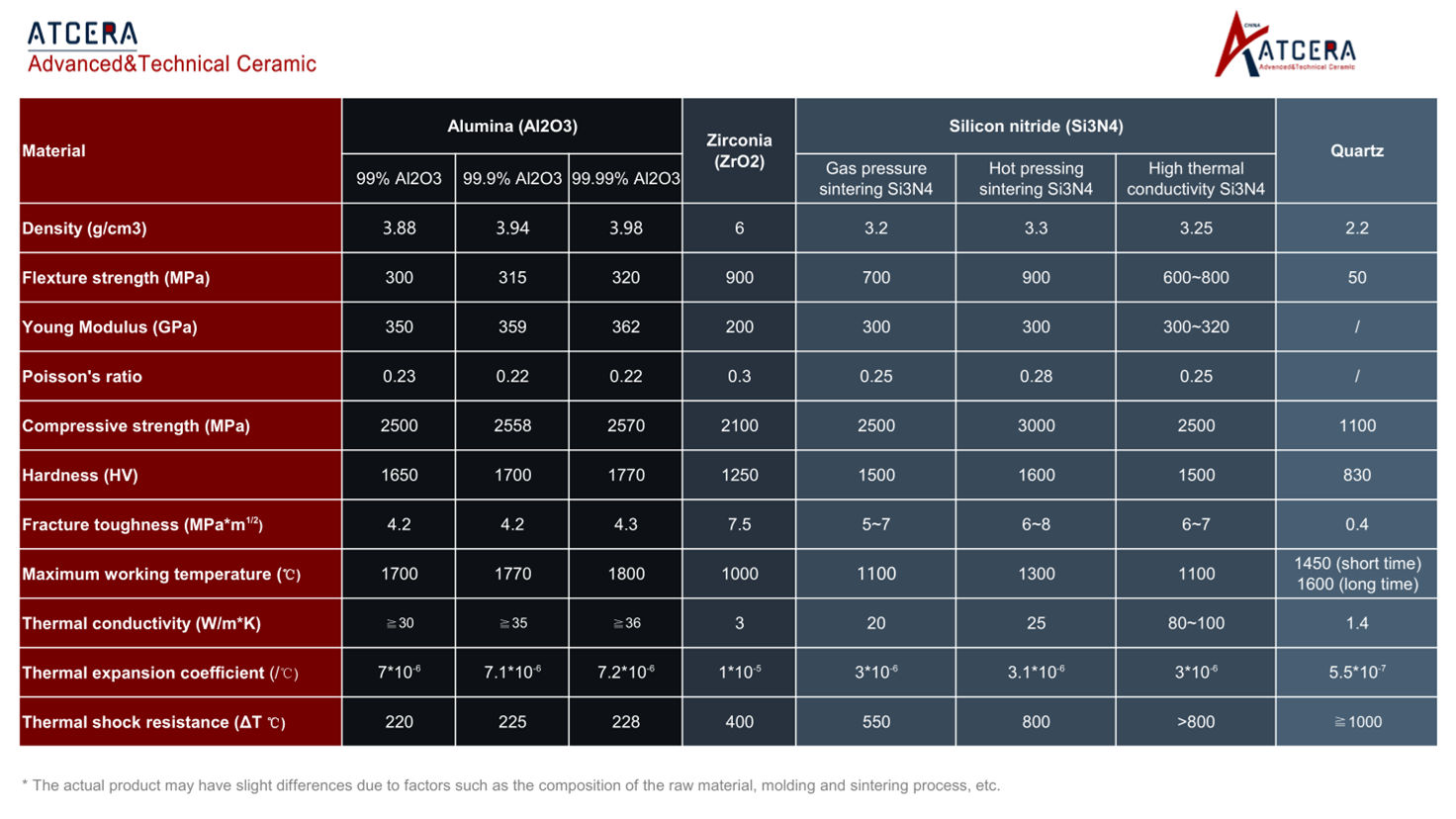

1. Laboratory analysis

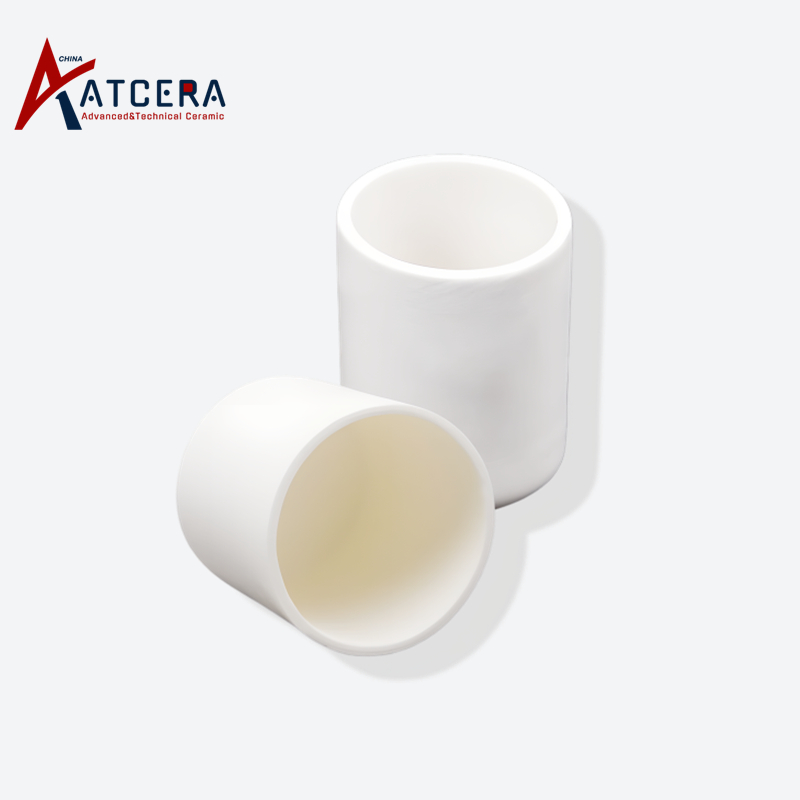

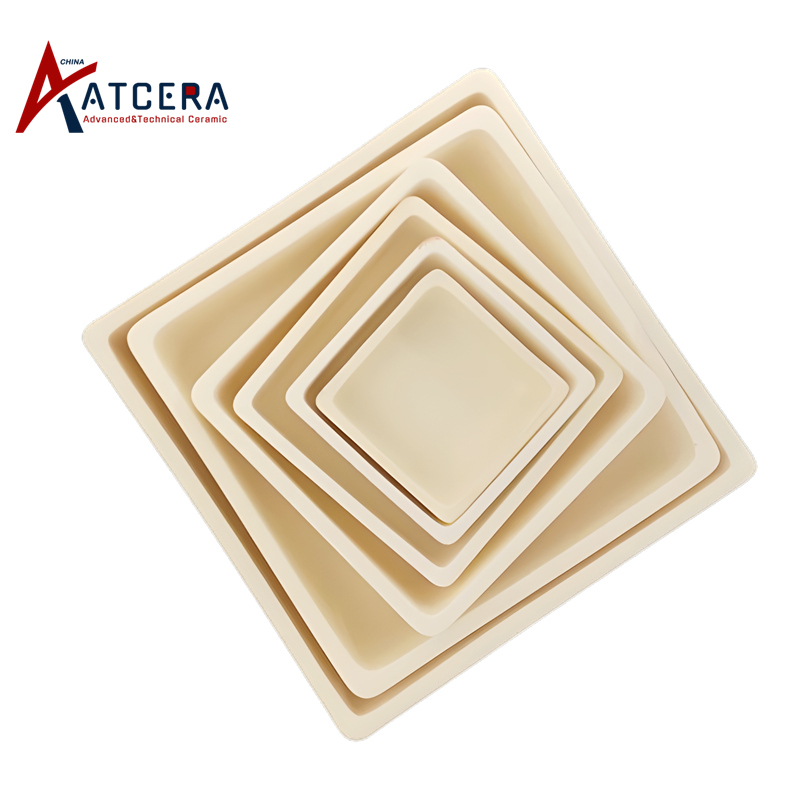

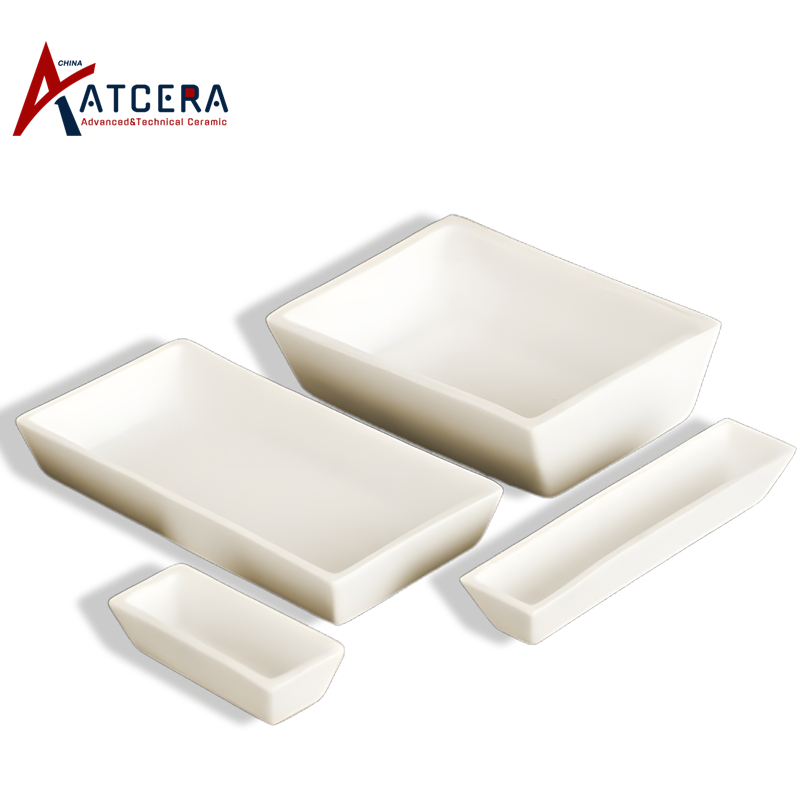

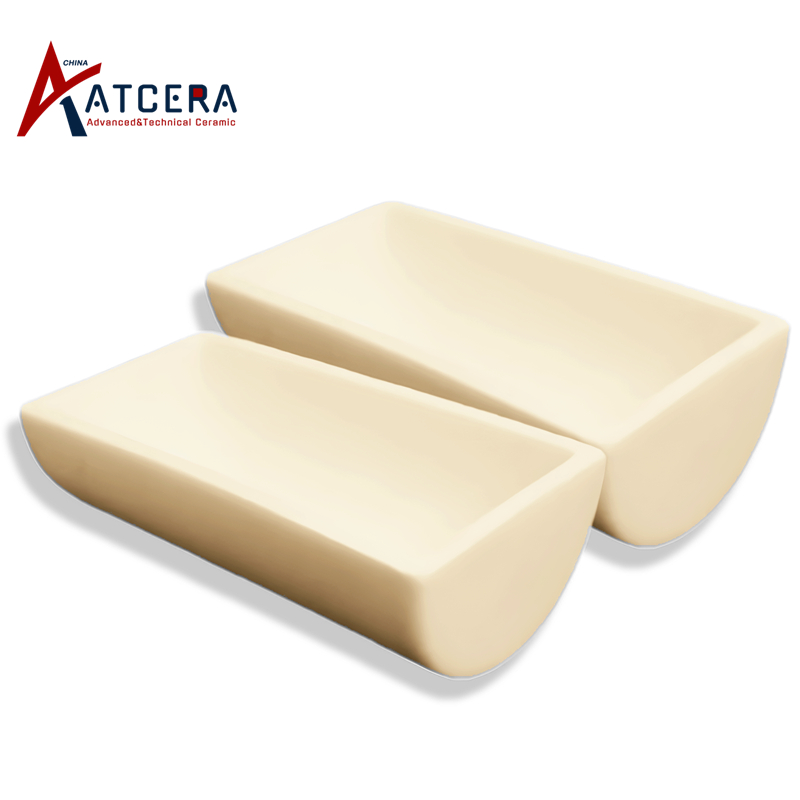

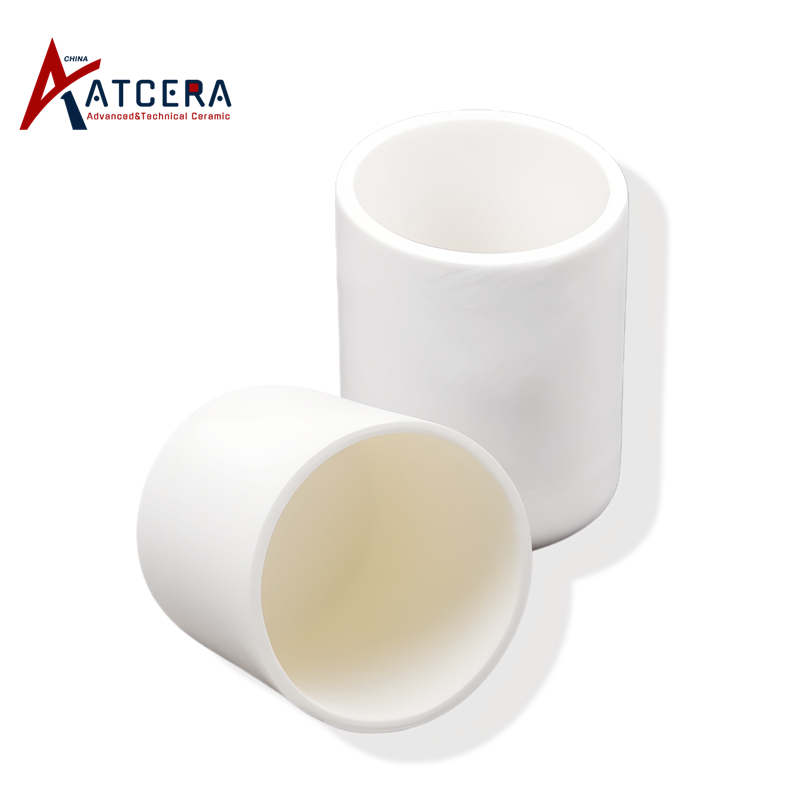

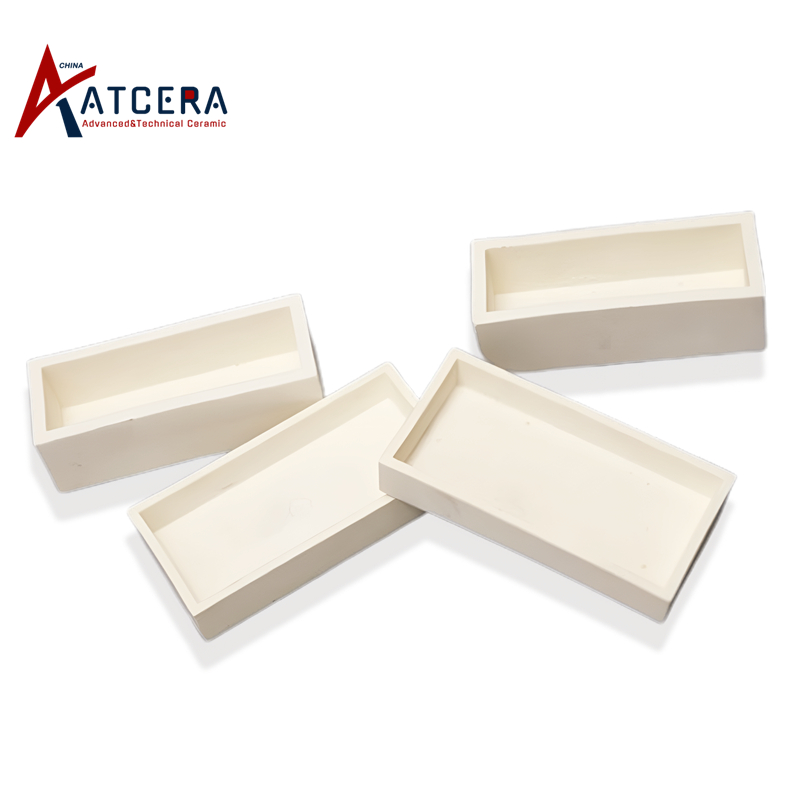

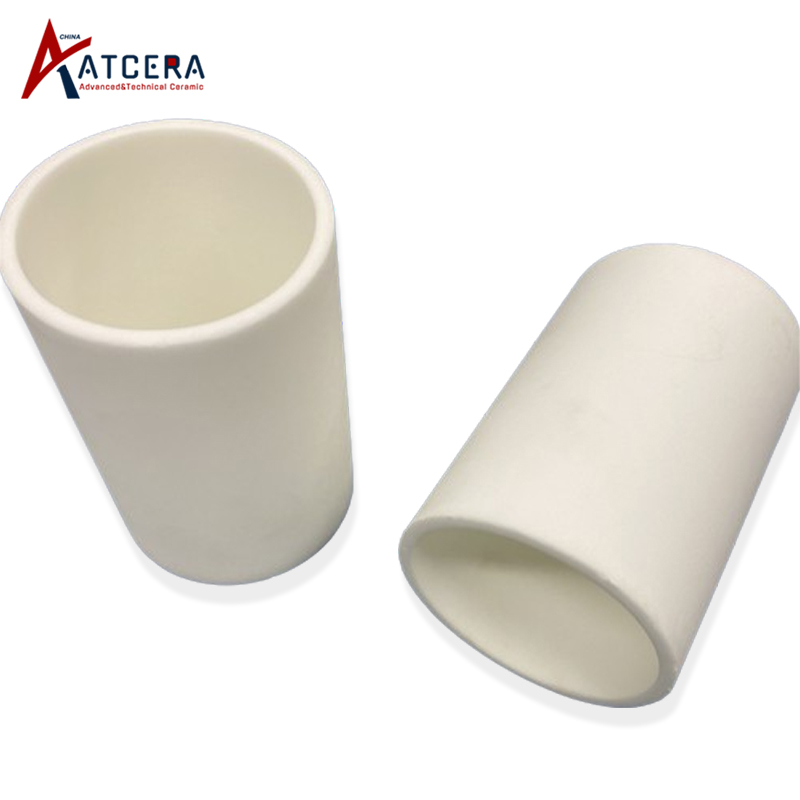

Alumina, zirconia, silicon nitride and quartz crucibles can be used to heat and melt a variety of materials for thermal analysis experiments, including metal, non-metal and ceramic materials. By observing the changes and behaviors of materials at high temperature, their physical and chemical properties can be studied and identified.

2. Industrial analysis

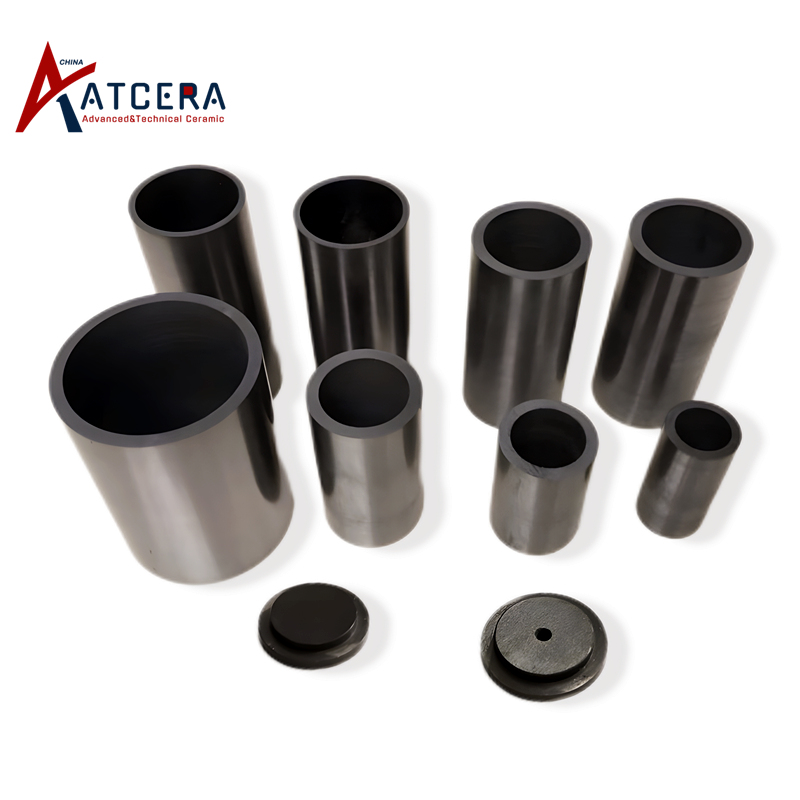

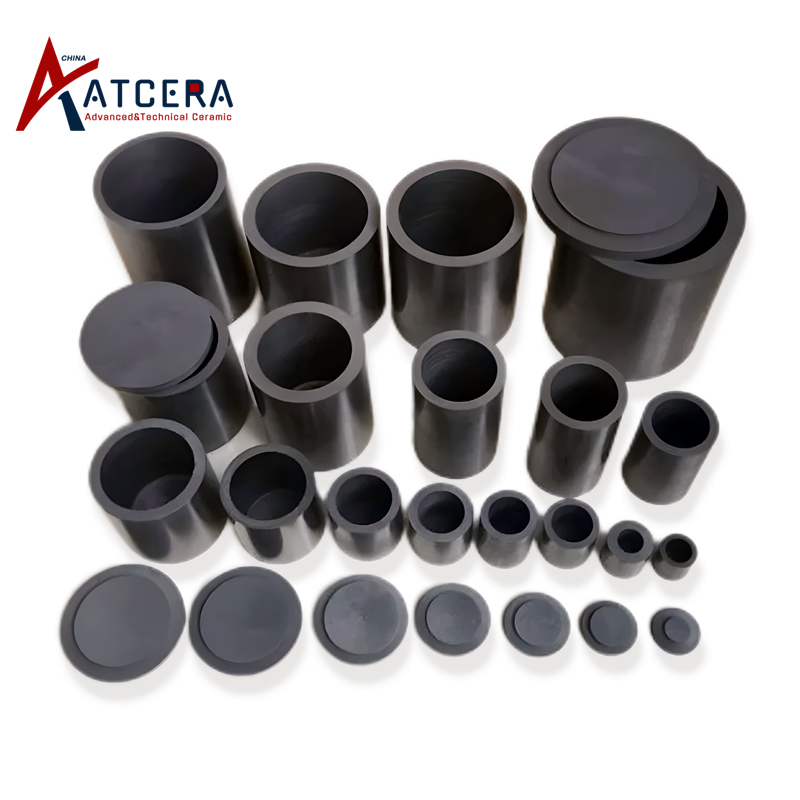

Alumina, zirconia and silicon nitride crucible can be used to analyze and test raw materials, intermediate products and final products, through high temperature analysis, the user can better understand features and characteristics of the product, so as to optimize the production process and improve product quality.

3. Material melting preparation

Alumina, zirconia and silicon nitride crucible can be used to melt a variety of high-performance materials, such as metal alloys, ceramics, glass, etc. By controlling the composition of the material and heating process, materials with excellent properties can be obtained.

4. Photovoltaic cells and semiconductor production

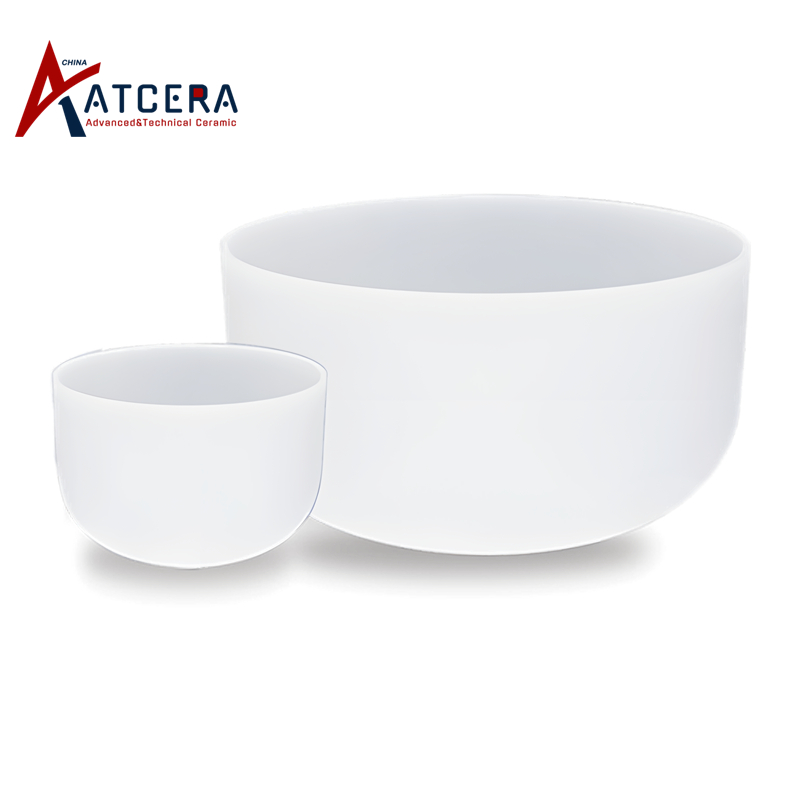

Quartz crucible can be used in the semiconductor and photovoltaic industry of monocrystalline silicon growth process, it is available for continuous crystal pulling under high temperature condition.