Boron carbide ceramic is made of boron carbide powder as the main raw material, after forming and sintering to obtain a stable crystalline phase structure, it has the characteristics of high temperature resistance, high hardness, good wear resistance, corrosion resistance, light weight, good thermal shock resistance and oxidation resistance, it is widely used in mechanical engineering, semiconductor, petrochemical, electric power, environmental protection and energy saving, national defense and other industries.

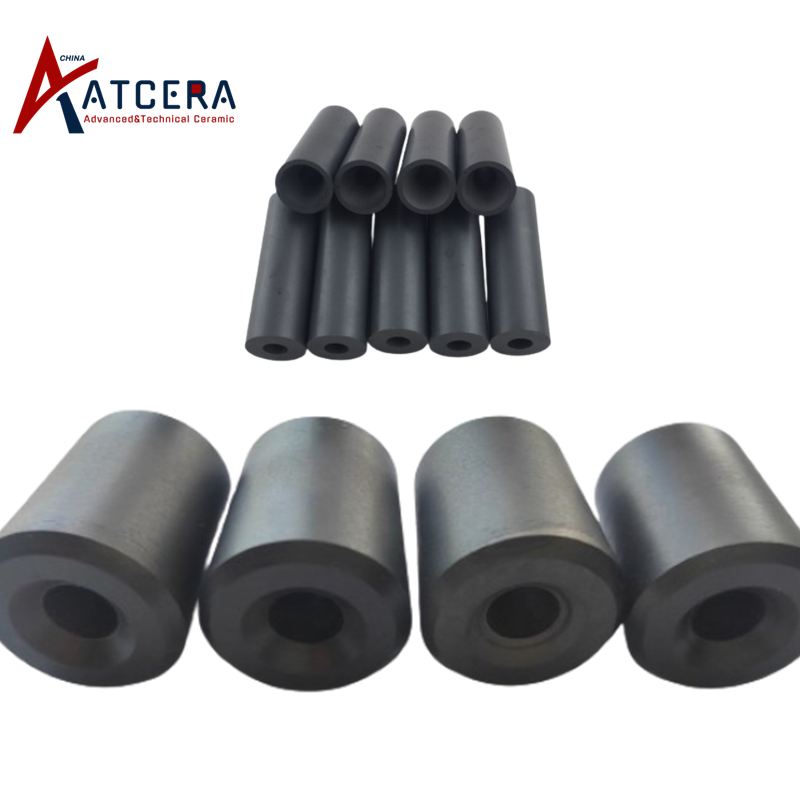

As our important product, ATCERA can produce various boron carbide sandblasting nozzles, rings and other mechnical parts.

| view all boron carbide mechanical parts |