1. Food Industry

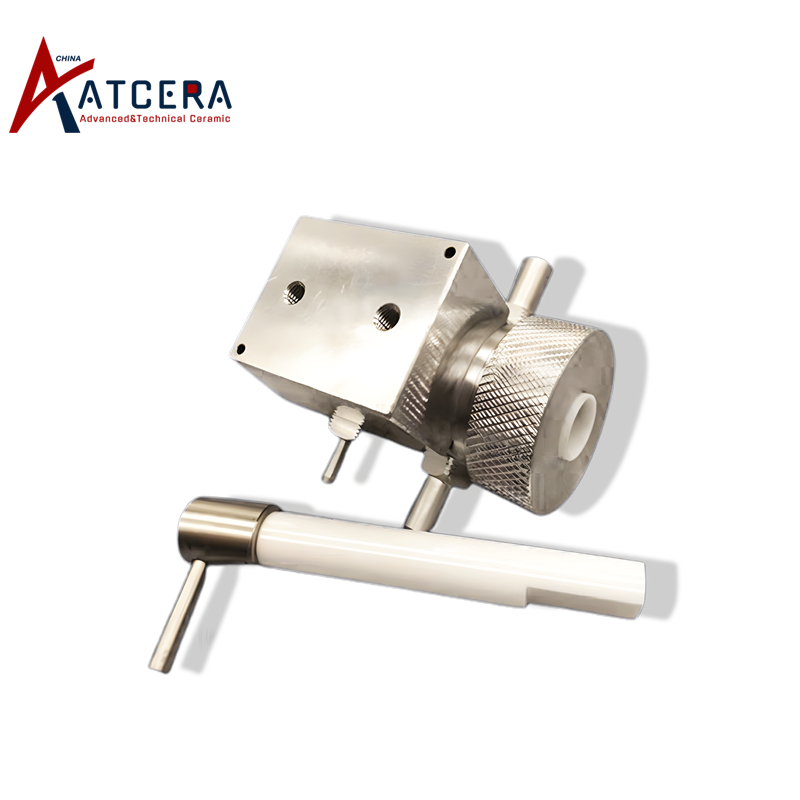

Used for beverage, dairy products, spices and other liquids quantitative filling, filling accuracy is high, meanwhile without any influence to the quality and taste. Alumina ceramic metering pumps can be used to control the amount of food additives added to maintain the quality and taste of food.

2. Pharmaceutical Industry

Alumina material biocompatibility is good, alumina filling pump can be used for the filling and measurement of various liquid pharmaceutical and biological agents, to meet the high requirements for drug safety and stability in biomedicine field.

3. Cosmetics industry

Used in perfume, lotion and other liquid cosmetics filling, to achieve high precision and high efficiency;

4. Chemical Industry

Aluminum oxide material is chemically inert and has good corrosion resistance, and can be used for precision filling of various chemical liquids, such as chemical agents, battery electrolytes, etc.. Aluminum oxide material is chemically inert and has good corrosion resistance, and can be used for precision filling of various chemical liquids, such as chemical agents, battery electrolytes, etc.