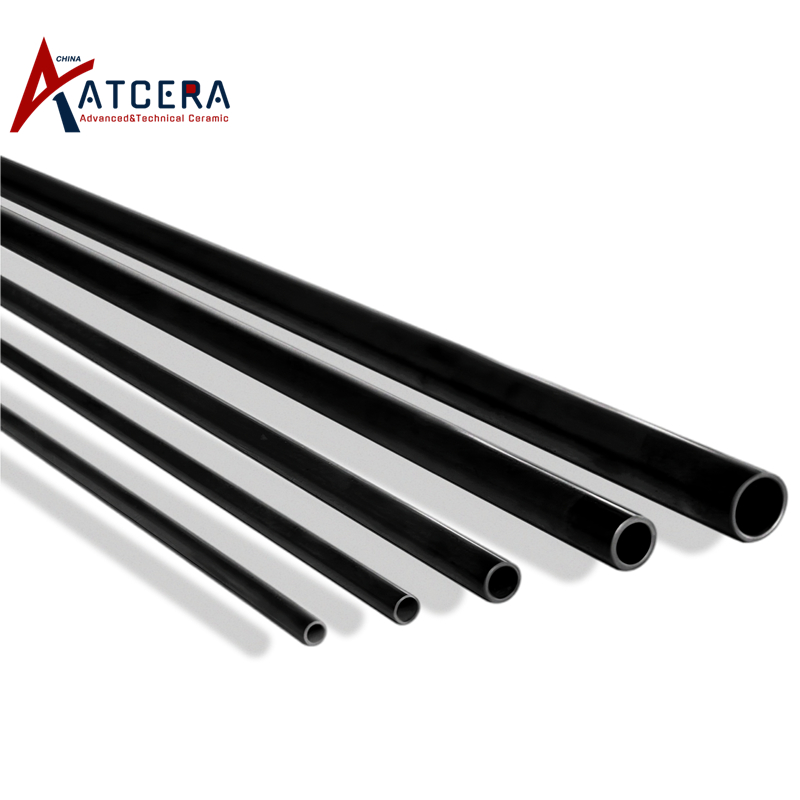

1. Ceramic pipe system components

Alumina, zirconia, silicon carbide and silicon nitride have good corrosion resistance and mechanical strength, they can be used to produce pipe system components, including pipe, pump, valve and sealing part.

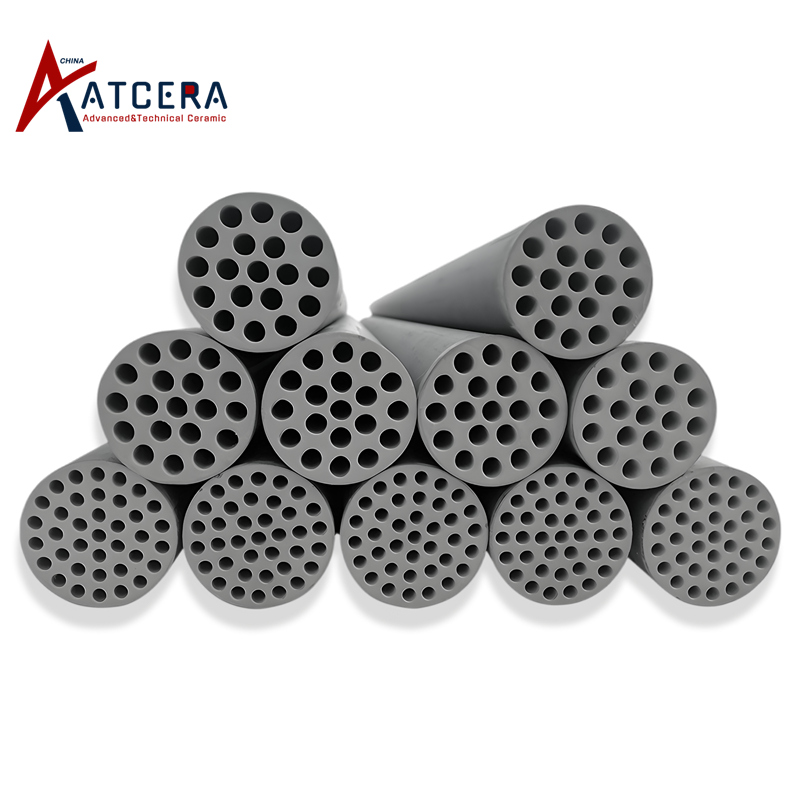

2. Ceramic membrane tube

Alumina, zirconia and silicon carbide ceramics have good corrosion resistance, high temperature resistance, non-toxic, harmless and pollution-free, they can be used to produce membrane tube for filtration purpose, to separate particles from liquid.

3. Crucible and cuvette

Alumina, zirconia, silicon nitride and quartz have high temperature resistance and good thermal shock resistance, also resistant to acid and alkali corrosion, they can be used to produce crucbile for various chemical material analysis. In addition, quartz can be used to produce cuvette for spectral analysis.

4. Ceramic electrical heater

Alumina and silicon nitride ceramics have high temperature resistance, good thermal shock resistance and corrosion resistance, they can be used to produce electrical heater, to provide stable and continuous heating for petroleum and chemical production process.

5. Ceramic heat exchanger

Silicon carbide ceramic has high temperature and good thermal shock resistance, also with good corrosion resistance, it can be used to produce heat exchanger for petroleum and chemical production process.