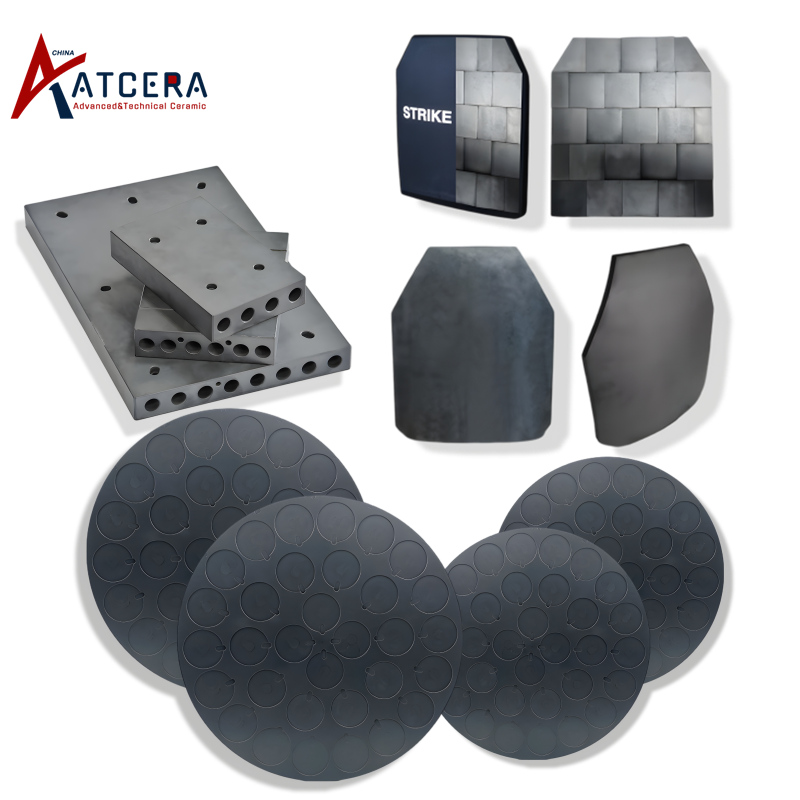

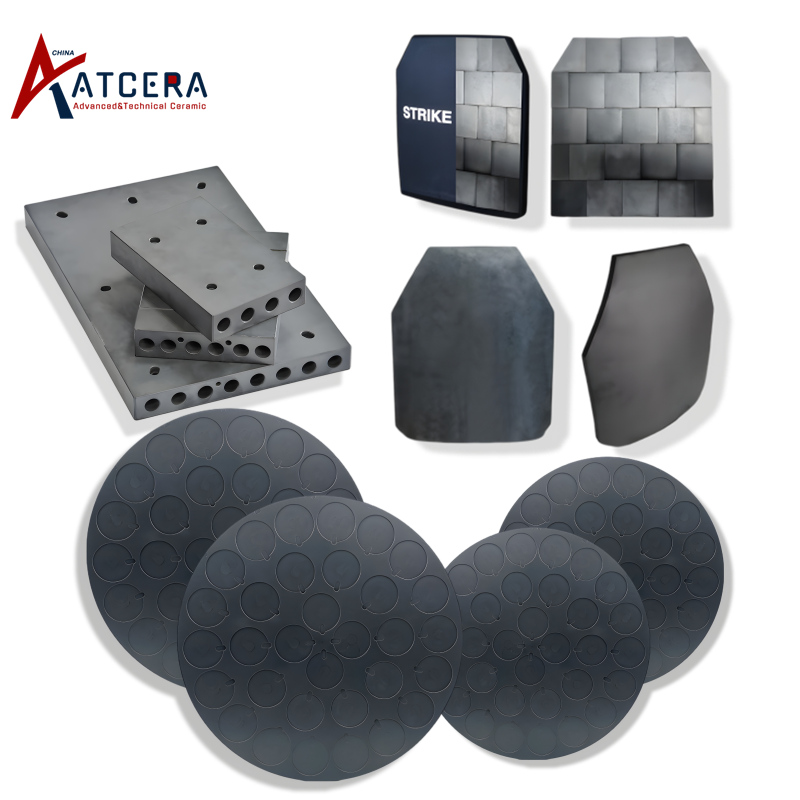

ATCERA can provide silicon carbide plates, and they can be widely used in mechanical engineering, petrochemical, high temperature refractory, metallurgy, military and other industries.

| view all silicon carbide plates |

ATCERA can provide silicon carbide plates, and they can be widely used in mechanical engineering, petrochemical, high temperature refractory, metallurgy, military and other industries.

| view all silicon carbide plates |

Silicon carbide is a kind of widely used advanced industrial ceramic, to meet the needs of different fields, raw material composition and appropriate sintering process can be selected, and required properties are achieved.

⩟ Corrosion resistance

Silicon carbide material has good corrosion resistance, it does not react with various acids, alkalis, salt or other chemical agents, without the risk of failure caused by corrosion;

⩟ High temperature resistance

The normal use temperature of the silicon carbide ceramic can reach higher than 1100℃, available for the requirements of high temperature environment;

⩟ Good wear resistance

Silicon carbide material has high hardness, which is up to 16GPa, so the wear resistance is very good and service life is long;

⩟ High strength

Strength of silicon carbide is high, flexture strength is up to 900MPa, also the fracture toughness is high, so it can be used for application with heavy load and mechanical shock;

⩟ Good thermal shock resistance

Silicon carbide has small thermal expansion, and high termal conductivity, thermal shock resistance is very good, up to 800℃.

| Item | Unit | Index Data | |||

| Reaction-sintered SiC (SiSiC) |

Silicon Nitride Bonded With SiC (NBSiC) |

Sintered SiCn Without Pressure (SSiC) |

|||

| SiC Content | % | 85 | 80 | 99 | |

| Free Silicon Content | % | 15 | 0 | 0 | |

| Max. Service Temp. | ℃ | 1380 | 1550 | 1600 | |

| Density | g/cm3 | 3.02 | 2.72 | 3.1 | |

| Porosity | % | 0 | 12 | 0 | |

| Bending Strength | 20℃ | Mpa | 250 | 160 | 380 |

| 1200℃ | Mpa | 280 | 180 | 400 | |

| Modulus of Elasticity | 20℃ | Gpa | 330 | 220 | 420 |

| 1200℃ | Gpa | 300 | / | / | |

| Thermal Conductivity | 1200℃ | W/m.k | 45 | 15 | 74 |

| Coefficient of Thermal Expansion | K-1×10-6 | 4.5 | 5 | 4.1 | |

| Vickers Hardness | HV | kg/mm2 | 2500 | 2500 | 2800 |

*This chart illustrates the standard characteristics of the silicon carbide materials commonly employed in the manufacturing of our SiC products and parts. Please be aware that the attributes of customized silicon carbide products and parts may vary depending on the specific processes involved.

1. Chemical and metallurgical industries

Silicon carbide plates have very good corrosion resistance, good chemical inertia, and do not react with various chemical media, also with excellent high temperature resistance, they are suitable for manufacturing a variety of chemical and metallurgical equipment, such as reaction vessel, heating plate, etc.

2. Military industry

Silicon carbide plates have high hardness and low density, they can be used to produce body armor liner, as well as protective device for bulletproof vehicle and tank.

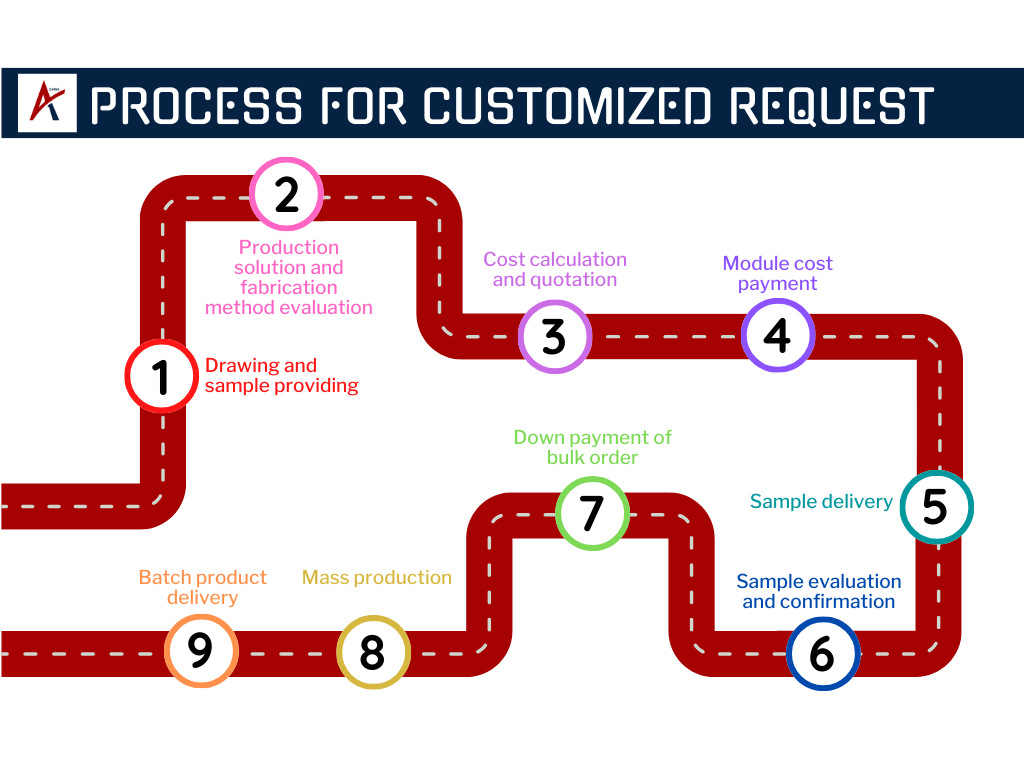

Process for Customized Request

⩟ Drawing and sample providing

⩟ Production solution and fabrication method evaluation

⩟ Cost calculation and quotation

⩟ Module cost payment

⩟ Sample delivery

⩟ Sample evaluation and confirmation

⩟ Down payment of bulk order

⩟ Mass production

⩟ Batch product delivery

Extensive Supplier Expertise

Extensive Supplier Expertise

Over 20 years experience in the field of advanced industrial ceramics, ATCERA is able to provide professional technical support and the most optimized solution.

Sophisticated Production Infrastructure

Sophisticated Production Infrastructure

Advanced processing equipment, and strict quality control system.

Assured Batch Supply

Assured Batch Supply

Stable production capacity and supply chain, batch delivery cab be well guaranteed.

Cost-Effective Excellence

Cost-Effective Excellence

High cost performance, and perfect after-sales service.

Although our primary focus is on advanced ceramic materials such as alumina, zirconia, silicon carbide, silicon nitride, aluminum nitride, and quartz ceramics, we are always exploring new materials and technologies. If you have a specific material requirement, please contact us, and we will do our best to fulfill your needs or find suitable partners.

Absolutely. Our technical team possesses profound knowledge of ceramic materials and extensive experience in product design. We are happy to provide you with material selection advice and product design support to ensure optimal performance for your products.

We do not have a fixed minimum order value requirement. We always focus on meeting our customers' needs, and we strive to provide quality service and products regardless of the order size.

In addition to ceramic products, we also provide a range of additional services, including but not limited to: customized ceramic processing services based on your needs, using blanks or semi-finished blanks produced by yourself; if you are interested in outsourced ceramic packaging and metallization services, please contact us for further discussion. We are always committed to providing you with a one-stop solution to meet your various needs.

Yes, we do. No matter where you are located globally, we can ensure the safe and timely delivery of your order.