1. Ceramic pump

Alumina and zirconia have high hardness, wear resistance is good, also with good corrosion resistance and biological compatibility, they can be used to produce pump for filling, metering, pressurizing, and circulation of various liquids.

2. Ceramic bearing

Zirconia, silicon nitride, silicon carbide and alumina ceramics have high temperature resistance, good wear and corrosion resistance, also with light weight and self-lubrication, they can be used to produce bearings for harsh working environment and high speed occasions.

3. Ceramic valve

Alumina, zirconia, silicon nitride and silicon carbide ceramics have high temperature resistance, good wear and corrosion resistance, also with good biological compatibility, they can be used to produce valve for machinery equipment, petrochemical, pharmaceutical and biological, food processing, power plants, water supply, metal smelting, etc.

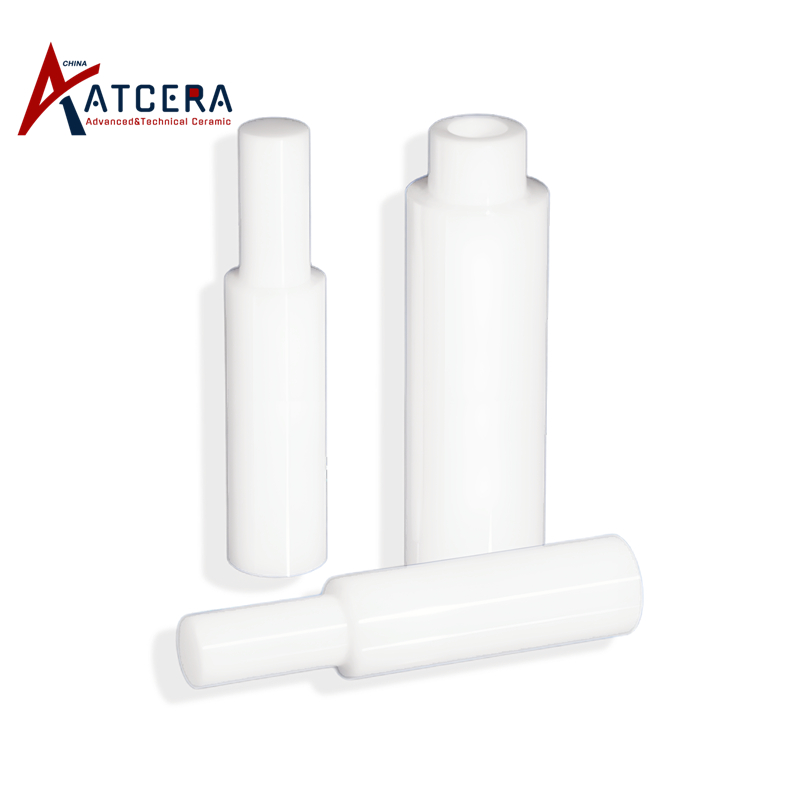

4. Ceramic plunger

Alumina, zirconia, silicon nitride and silicon carbide ceramics have high temperature resistance, good wear and corrosion resistance, also with good biological compatibility and self-lubrication, they can be used to produce plunger for plunger pumps, syringes, pneumatic and hydraulic system components.

5. Silicon nitride machining cutting tool

Silicon nitride ceramic has high hardness, good wear resistance, and excellent thermal stability, corrosion resistance and high temperature oxidation resistance, which can be used to make machining tools for machining various high hardness materials, including cutting, milling, drilling, etc.

6. Ceramic grinding ball and bead

Alumina, zirconia and silicon nitride ceramics have high hardness and mechanical strength, they can be used to produce grinding ball and bead for various grinding equipment.