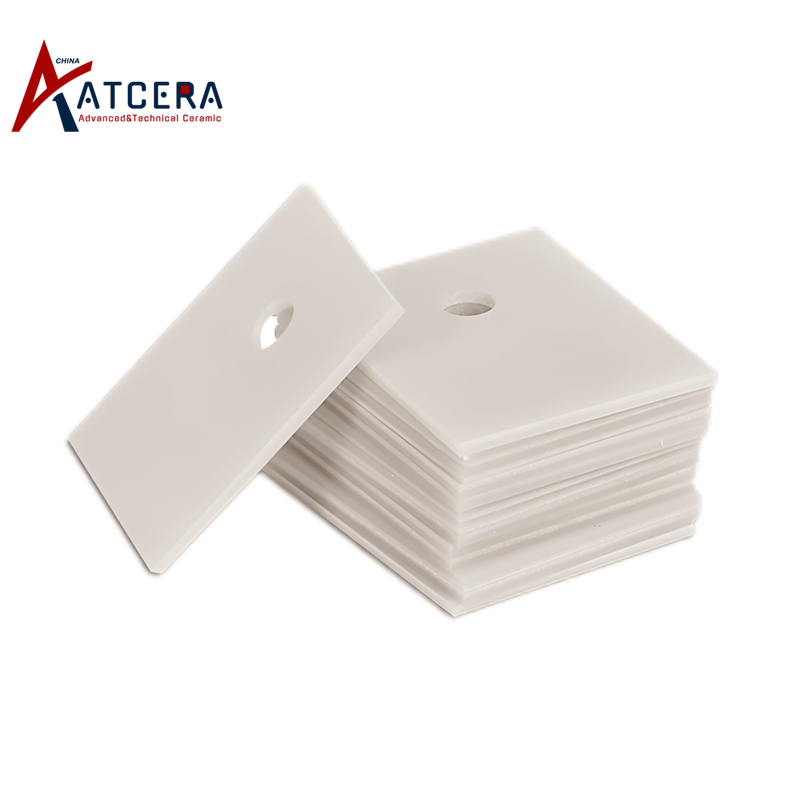

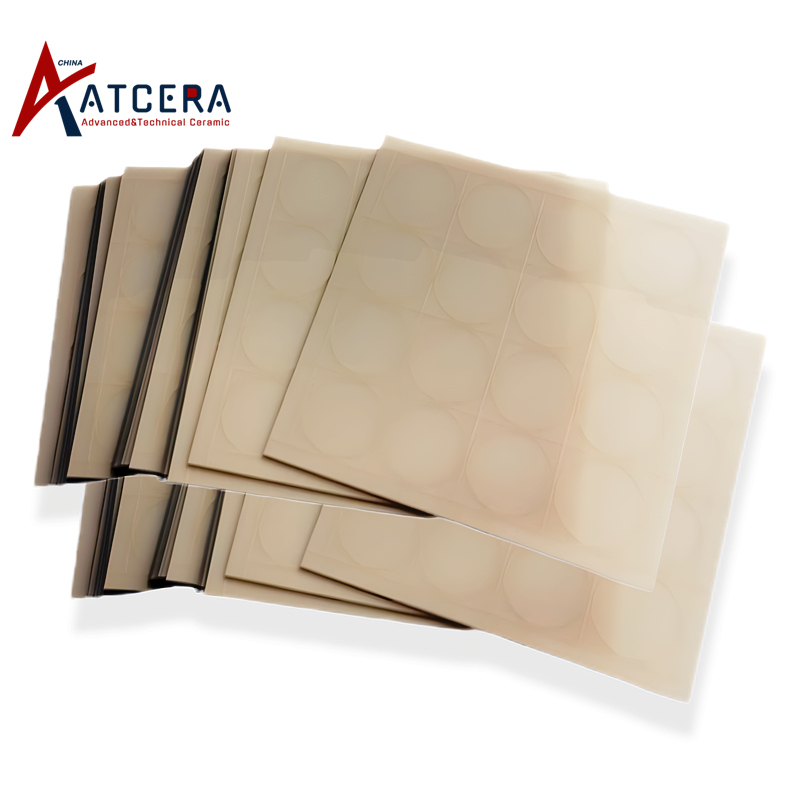

Aluminum nitride ceramic substrate has excellent thermal conductivity performance, it is mainly used in semiconductor, electronics and other microelectronics device manufacturing, as the substrate of chips and electronic components, including integrated circuit (IC), radio frequency (RF) devices, piezoelectric components, photoelectric components, sensors, MEMS and other micro electronic devices. As a high-performance material, aluminum nitride ceramic substrate can provide a stable support platform to ensure normal operation and performance of the components.

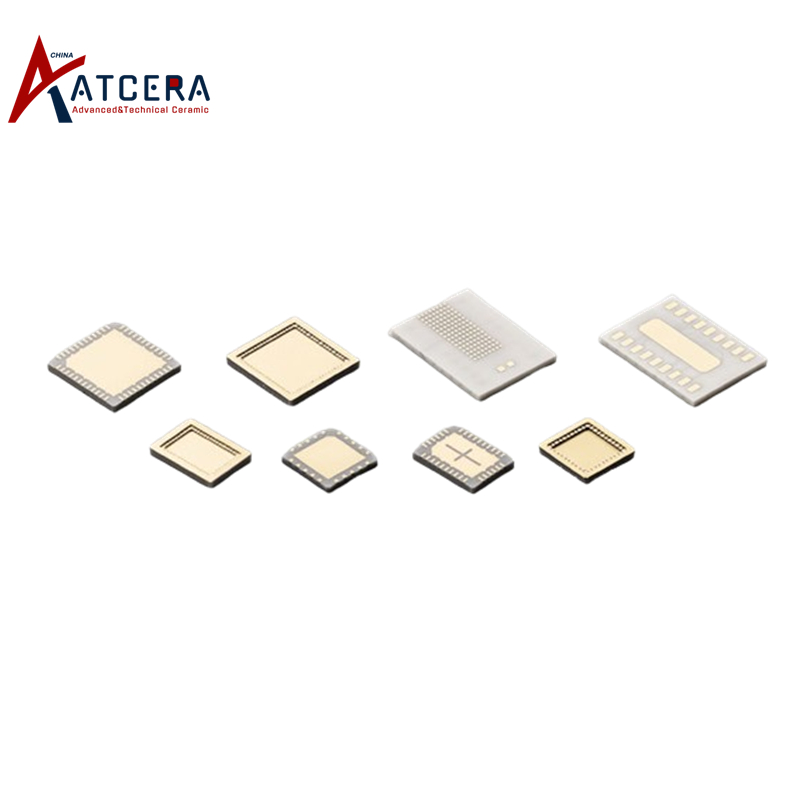

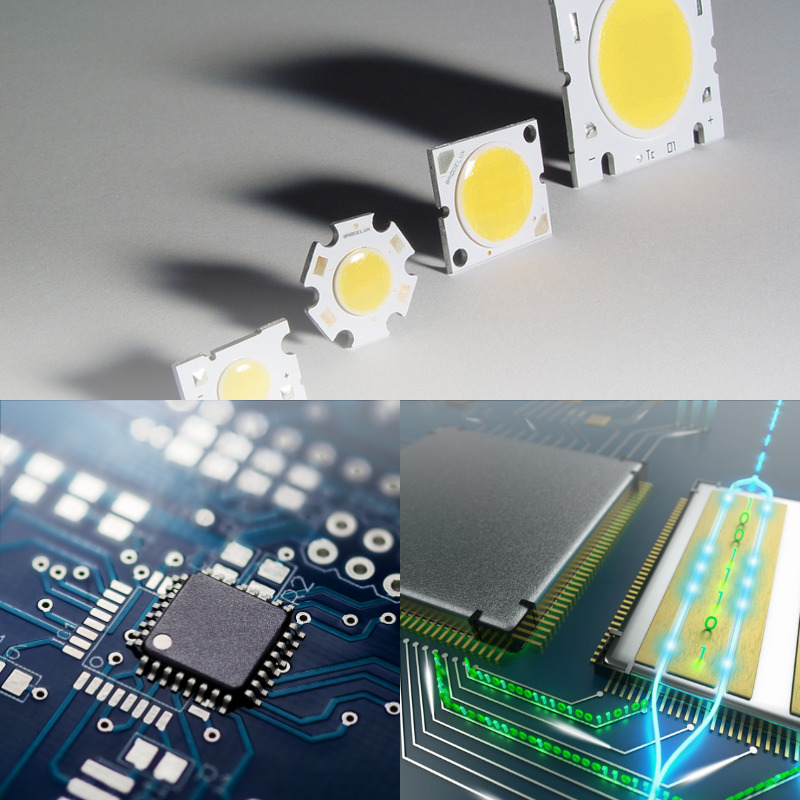

1. LED Chip

Aluminum nitride ceramic substrate has excellent thermal conductivity and mechanical strength, can be used to manufacture high-brightness LED chip, greatly improve the luminous efficiency of LED.

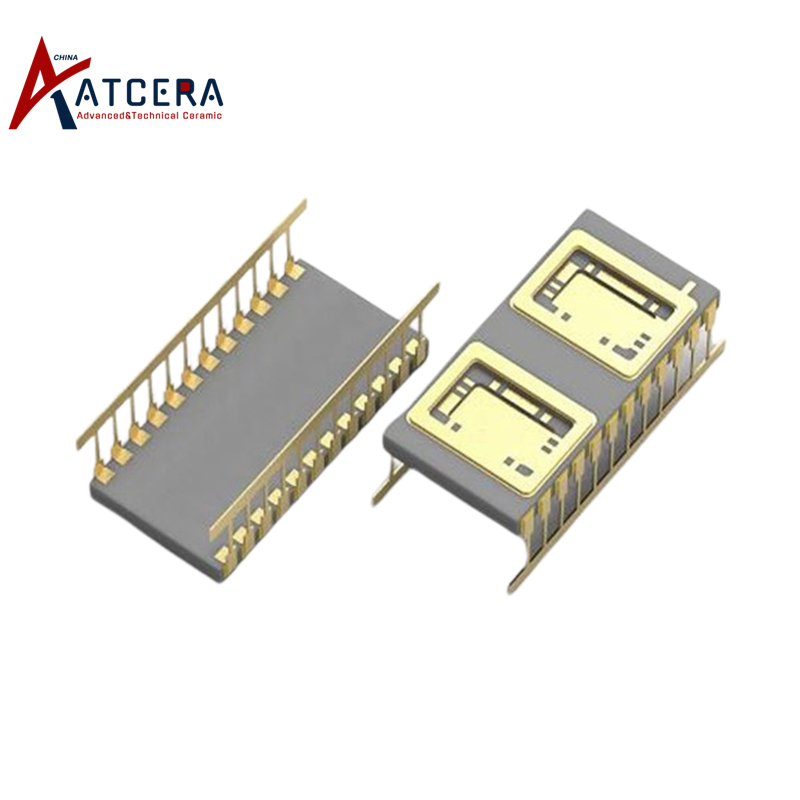

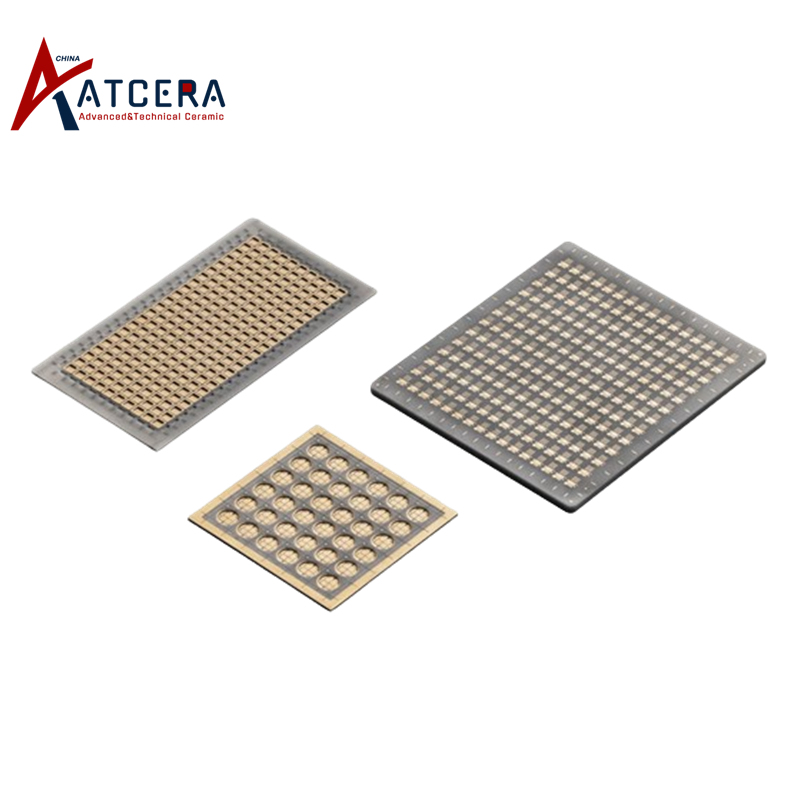

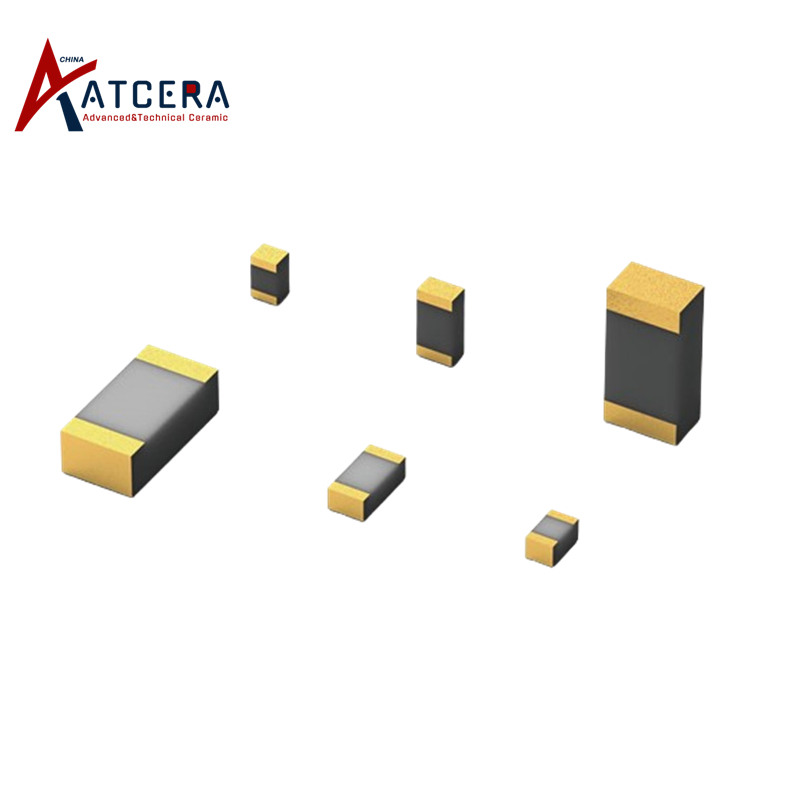

2. Electronic Components

Aluminium nitride ceramic substrate can be used to manufacture a variety of high-power and high-performance electronic components, such as power semiconductor devices, microwave devices, sensors, radio frequency modules, etc., to achieve more stable working conditions and higher performance indicators.

3. Photoelectric Devices

AlN ceramic substrate can be used in the manufacture of optoelectronic parts, including laser diodes, solar cells, photodetectors, optical communication devices, etc.

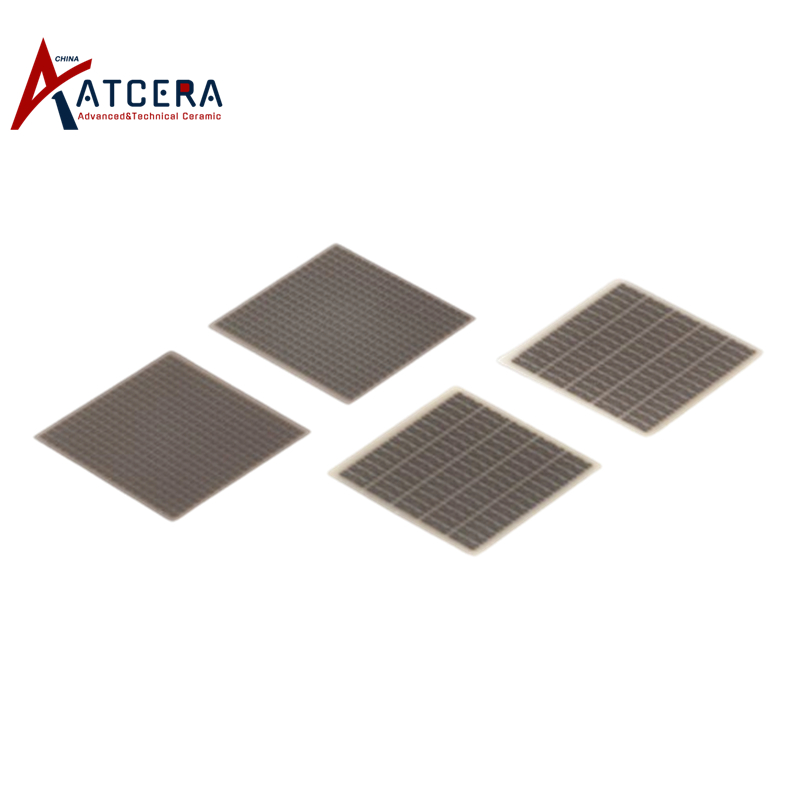

4. Thermal Management Devices

Aluminum nitride ceramic substrates can also be used to manufacture various types of thermal management devices, such as heat sink, cold plate, etc., to effectively control the temperature of electronic components and optoelectronic devices, thereby improving their reliability and life time.