As a kind of widely used non-metal material, quartz has the following features, so it is used to produce various optical products, and instruments for semiconductor and solar cell production.

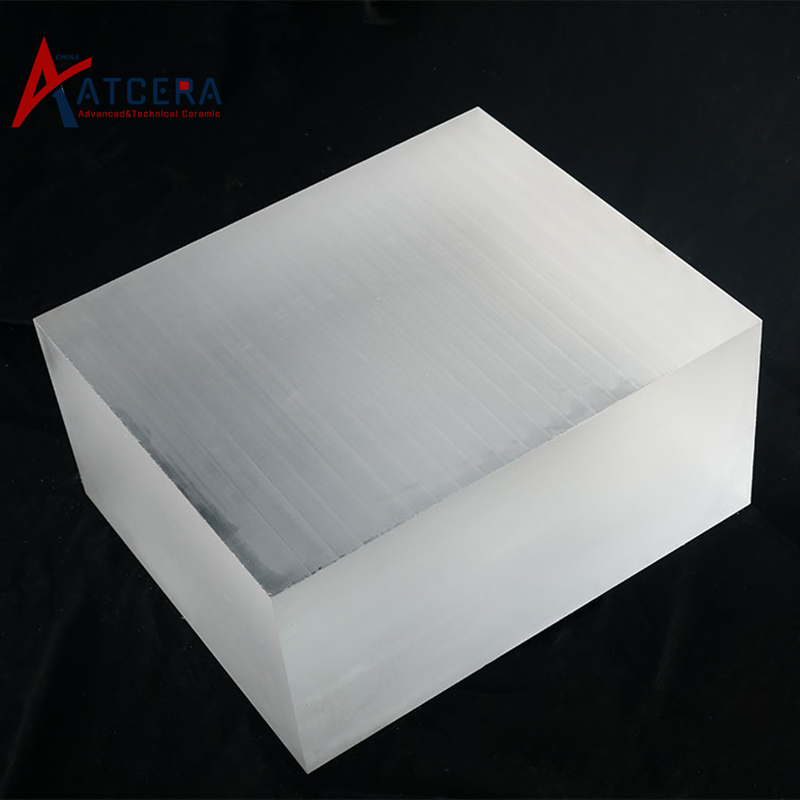

1. High temperature resistance, quartz softening point temperature is about 1730℃, it can be used at 1100℃ for a long time, short time maximum use temperature up to higher than 1450℃;

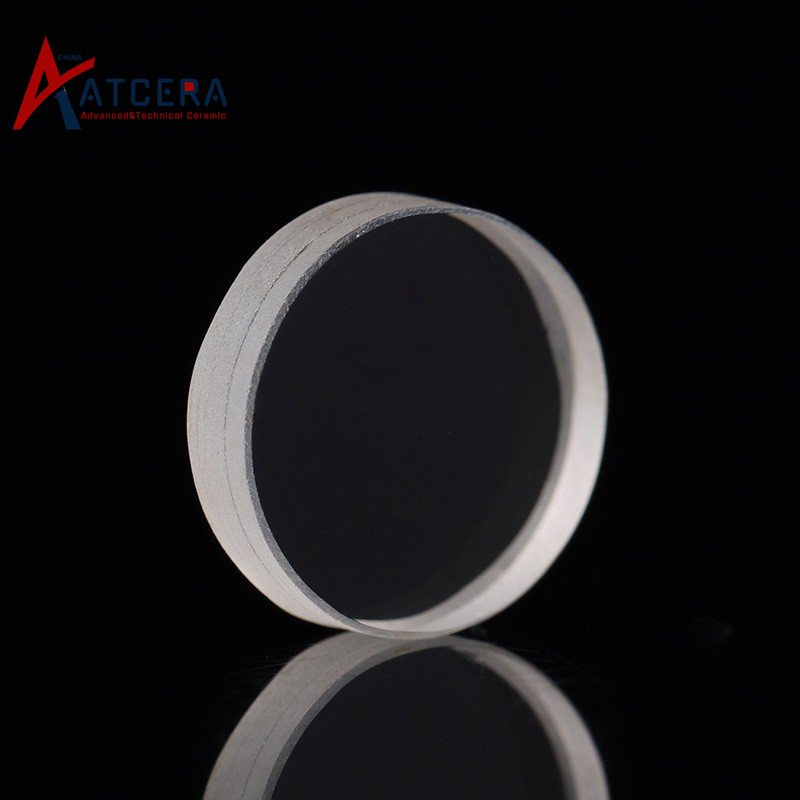

2. Quartz has good light transmission and stable optical performance, the transparent range is wide, which is from 120nm-4500nm for normal pure quartz, and there is no absorption peak in this spectrum range. Also filter UV quartz can be produced by adding some additive into the raw material, to effectively block UV radiation (wavelength 190-320nm)

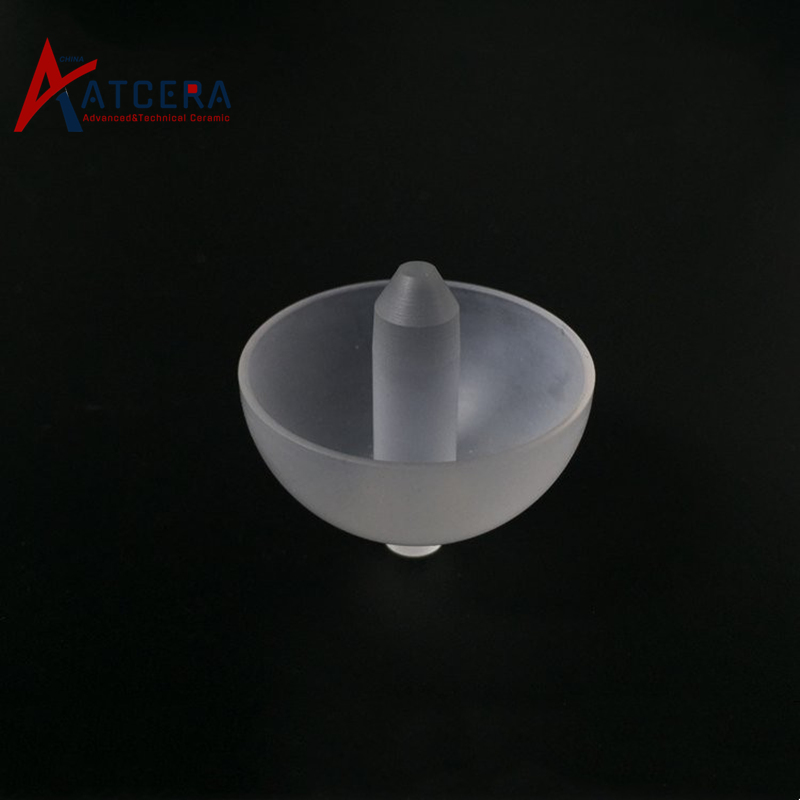

3. Quartz has good corrosion resistance, can contact directly with various acids, alkalis and chemical reagents, and has good chemical stability;

4. Electrical insulation performance of quartz is excellent, even at high temperatures quartz rod also has good insulation performance.