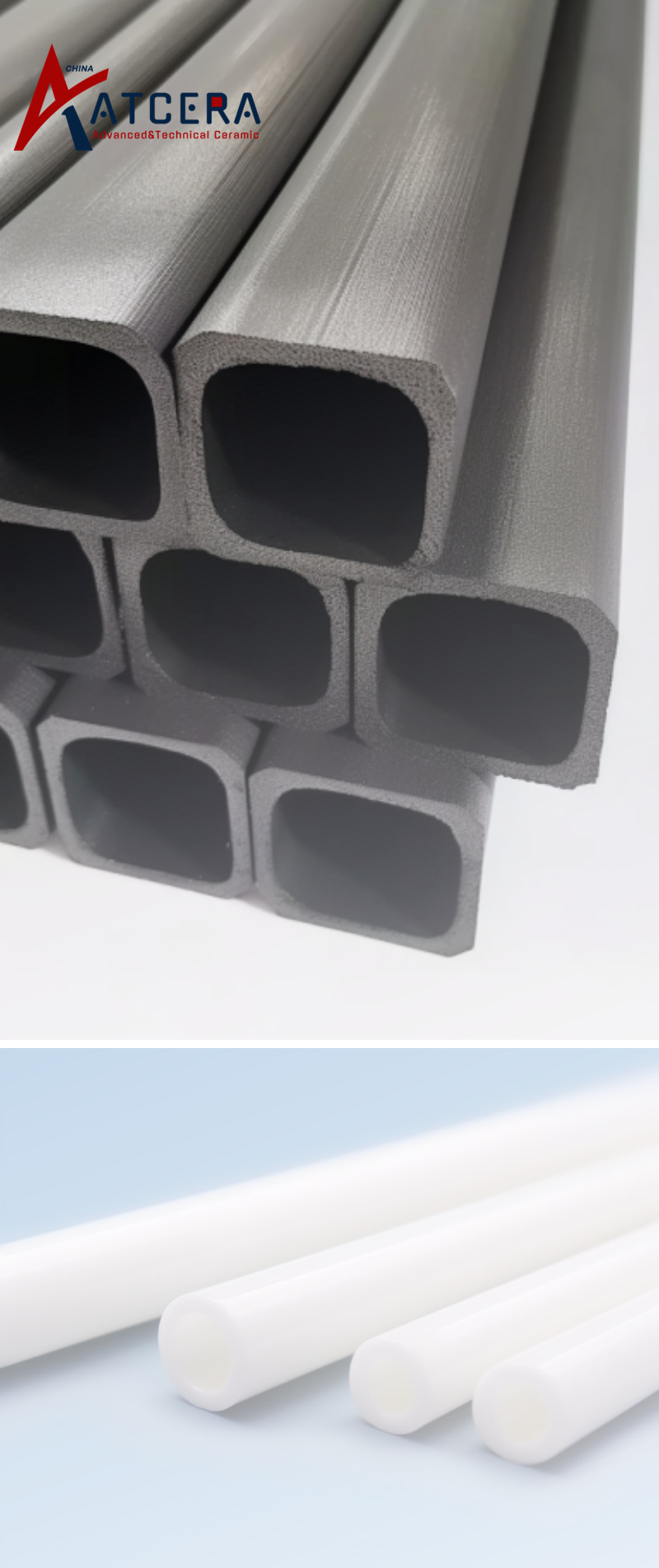

1. Mechanical engineering industry

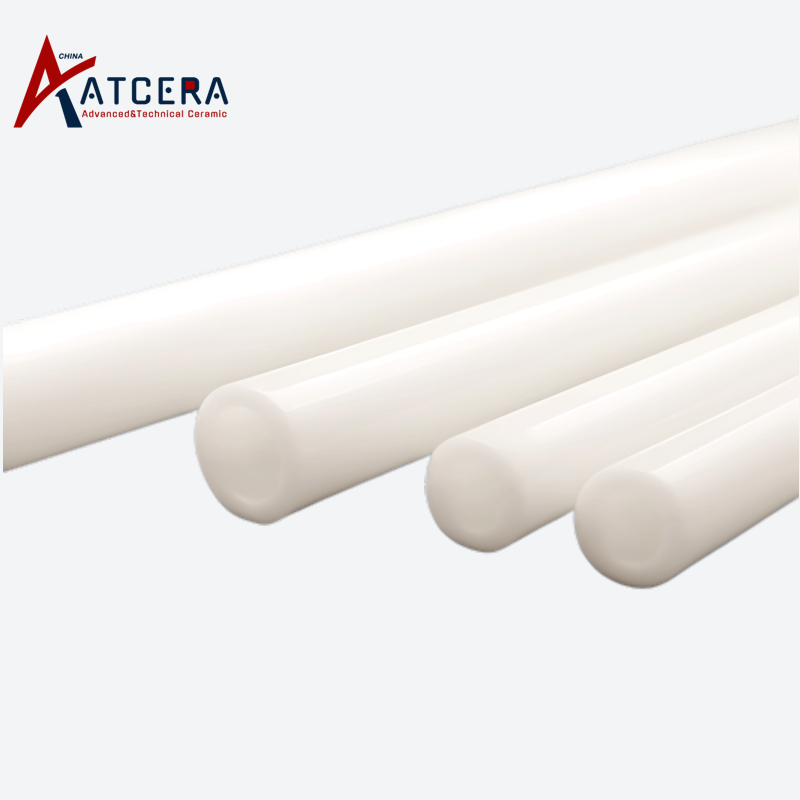

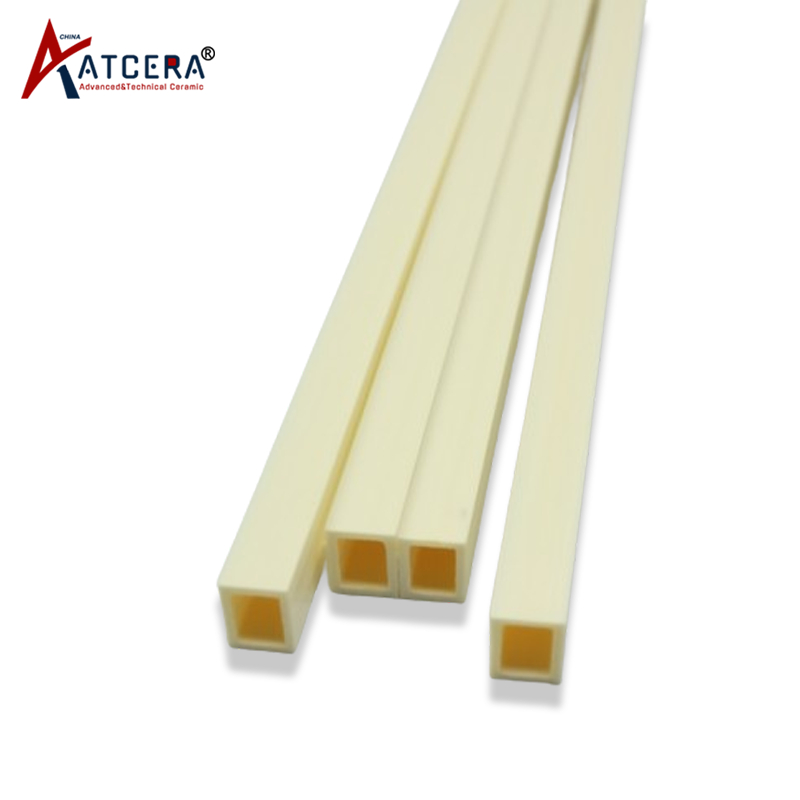

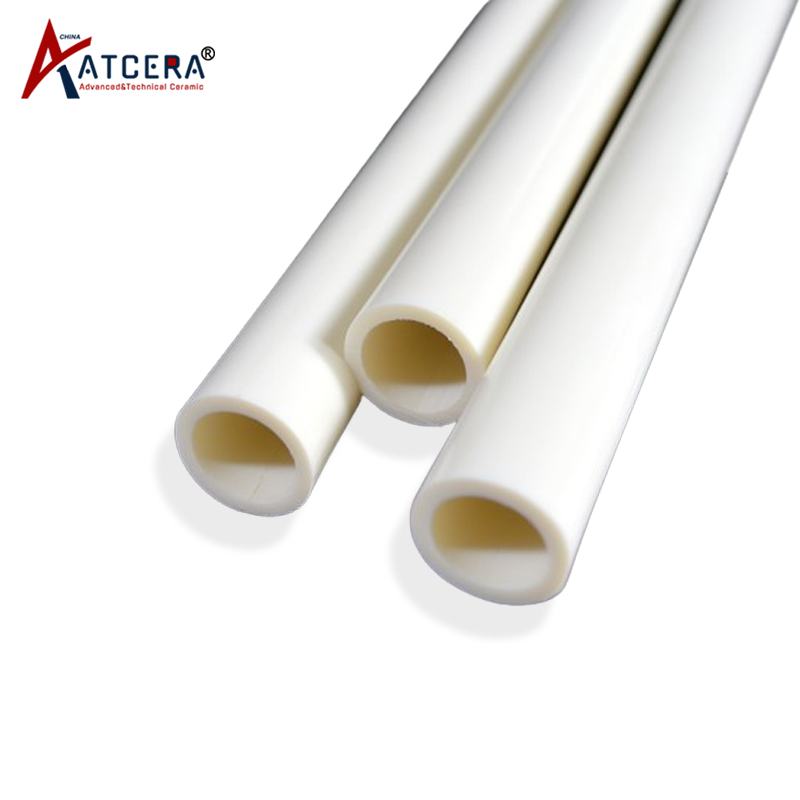

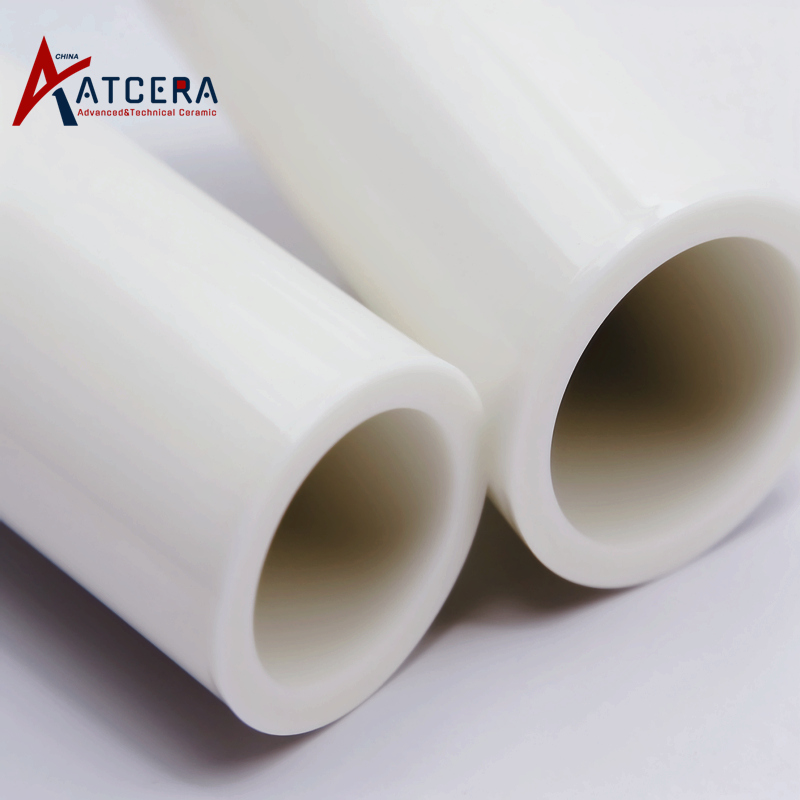

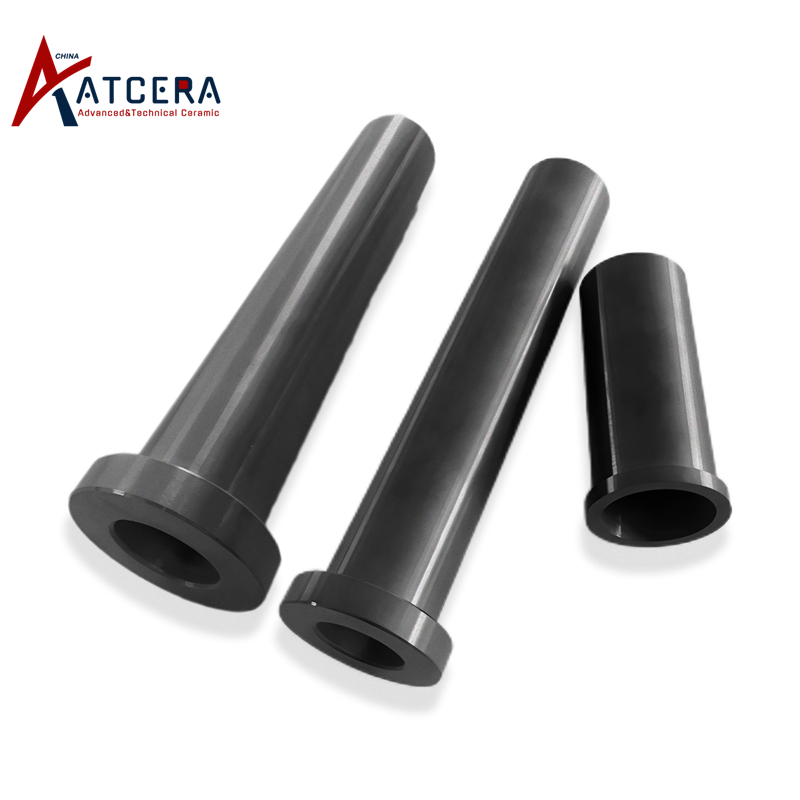

Alumina, zirconia, silicon nitride ceramic tubes have high hardness, good wear resistance, also with good mechanical properties, they can stable performance at high temperature, can be made into various mechanical parts, such as connecting rod, plunger, hydraulic cylinder, etc.

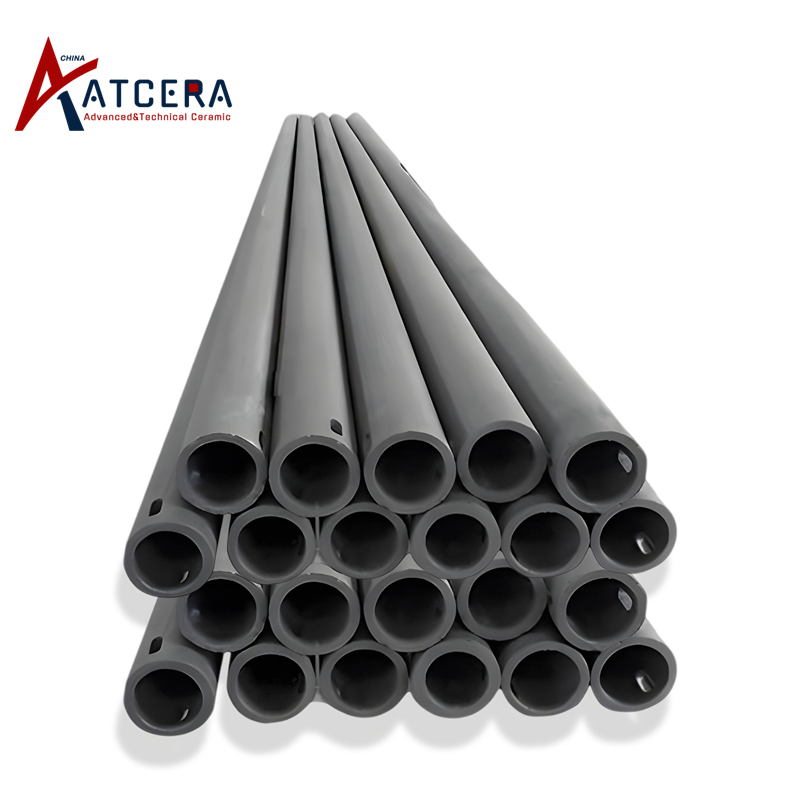

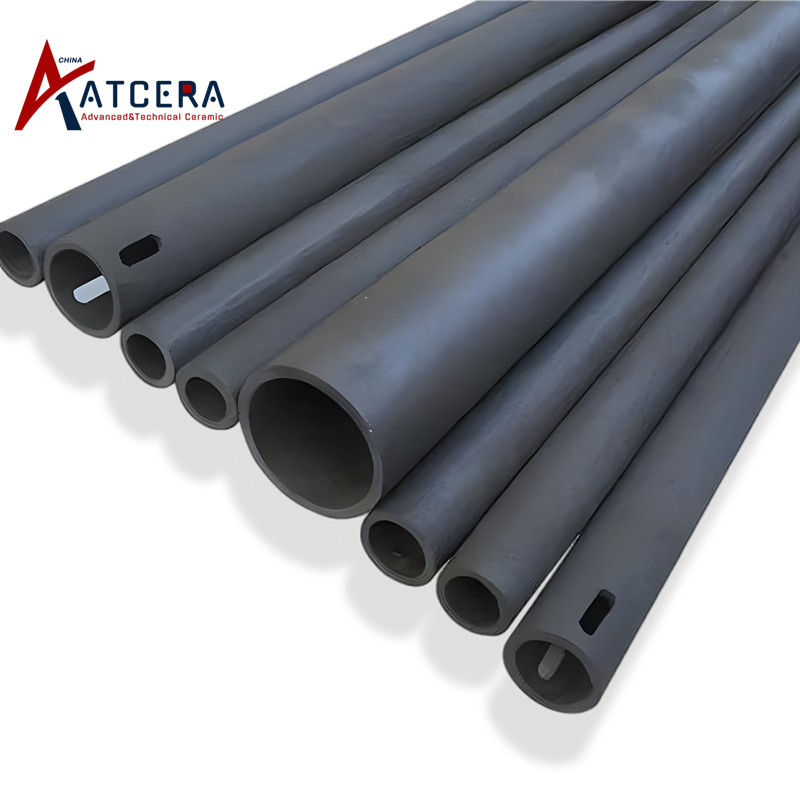

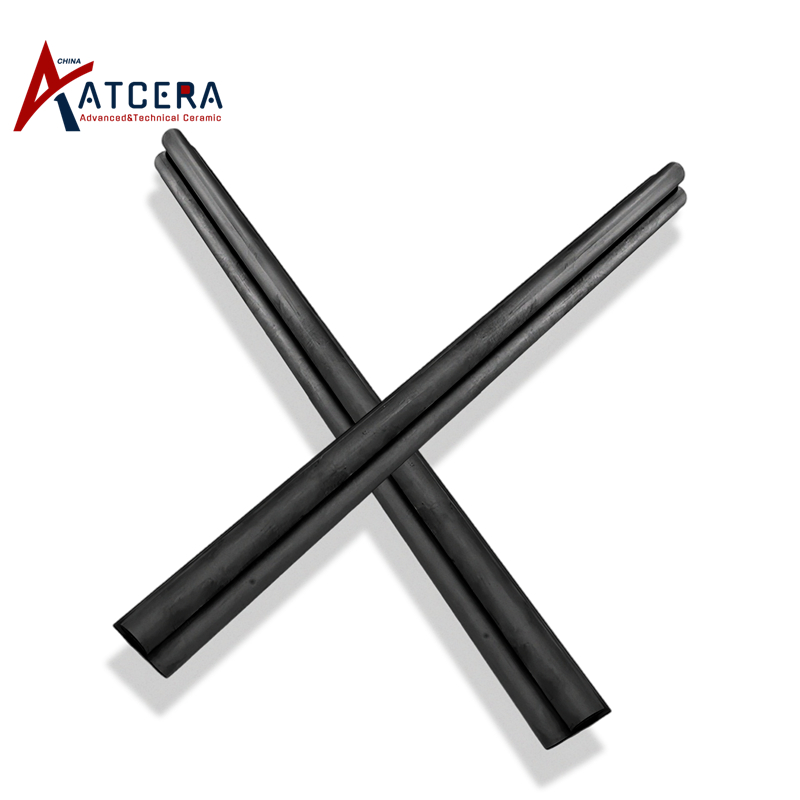

2. High temperature refractory industry

Silicon carbide and silicon nitride tubes have high temperature resistant, oxidation resistant, can maintain stable performance under harsh working conditions, and can be used to manufacture combustion tube, heating tube, heat exchange tube, thermocouple protection tube, etc.

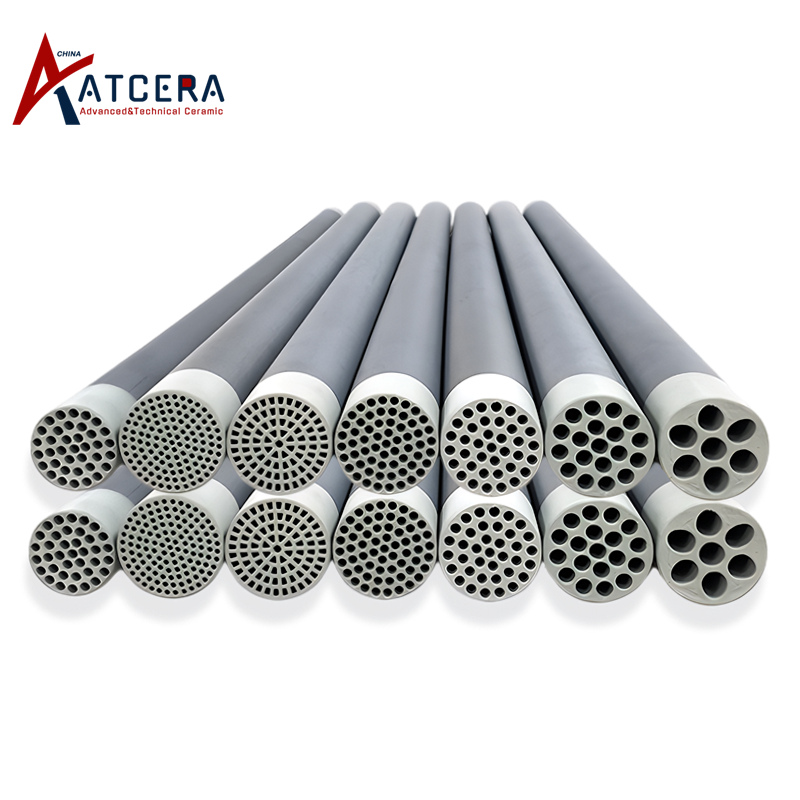

3. Chemical and metallurgical industries

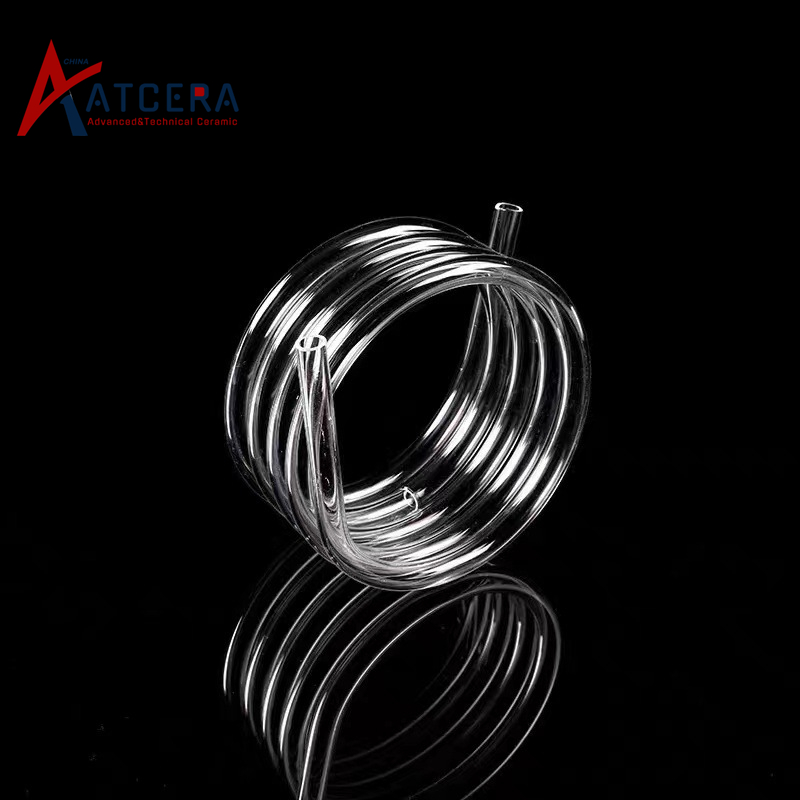

Alumina and silicon carbide and other ceramic tubes have very good corrosion resistance, good chemical inertia, and do not react with various chemical media, meanwhile the surface finish of the ceramic tube is high, the fluid transport resistance is small, can be used to make pipes to transport chemical liquids, as well as filter membrane tubes for chemical process.

4. Medical and biological industries

Alumina and zirconia ceramic tubes have good bioinert and compatibility, non-toxic and harmless, non-radioactive and anti-corrosion, they are widely used in the medical and biological industries to make syringes, tubular filters, biological experimental equipment, etc.

5. Electronic and electrical industry

Alumina ceramic tube has excellent insulation performance, high breakdown resistance voltage, high mechanical strength, good heat dissipation, mainly used in the manufacture of electronic components base and circuit insulation components, as well as high-power electronic device housing.

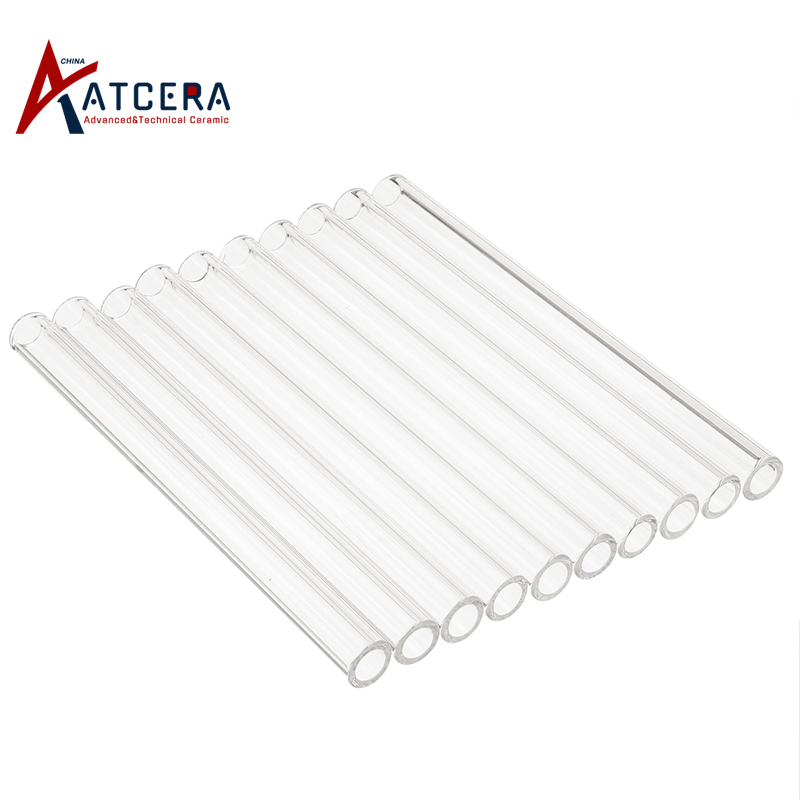

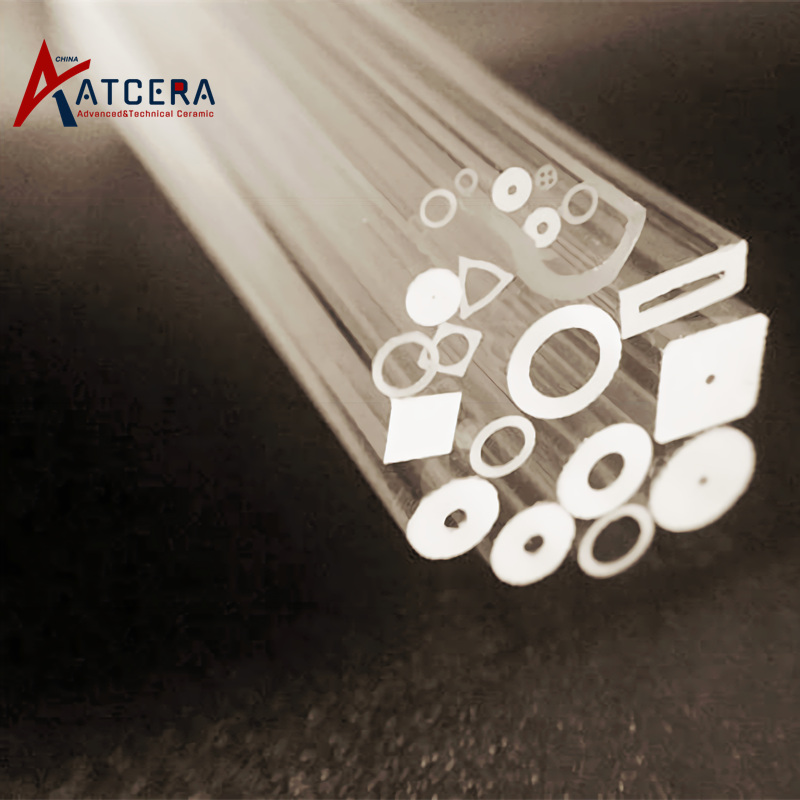

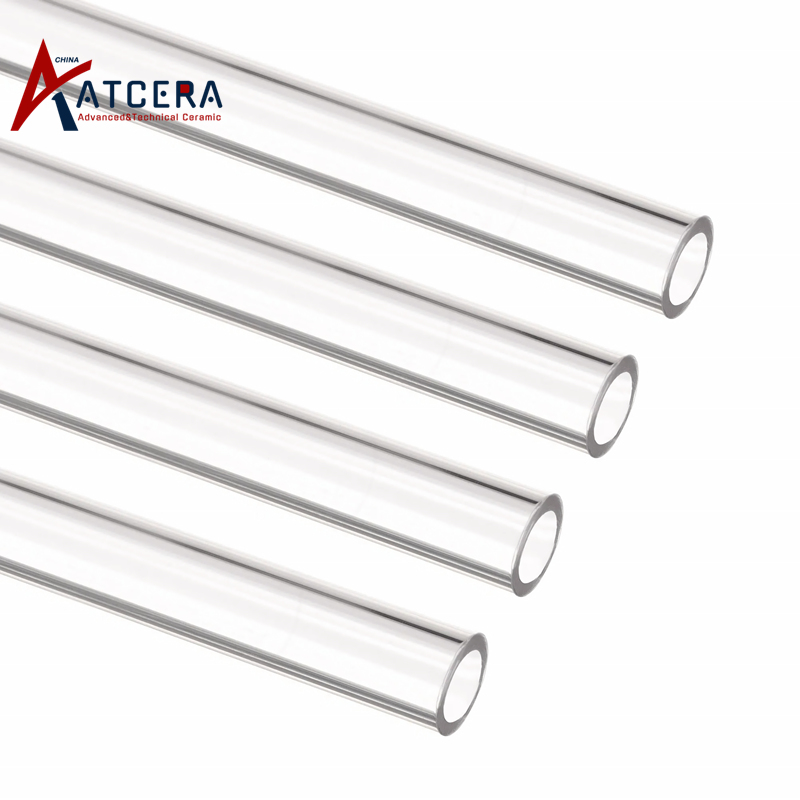

6. Optical components

Quartz tube has good optical properties, high light transmission efficiency, it can be used to make various light source tubes, such as laser tubes, mercury tubes, tungsten iodide tubes, etc.