Boron nitride has a variety of crystal structures, including the most common hexagonal structure (h-BN), high-hardness cubic structure (c-BN), and the rhombic structure (r-BN) generated during the crystal phase transition process, in addition to wurtzite type boron nitride (w-BN) and two-dimensional boron nitride crystal.

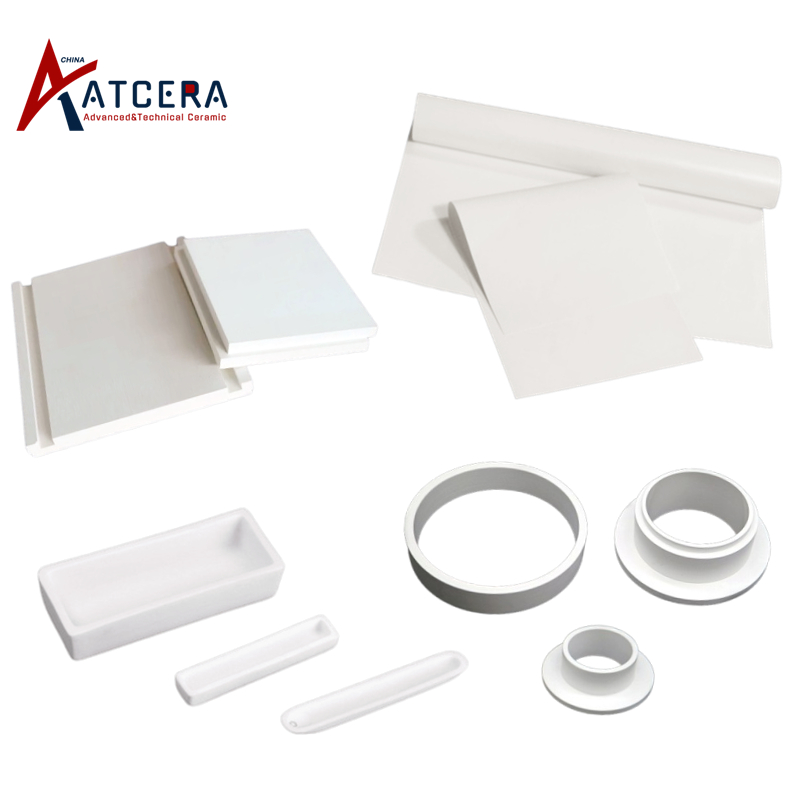

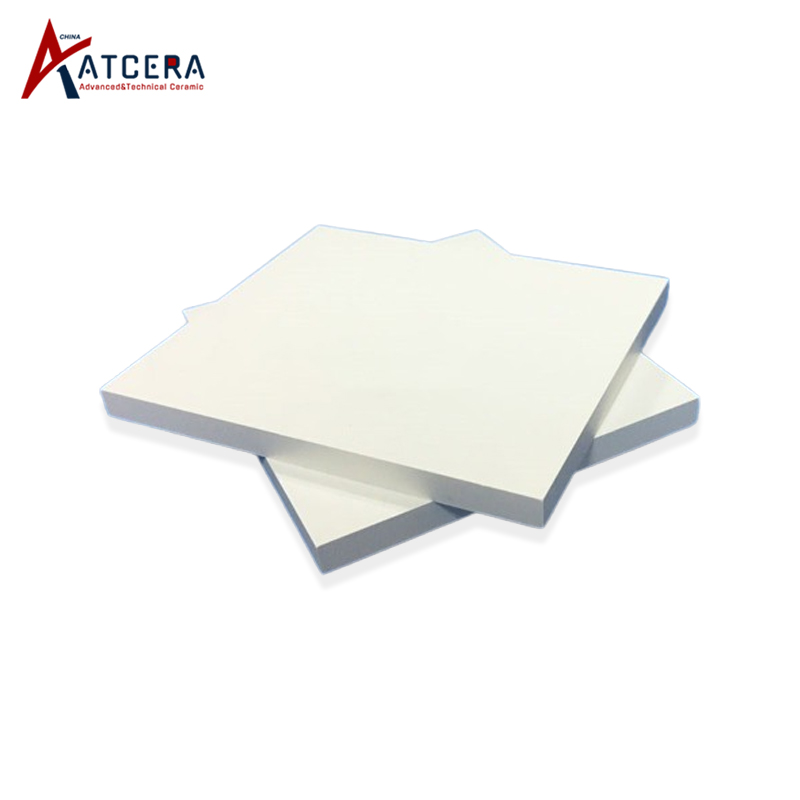

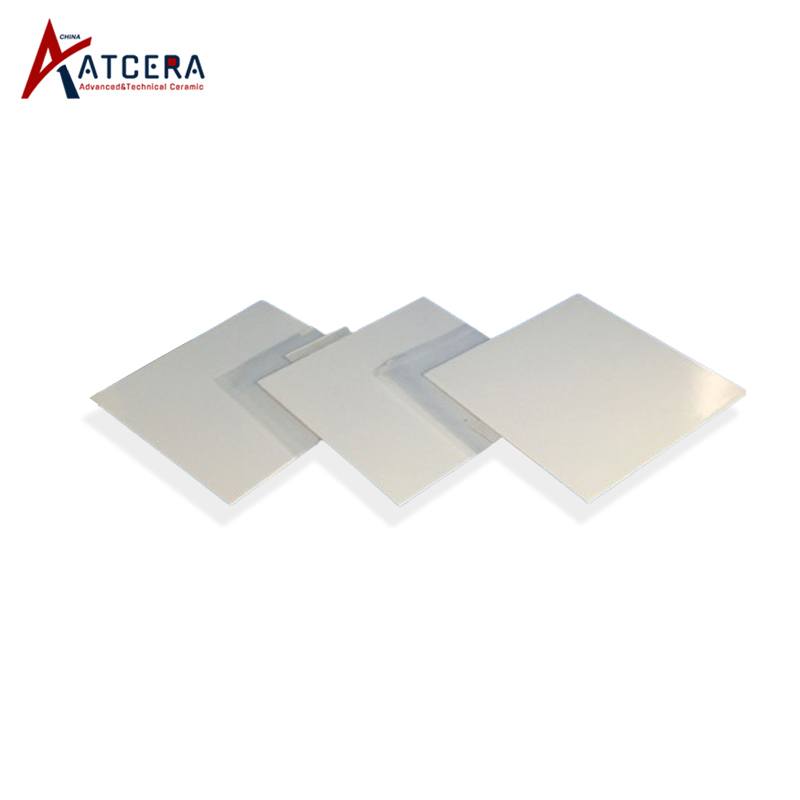

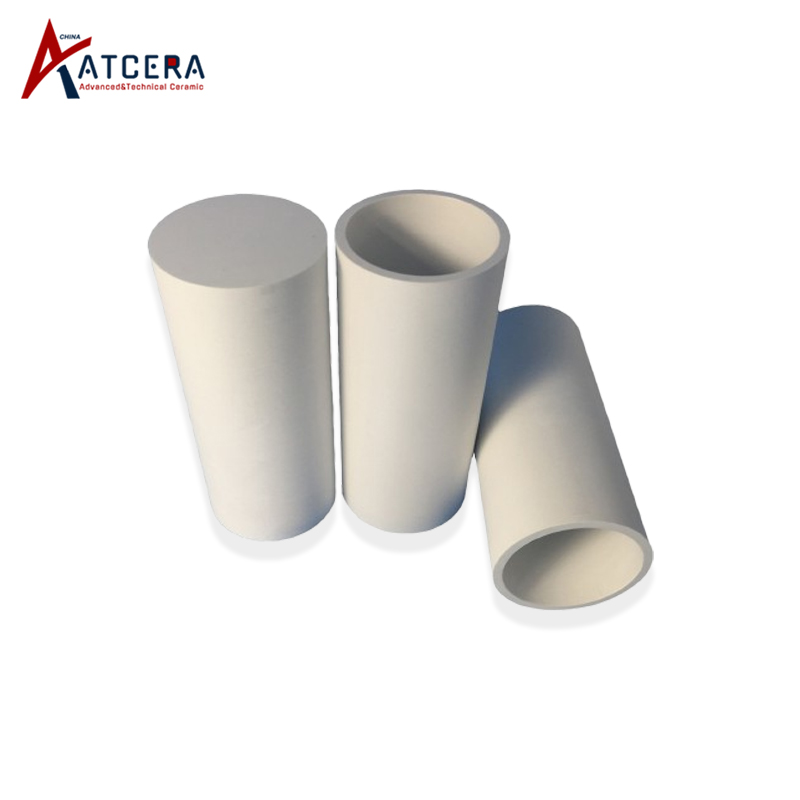

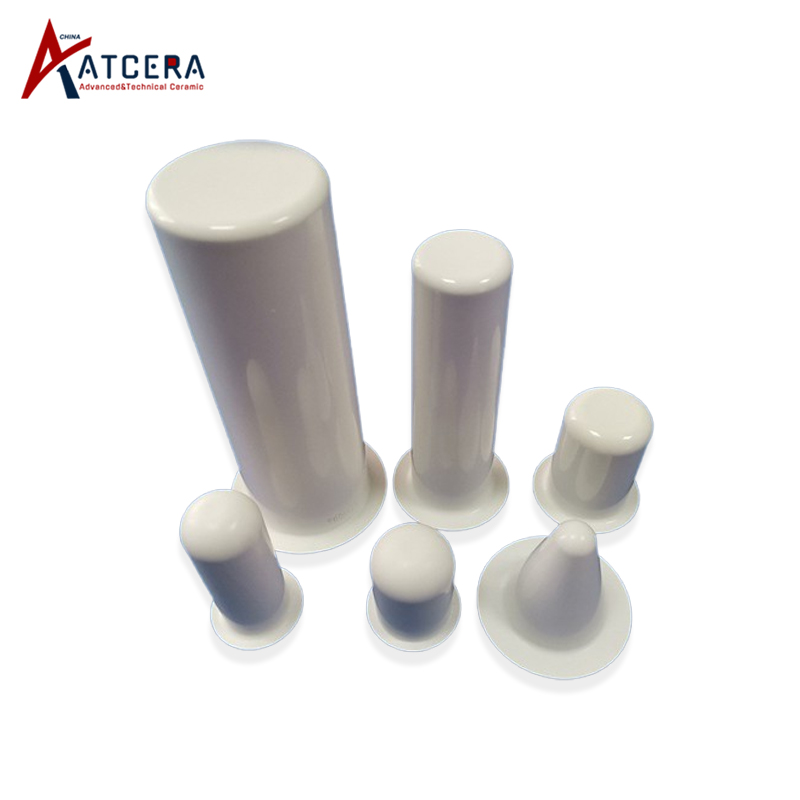

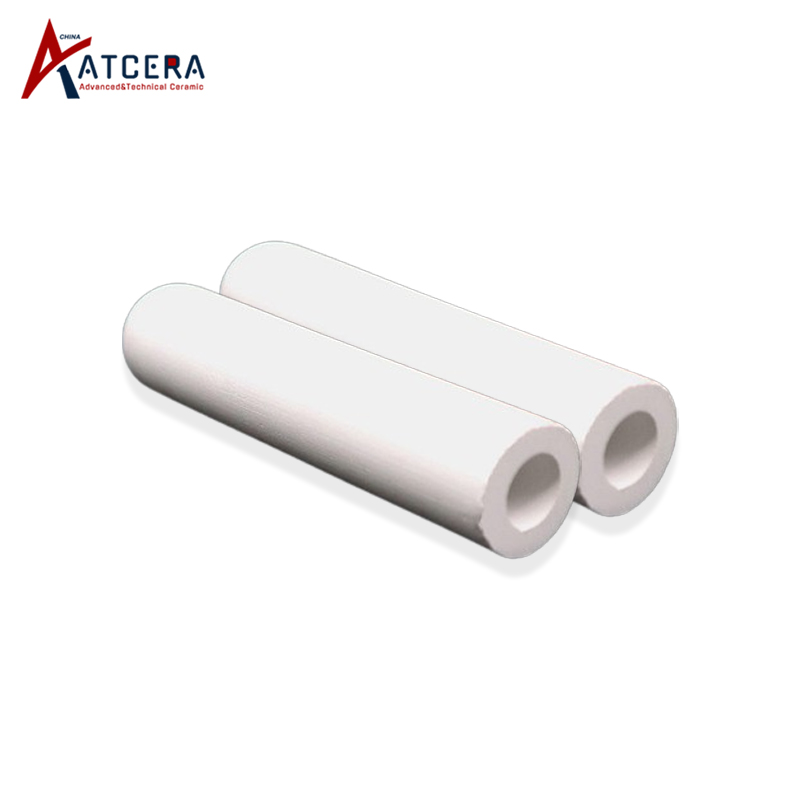

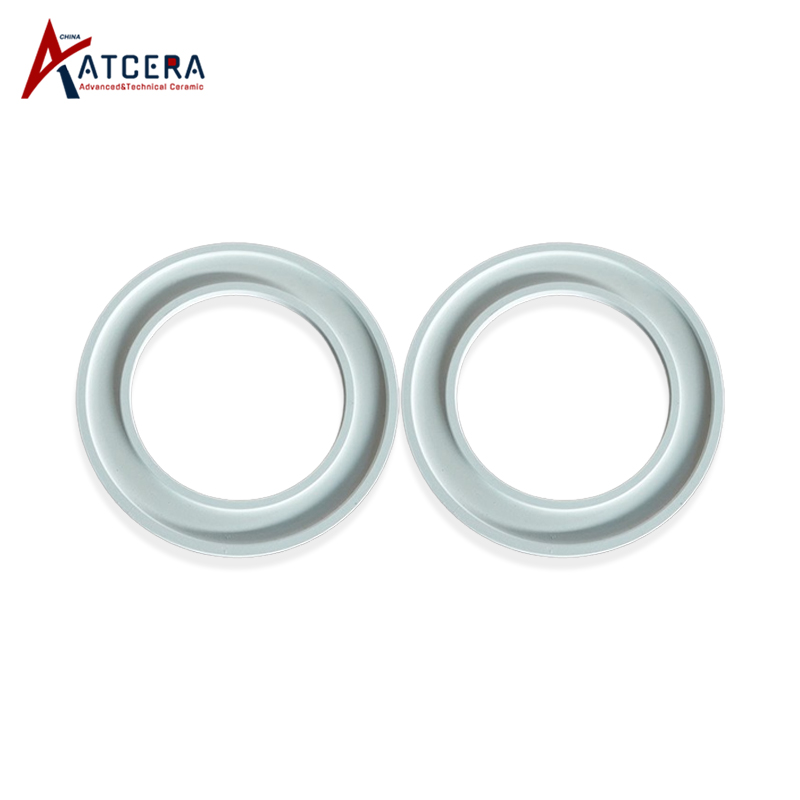

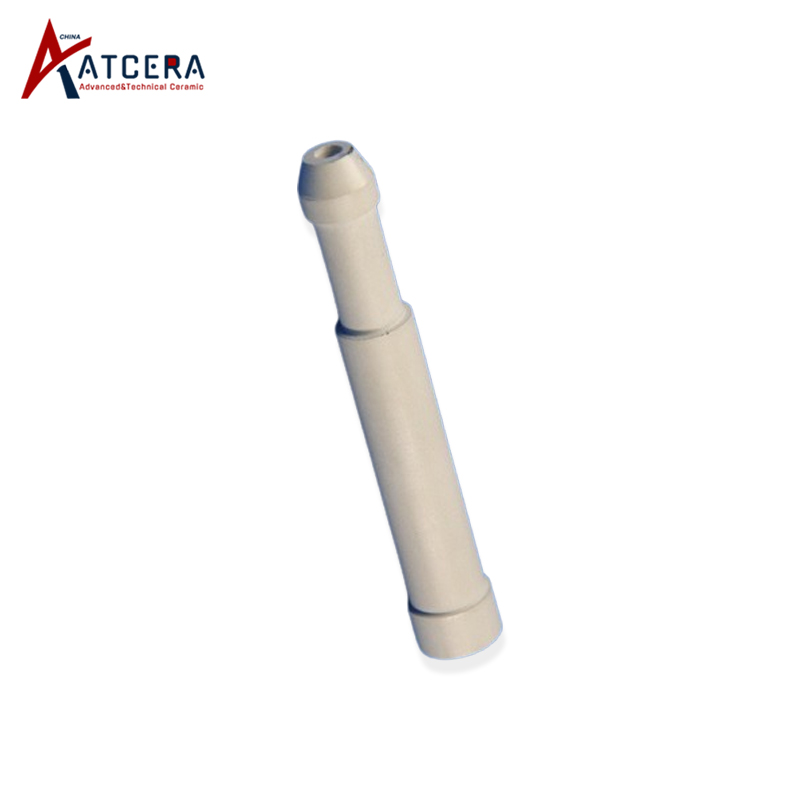

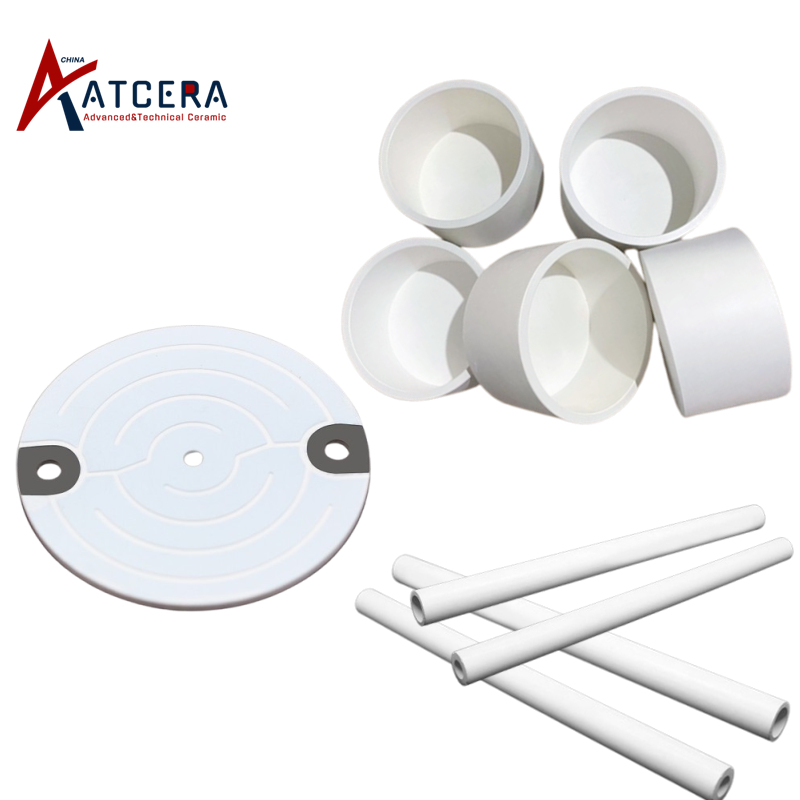

Hexagonal structure boron nitride can be fabricated by hot press sintering or pyrolysis process, with high temperature and corrosion resistance, good insulation and thermal stability, and it is widely used to produce crucible, insulating parts and high temperature and corrosion resistance parts.

Cubic boron nitride is synthesized by hexagonal boron nitride under high temperature condition, with extremely high hardness, second only to diamond, it is commonly used to manufacture machining tools and abrasive tools.

| view all boron nitride ceramic products |

According to your application scenario, analyze the needs, choose the appropriate material and processing plan.

According to your application scenario, analyze the needs, choose the appropriate material and processing plan. Professional team, quick response, can provide solutions and quotations within 24 hours after confirming the demand.

Professional team, quick response, can provide solutions and quotations within 24 hours after confirming the demand. Flexible business cooperation mechanism, support at least one piece of quantity customization.

Flexible business cooperation mechanism, support at least one piece of quantity customization. Quickly provide samples and test reports to confirm that the product meets your needs.

Quickly provide samples and test reports to confirm that the product meets your needs. Provide product use and maintenance suggestions to reduce your cost of use.

Provide product use and maintenance suggestions to reduce your cost of use.