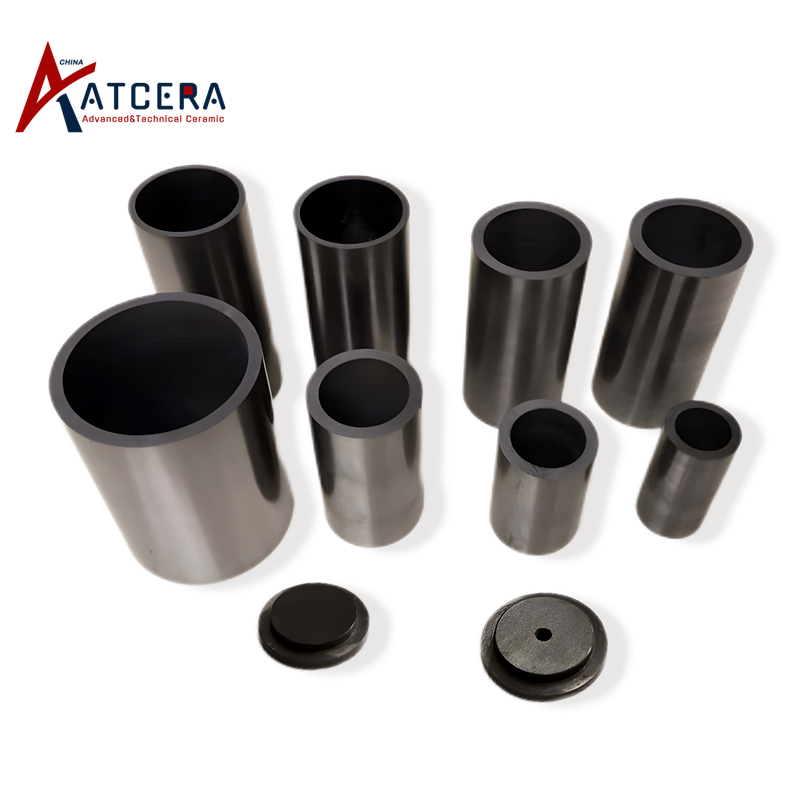

The silicon carbide crucible boasts an array of remarkable properties such as high temperature resistance, excellent thermal shock stability, minimal expansion coefficient, resilience against strong acids and alkalis, resistance to spalling, good anti-powdering characteristics, and superior high-temperature creep resistance. Furthermore, its rapid heat conduction ensures uniform heating of the products being fired, effectively reducing energy consumption, accelerating the firing process, and enhancing production output. This crucible finds widespread application in the sintering of lithium-ion battery materials, electronic components, magnetic materials, highly corrosive substances, and various ceramic powders.

| view all silicon carbide crucibles |