Are you tired of dealing with corrosion and contamination issues when melting materials in your industrial processes? Look no further. In this article, we will explore the numerous benefits of using a corrosion-resistant SiC (silicon carbide) crucible for all your melting needs.

A SiC crucible is a durable and long-lasting alternative to traditional crucibles made from other materials like graphite or clay. It offers excellent resistance to high temperatures, thermal shock, and chemicals, making it ideal for various melting applications. Whether you are melting metals, alloys, or ceramics, a SiC crucible can withstand the harsh conditions and maintain its integrity, reducing the risk of contamination and improving the quality of your final product.

In addition to its exceptional resistance properties, a SiC crucible also has excellent heat conductivity, ensuring uniform heating and reducing the chances of hot spots. This results in improved efficiency and cost savings in your melting processes.

Join us as we delve deeper into the advantages of using a corrosion-resistant SiC crucible and how it can revolutionize your melting operations.

Understanding Corrosion in Crucibles

Corrosion is a significant challenge that many industries face when it comes to melting and processing materials. Traditional crucibles, often made from materials like graphite or clay, are susceptible to corrosion, particularly when exposed to high temperatures, harsh chemicals, or aggressive molten materials.

This corrosion can lead to a host of problems, including the degradation of the crucible's structural integrity, the introduction of impurities into the molten material, and the need for frequent replacement of the crucible. Corrosion can also cause the crucible to become brittle and prone to cracking or breaking, which can disrupt the melting process and potentially create safety hazards.

Understanding the mechanisms of corrosion in crucibles is crucial for finding effective solutions. Factors such as the chemical composition of the molten material, the operating temperature, and the exposure to various reactive substances can all contribute to the rate and severity of corrosion. By addressing these underlying causes, industries can mitigate the risks and challenges associated with corrosion in their melting operations.

The Benefits of Corrosion-Resistant SiC Crucibles

Faced with the limitations of traditional crucible materials, industries have sought out more durable and corrosion-resistant alternatives. One such solution that has gained widespread recognition is the use of silicon carbide (SiC) crucibles. These specialized crucibles offer a range of benefits that make them a compelling choice for a wide variety of melting applications.

SiC is a ceramic material that is renowned for its exceptional resistance to corrosion, thermal shock, and high temperatures. Unlike graphite or clay crucibles, SiC crucibles can withstand the harsh conditions encountered in many industrial melting processes, including exposure to molten metals, aggressive chemicals, and extreme temperatures. This enhanced resistance to corrosion and degradation ensures that SiC crucibles maintain their structural integrity and performance over an extended period, reducing the need for frequent replacement.

Moreover, the unique properties of SiC crucibles, such as their excellent thermal conductivity and heat resistance, offer significant advantages in terms of melting efficiency and product quality. By providing consistent and uniform heating throughout the crucible, SiC crucibles help to minimize hot spots and ensure that the molten material is heated evenly, leading to improved process control and better overall results.

Enhanced Durability and Longer Lifespan

One of the primary advantages of using a corrosion-resistant SiC crucible is its exceptional durability and extended lifespan. Unlike traditional crucibles that can quickly deteriorate due to the harsh operating conditions, SiC crucibles are engineered to withstand the rigors of high-temperature melting environments.

The inherent resistance of SiC to chemical attack, thermal shock, and physical wear and tear allows these crucibles to maintain their structural integrity for significantly longer periods. This extended lifespan translates into reduced downtime, fewer interruptions in production, and lower maintenance costs associated with frequent crucible replacements.

Moreover, the durability of SiC crucibles enables them to handle a wider range of molten materials, including highly corrosive substances, without compromising their performance. This versatility is particularly valuable in industries that work with a diverse array of materials, as it allows for a single crucible solution to be utilized across multiple melting processes.

Improved Melting Efficiency and Heat Transfer

In addition to their superior corrosion resistance, SiC crucibles also offer enhanced thermal properties that contribute to improved melting efficiency and heat transfer. The high thermal conductivity of SiC allows for efficient and uniform heat distribution throughout the crucible, ensuring that the molten material is heated evenly and consistently.

This improved heat transfer results in several key benefits. First, it helps to minimize hot spots within the crucible, which can lead to uneven heating and potentially compromise the quality of the final product. By maintaining a more consistent temperature profile, SiC crucibles help to ensure that the melting process is optimized, leading to better control over the material properties and characteristics.

Furthermore, the efficient heat transfer capabilities of SiC crucibles can translate into energy savings for the industrial operation. By requiring less energy input to achieve the desired melting temperatures, these crucibles can contribute to overall cost reductions and improved sustainability in the manufacturing process.

Reduced Contamination and Impurities

One of the significant challenges associated with traditional crucible materials is the risk of contamination and the introduction of impurities into the molten material. This is a critical concern for industries that require high-purity products, such as those in the electronics, aerospace, or medical device manufacturing sectors.

SiC crucibles, however, offer a distinct advantage in this regard. The inherent corrosion resistance of SiC ensures that the crucible material itself does not leach or react with the molten material, minimizing the risk of contamination. This is particularly important when working with sensitive or high-value materials, where even trace amounts of impurities can have a detrimental impact on the final product's performance and quality.

By reducing the potential for contamination, SiC crucibles help to maintain the purity and integrity of the melted material, contributing to improved product quality and consistency. This, in turn, can lead to increased customer satisfaction, reduced waste, and higher overall process efficiency.

Cost Savings and Return on Investment

While the initial investment in a SiC crucible may be higher compared to traditional crucible materials, the long-term benefits and cost savings can make it a highly attractive and cost-effective solution.

The extended lifespan of SiC crucibles, as discussed earlier, translates into fewer replacement costs and reduced downtime associated with crucible failures. This, in turn, leads to a lower overall cost of ownership and a better return on investment over the life of the crucible.

Additionally, the improved melting efficiency and reduced energy consumption of SiC crucibles can contribute to significant cost savings in the manufacturing process. By optimizing the heating and melting operations, industries can benefit from lower energy bills and improved overall process sustainability.

Furthermore, the reduced risk of contamination and the improved quality of the final product can have far-reaching financial implications. Minimizing the need for rework, scrap, or product recalls can lead to substantial cost savings and a better bottom line for the business.

Applications and Industries that Benefit from SiC Crucibles

The corrosion-resistant and high-performance properties of SiC crucibles make them a versatile solution for a wide range of industries and applications. Some of the key sectors that can benefit from the use of SiC crucibles include:

1. Metals and Alloy Melting: SiC crucibles are well-suited for melting a variety of metals and alloys, including aluminum, copper, brass, and stainless steel, due to their exceptional resistance to high temperatures and molten metal corrosion.

2. Glass and Ceramic Manufacturing: The thermal shock resistance and chemical inertness of SiC crucibles make them ideal for melting and processing glass, ceramics, and other high-temperature materials.

3. Electronics and Semiconductor Industry: The purity and contamination-resistant nature of SiC crucibles are crucial in the production of electronic components, semiconductors, and other high-tech products that require the utmost material quality.

4. Aerospace and Defense: SiC crucibles are commonly used in the production of specialized alloys and advanced materials for the aerospace and defense industries, where reliability, performance, and safety are paramount.

5. Medical Device Manufacturing: The corrosion resistance and purity of SiC crucibles are essential in the production of medical devices, implants, and other healthcare-related products that require strict quality control and material integrity.

6. Jewelry and Precious Metals: SiC crucibles are well-suited for melting and casting precious metals, such as gold, silver, and platinum, without the risk of contamination or degradation.

Across these diverse industries, the benefits of using a corrosion-resistant SiC crucible – including enhanced durability, improved melting efficiency, reduced contamination, and cost savings – make it a compelling choice for companies seeking to optimize their melting operations and maintain the highest product quality.

Choosing the Right SiC Crucible for Your Melting Needs

When selecting a SiC crucible for your specific melting requirements, it is essential to consider several key factors to ensure that you choose the right solution for your needs.

First and foremost, it is crucial to carefully assess the characteristics of the materials you will be melting, including their chemical composition, melting point, and any potential corrosive properties. This information will help you determine the appropriate grade and composition of the SiC crucible that can withstand the harsh operating conditions and provide the necessary level of corrosion resistance.

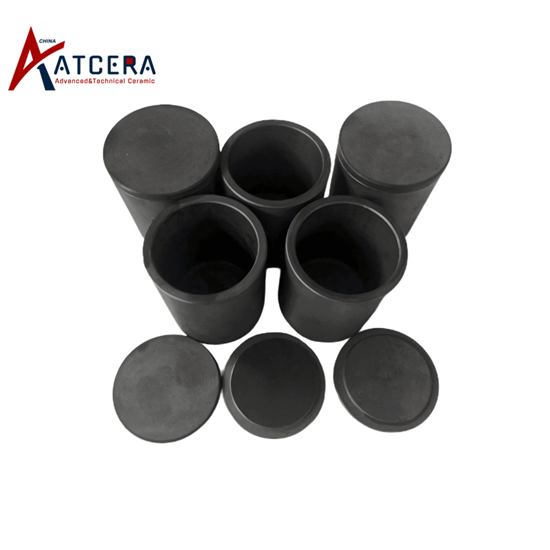

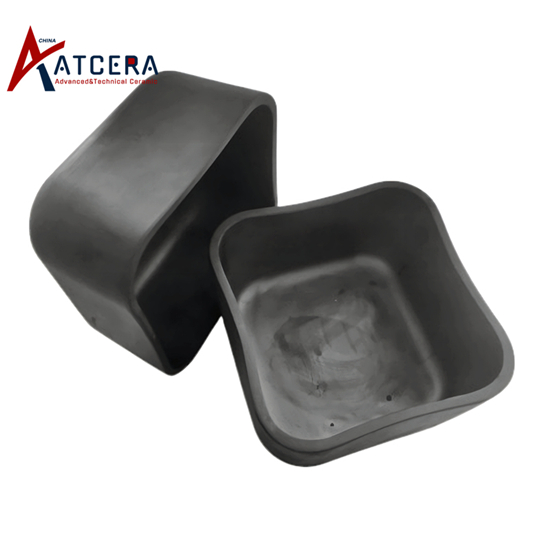

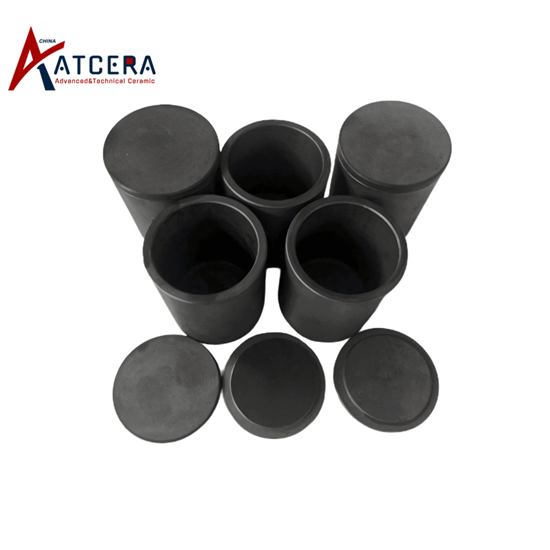

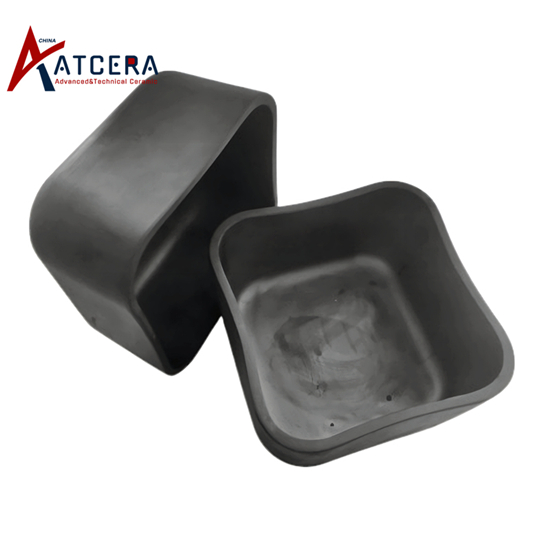

Additionally, the size and shape of the crucible should be tailored to the specific requirements of your melting process and the volume of material you need to handle. SiC crucibles are available in a wide range of sizes and geometries, allowing you to select the most suitable option for your production needs.

Other important considerations when choosing a SiC crucible include the manufacturing process, quality control measures, and the supplier's reputation and expertise. Opting for a high-quality, well-engineered SiC crucible from a reputable manufacturer can ensure that you receive a durable, reliable, and consistent product that will deliver the desired performance and benefits.

Conclusion

In conclusion, the use of a corrosion-resistant SiC crucible can be a game-changer for industries that rely on melting and processing a wide range of materials. The exceptional durability, improved melting efficiency, reduced contamination risk, and long-term cost savings offered by SiC crucibles make them a highly compelling solution for a variety of industrial applications.

By investing in a SiC crucible, companies can optimize their melting operations, improve product quality, and enhance their overall competitiveness in the market. As the demand for high-performance, sustainable, and cost-effective melting solutions continues to grow, the adoption of SiC crucibles is poised to become increasingly widespread across various industries.

Whether you are working with metals, alloys, ceramics, or specialized materials, a corrosion-resistant SiC crucible can provide the reliable and efficient performance you need to take your melting processes to new heights. Embrace the benefits of this innovative technology and unlock the full potential of your industrial operations.