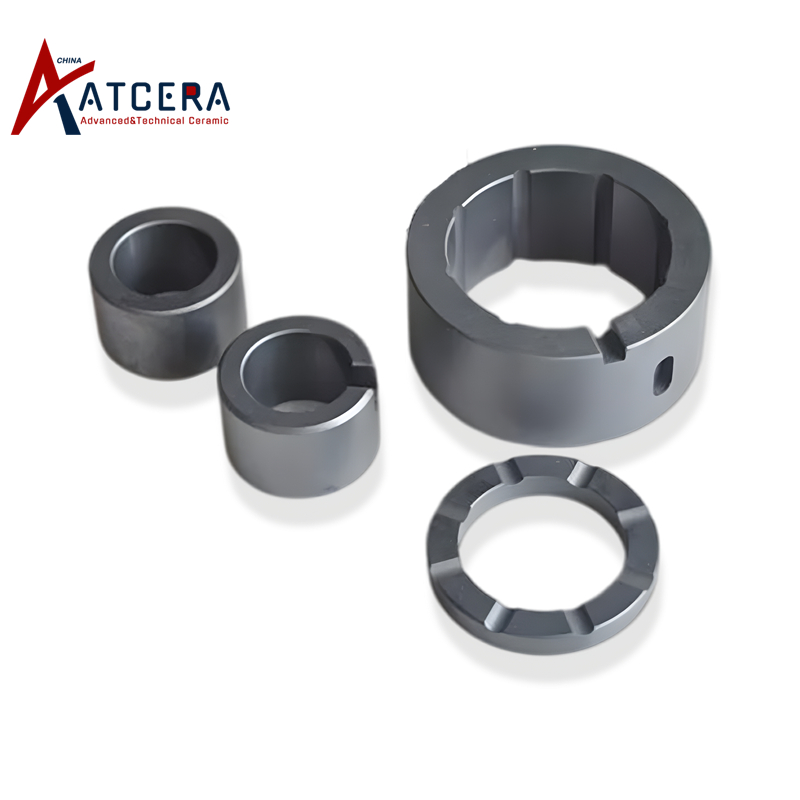

1. Chemical equipment

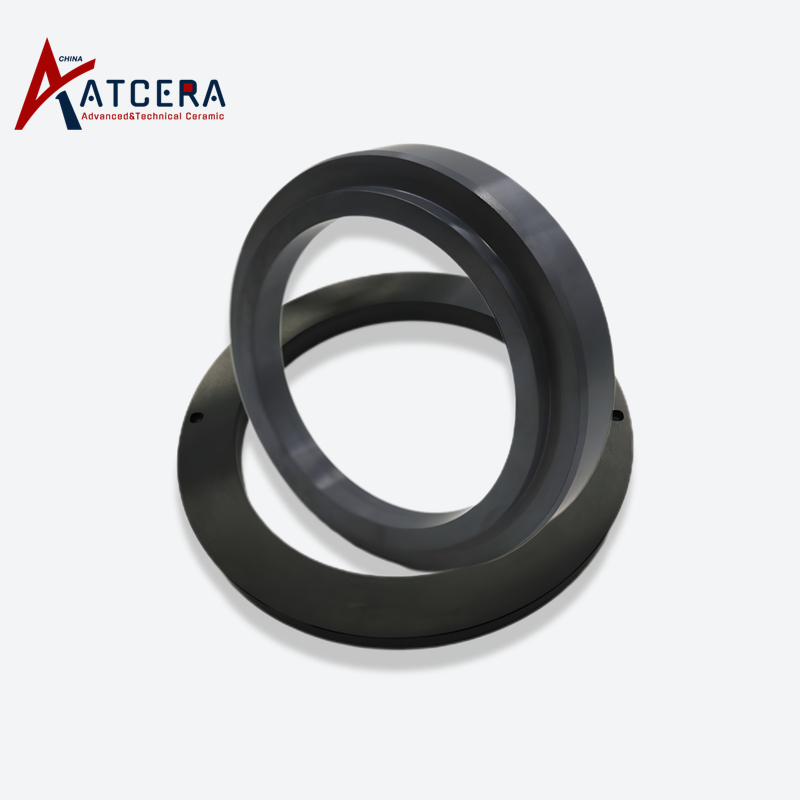

Silicon carbide and silicon nitride seal rings have good corrosion resistance, performance is not affected by acid, alkali and other chemicals, can be used in a variety of chemical equipment.

2. Mining and engineering machinery

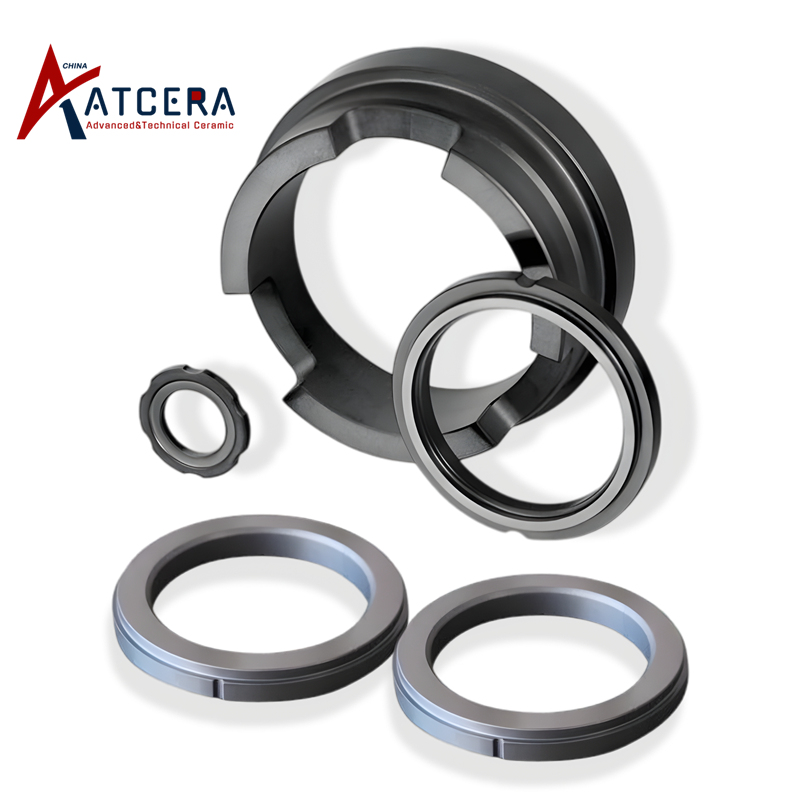

Silicon carbide sealing rings and silicon nitride sealing rings material high hardness, good wear resistance, and high compressive strength, can be used for high load, high dust environment, replacement cycle is long.

3. Metal smelting furnace and other high temperature equipment

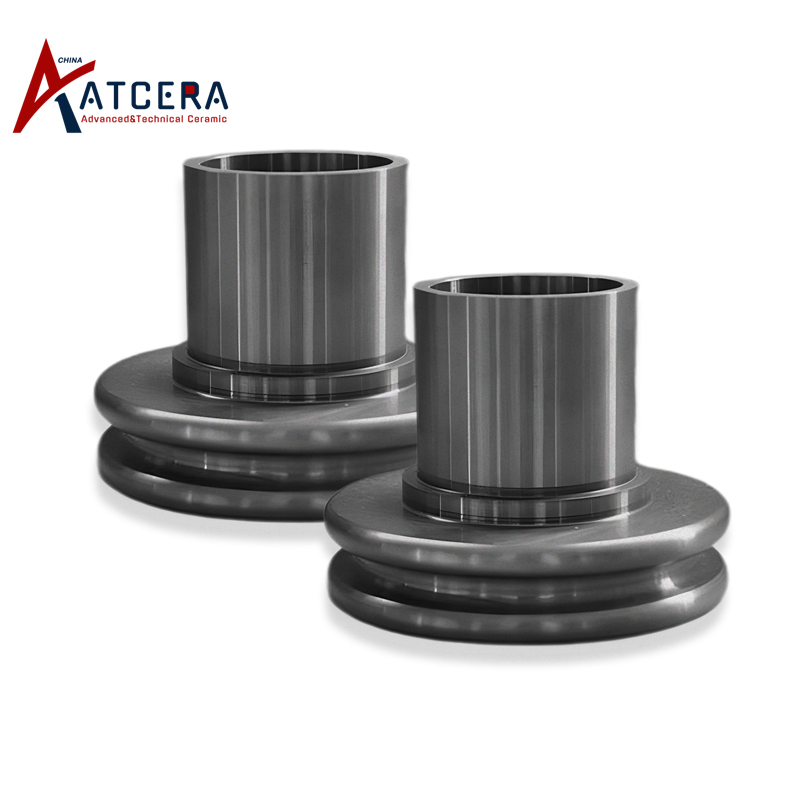

Silicon carbide and silicon nitride sealing rings have good high temperature resistance, thermal expansion is small and thermal stress to equipment is small, which can effectively ensure the reliability of the equipment.

4. Semiconductor and photovoltaic cell manufacturing

Silicon nitride insulation rings are one of the key components in polysilicon reduction furnaces, which is used in photovoltaic cells and semiconductor production process.