1. Ceramic grinding ball and bead

Alumina, zirconia and silicon nitride ceramics have high hardness and mechanical strength, they can be used to produce grinding ball and bead for various grinding equipment, to grind ore and chemical raw material into fine powder for further process.

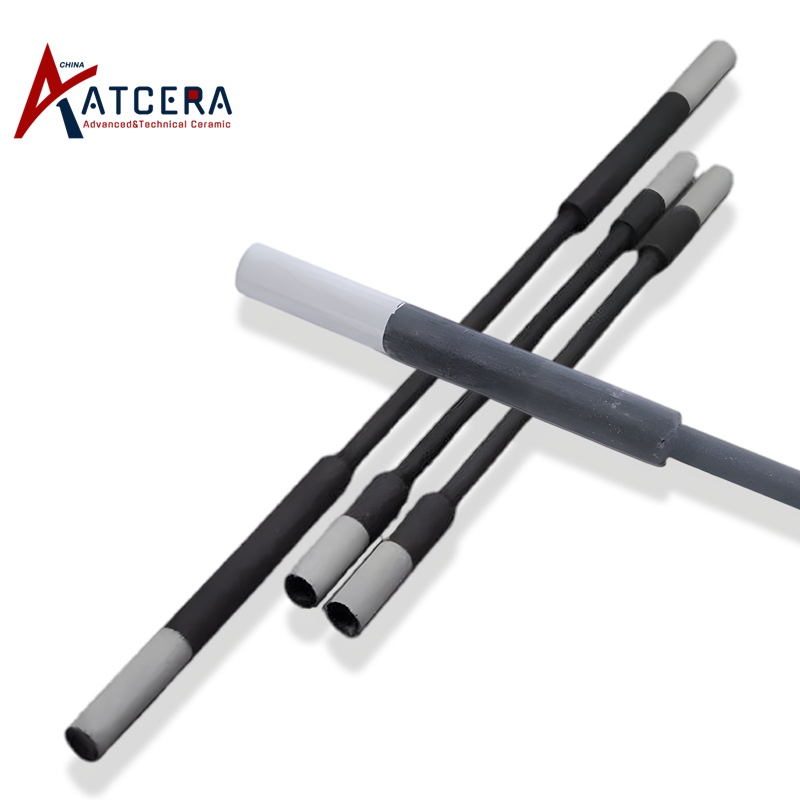

2. Ceramic heater

Silicon carbide ans alumina ceramics have high temperature and good thermal shock resistance, also with high thermal conductivity and good corrosion resistance, it can be used to produce heat exchanger for metallurgical industry in the smelting process.

3. Ceramic heat exchanger

Silicon carbide ceramic has high temperature and good thermal shock resistance, also with good corrosion and wear resistance, it can be used to produce heat exchanger in metallurgical industry.

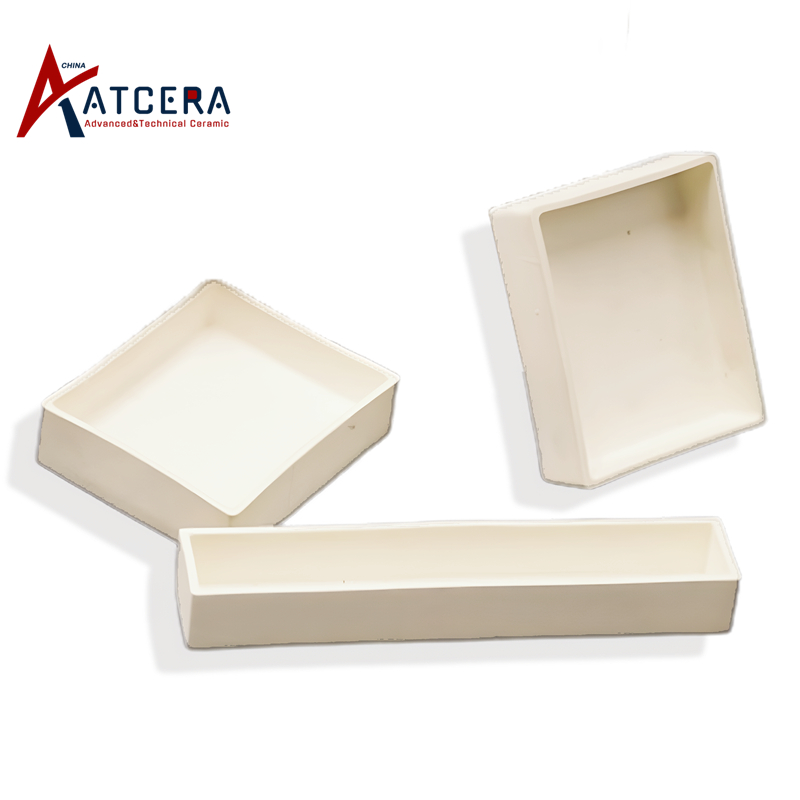

4. Crucible

Alumina, zirconia and silicon nitride have high temperature resistance and good thermal shock resistance, also resistant to acid and alkali corrosion, they can be used to produce crucbile for various metal product material analysis.