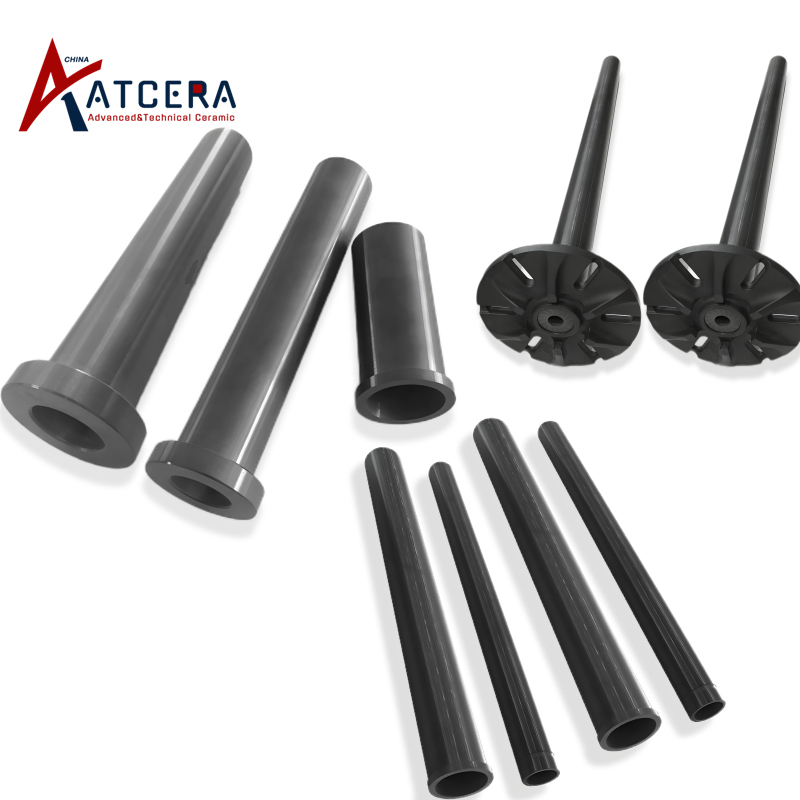

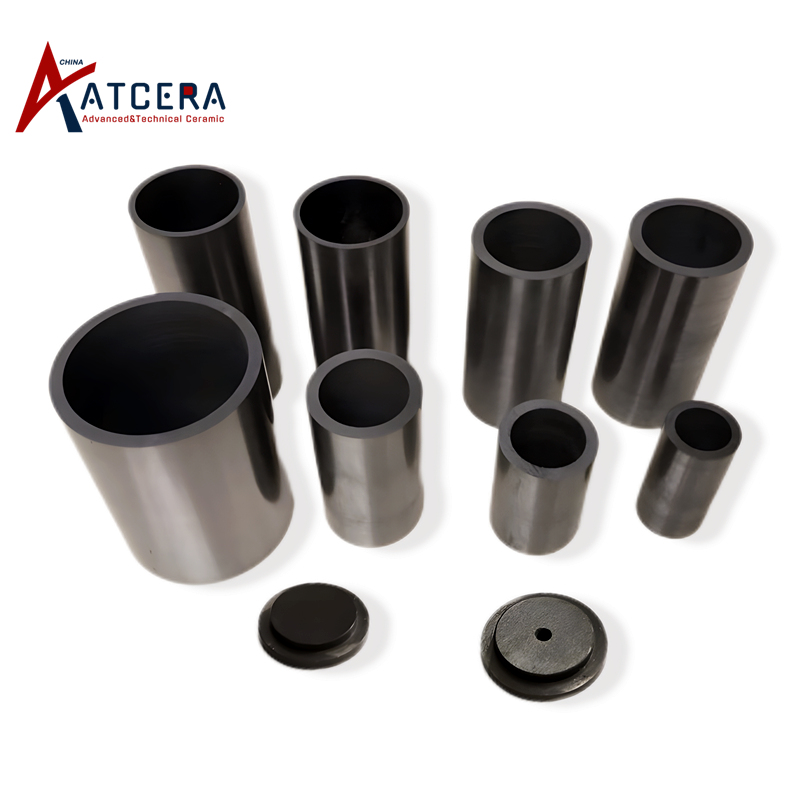

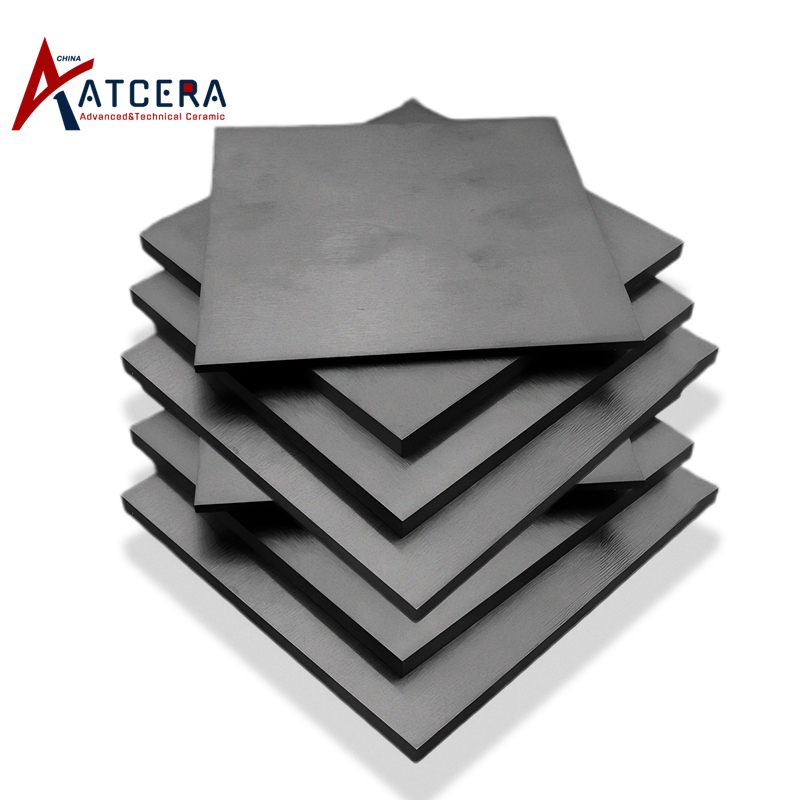

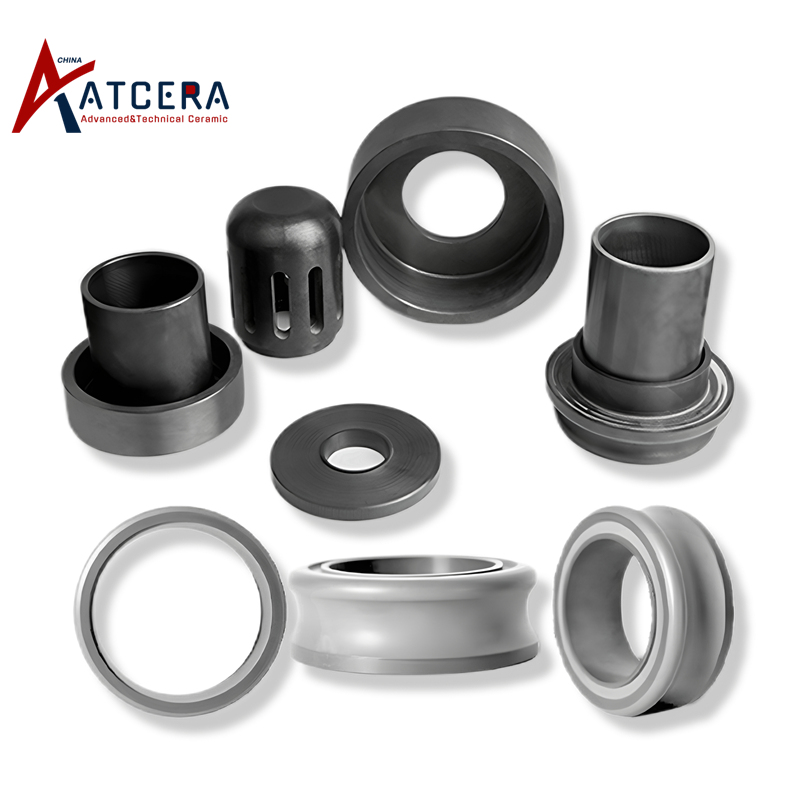

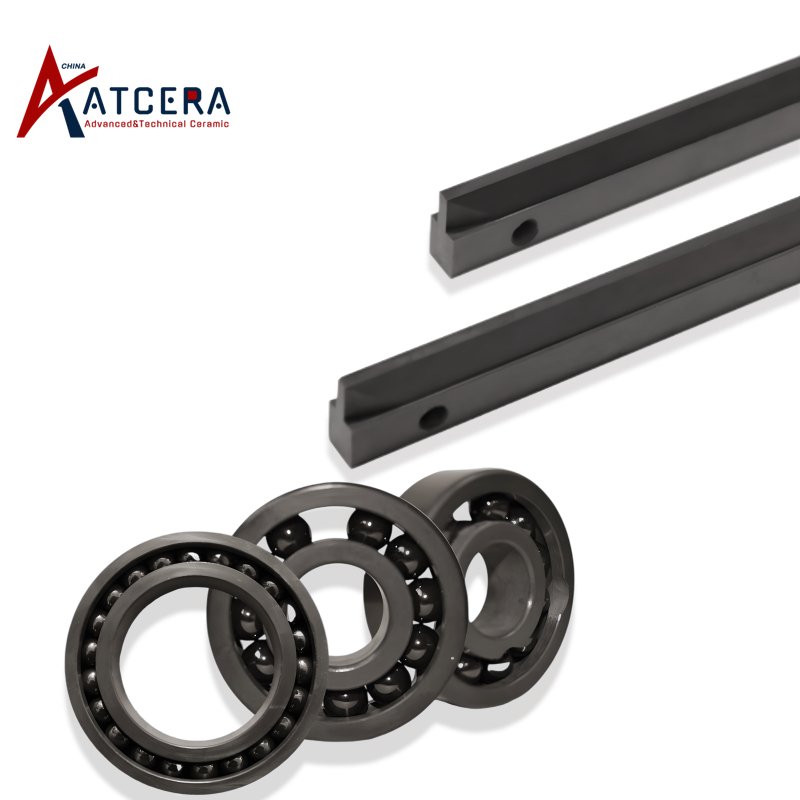

Silicon nitride ceramic is made of silicon nitride powder as the main raw material, after forming and sintering to obtain a stable crystalline phase structure, it has the characteristics of high strength, high temperature resistance, high hardness, good wear resistance, good corrosion resistance, light weight, good thermal shock resistance and oxidation resistance, it is widely used in mechanical engineering , semiconductor , petrochemical , electric power, environmental protection and energy saving industries. According to the composition and sintering process, its main types are reactive bonded sintered silicon nitride, atmospheric pressure sintered silicon nitride, hot pressure silicon nitride, etc., appropriate type can be selected according to application scenario and parameter requirements.

| view all silicon nitirde ceramic products |