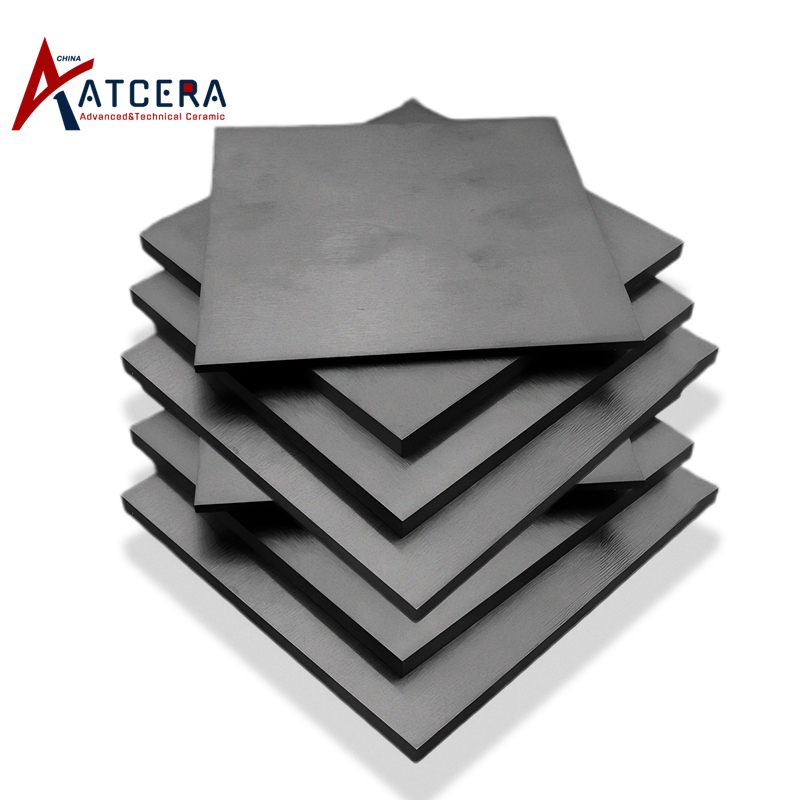

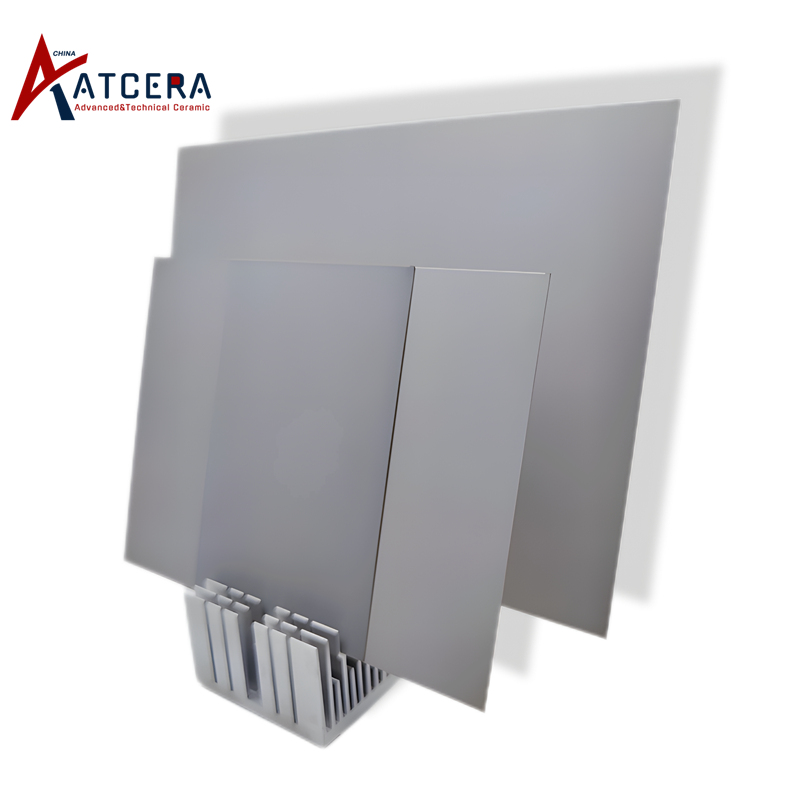

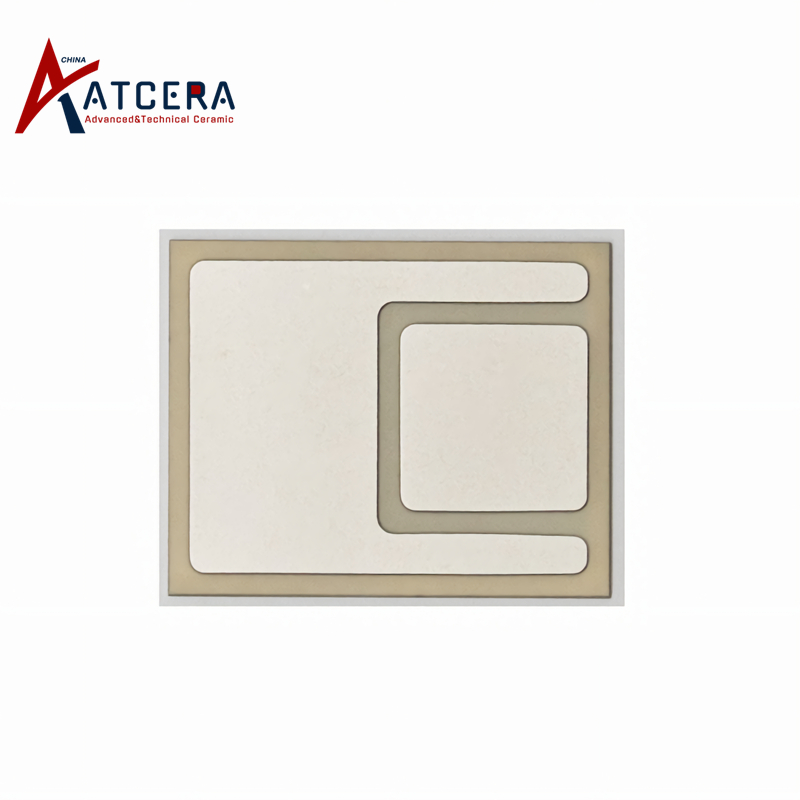

Silicon nitride ceramic substrate is mainly used in semiconductor, electronics and other microelectronics device manufacturing, as the substrate of chips and electronic components, including integrated circuit (IC), radio frequency (RF) devices, piezoelectric components, photoelectric components, sensors, MEMS and other micro electronic devices. As a high-performance material, silicon nitride ceramic substrate can provide a stable support platform to ensure normal operation and performance of the components.

1. Electronic Industry Applications

Silicon nitride ceramic substrate has high insulation performance and excellent high temperature resistance, can meet the high reliability and high performance requirements of electronic components, mainly used in the manufacture of electronic components, such as electronic capacitors, resistors, magnetic components and so on. In addition, it can also be used to manufacture the medium layer of high-speed communication equipment to ensure the stable transmission of high-frequency signals.

2. Photoelectric Industry

Silicon nitride ceramic substrates can provide good thermal performance and mechanical strength, and are widely used in the photoelectric industry, especially in the manufacture of high-power leds, ensuring the stability and life of LED components. In addition, it can also be used to manufacture support materials for solar panels to enhance their mechanical strength and chemical resistance.

3. Electrical Industry

Silicon nitride ceramic substrate has excellent insulation performance and good heat dissipation, and can be used to manufacture various high-power electrical components, such as power modules, heating modules, etc., effectively ensuring the service life and reliability of electrical equipment.