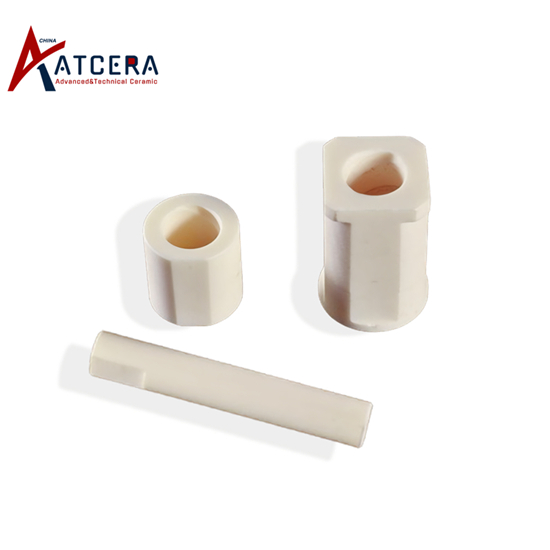

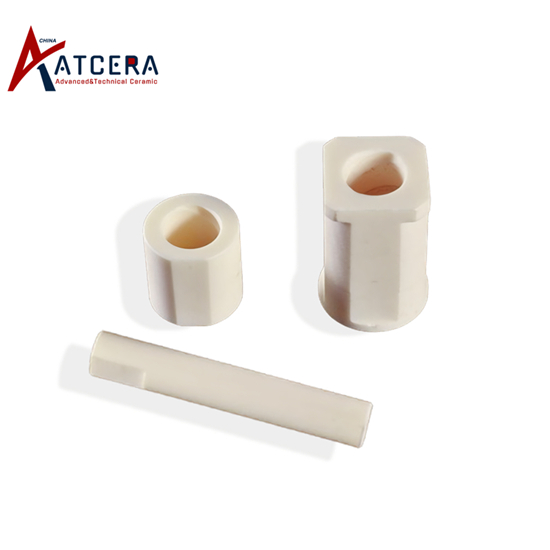

In the realm of advanced engineering materials, ceramic shaft sleeves have emerged as a game-changer, particularly in the European and American markets. These precision-engineered components, made from high-purity alumina, offer unparalleled wear resistance, compression strength, and thermal stability—all crucial factors in today's demanding industrial environments.

Characteristics of Ceramic Shaft Sleeves

Ceramic shaft sleeves are notable for their inherent physical properties. High-purity alumina, the primary constituent, guarantees superior durability and resilience. The sleeves are designed to provide steadfast support to shafts, minimizing wear and tear while significantly reducing friction between the shaft and the bearing. This, in turn, leads to decreased operational resistance, enhancing the overall efficiency of the system.

Application Fields of Ceramic Shaft Sleeves

The versatility of ceramic shaft sleeves has led to their widespread adoption across various industries. From automotive and aerospace to energy and petrochemical, these sleeves are instrumental in improving the performance and reliability of critical components. Their ability to withstand extreme temperatures and resist corrosion makes them ideal for applications where traditional materials falter.

How to Select the Right Ceramic Shaft Sleeve for Your Project

Choosing the appropriate ceramic shaft sleeve for a specific application is crucial. Factors such as the operating environment, temperature range, and load requirements must be carefully considered. A thorough understanding of the material properties and how they align with the project's requirements is essential to ensure optimal performance and longevity.

Manufacturing Process of Ceramic Shaft Sleeves

The manufacturing process of ceramic shaft sleeves involves precision engineering and stringent quality control measures. High-purity alumina powder is processed using advanced techniques to ensure uniformity and consistency. The resulting sleeves are then subjected to rigorous testing to ensure they meet or exceed industry standards.

Case Studies and Success Stories of Using Ceramic Shaft Sleeves

Numerous case studies and success stories highlight the transformative impact of ceramic shaft sleeves. From improving the efficiency of energy-intensive processes to enhancing the reliability of critical machinery, these components have proven their worth in real-world applications. One such example is in the automotive industry, where ceramic shaft sleeves have significantly reduced maintenance costs and downtime.

Future Prospects and Innovations in Ceramic Shaft Sleeves

As technology continues to evolve, so do the possibilities for ceramic shaft sleeves. Ongoing research and development are focused on enhancing the material's properties and exploring new applications. Advances in manufacturing techniques and material science are expected to further increase the performance and durability of these crucial components.

Conclusion

Ceramic shaft sleeves represent a significant leap forward in the realm of advanced engineering materials. Their unique properties and versatility have made them indispensable in various industries, especially in Europe and America. As these components continue to evolve, their impact on industrial efficiency and reliability will only grow.