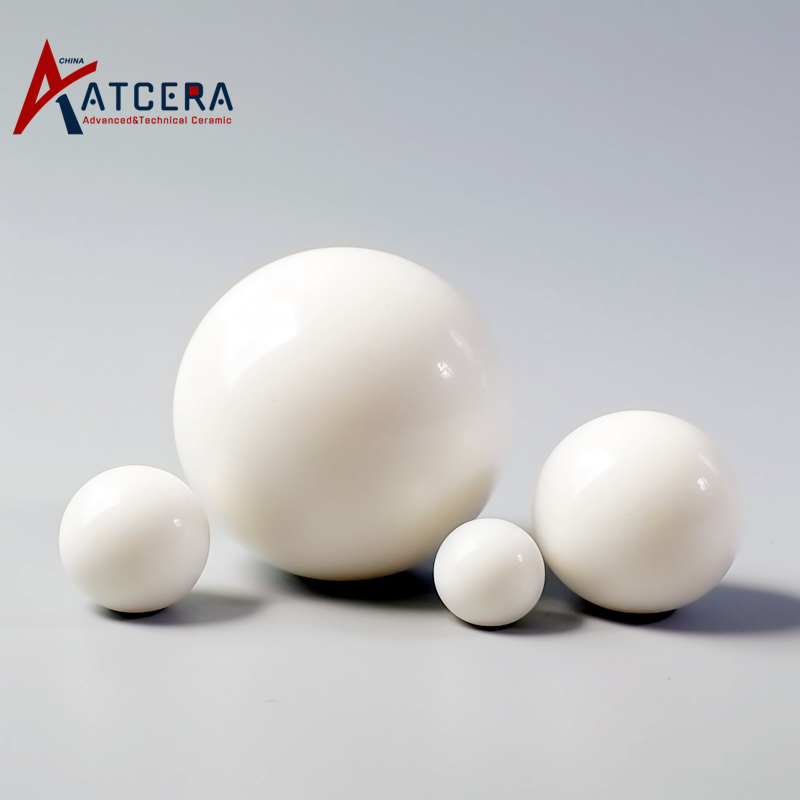

In the dynamic landscape of industrial materials, advanced technical ceramic balls have emerged as a pivotal component, revolutionizing the performance of numerous applications. With the relentless pursuit of efficiency, durability, and precision, these ceramic balls are poised to reshape the future of various industries. This article delves into the characteristics, applications, selection criteria, manufacturing process, and success stories of advanced technical ceramic balls, aiming to provide a comprehensive guide for those seeking to leverage their unique benefits.

Characteristics of Advanced Technical Ceramic Balls

Advanced technical ceramic balls are distinguished by their exceptional properties, stemming from their high-purity, ultra-fine inorganic compound powders. These materials, through precision manufacturing and structural design, exhibit unparalleled hardness, wear resistance, corrosion resistance, and thermal stability. These characteristics enable ceramic balls to operate efficiently in extreme environments, reducing downtime and enhancing overall system performance.

Application Fields of Advanced Technical Ceramic Balls

The versatility of advanced technical ceramic balls is evident in their widespread adoption across numerous industries. In the chemical and petrochemical sectors, ceramic balls are used in valves, pumps, and mixing equipment, ensuring smooth fluid flow and minimizing wear. In the automotive industry, they find applications in bearings and transmission systems, enhancing durability and reducing friction. Additionally, they are employed in the aerospace, medical, and electronics industries, where their superior performance is crucial for ensuring precision and reliability.

How to Select the Right Advanced Technical Ceramic Ball for Your Project

Choosing the appropriate advanced technical ceramic ball for a specific project requires careful consideration of various factors. Material selection is paramount, as different ceramic compositions offer varying degrees of hardness, wear resistance, and corrosion resistance. The intended application's operating conditions, such as temperature, pressure, and chemical environment, must also be taken into account. Moreover, the required precision and surface finish of the ceramic ball should align with the project's specifications. Consulting with experienced suppliers or technical experts can provide valuable insights into making an informed decision.

Manufacturing Process of Advanced Technical Ceramic Balls

The manufacturing process of advanced technical ceramic balls involves intricate steps, ensuring the highest quality and consistency. Starting with the selection of high-purity, ultra-fine inorganic compound powders, the materials undergo rigorous blending and forming processes. Precision machining and finishing techniques are then employed to achieve the desired shape, size, and surface finish. Quality control measures are implemented throughout the process, ensuring that each ceramic ball meets stringent standards for performance and reliability.

Case Studies and Success Stories of Using Advanced Technical Ceramic Balls

Numerous case studies and success stories illustrate the impact of advanced technical ceramic balls in various industries. For instance, a leading chemical processing plant replaced traditional metal balls in its valves with ceramic balls, resulting in significantly reduced wear and improved fluid flow. In another instance, an automotive manufacturer integrated ceramic balls into its transmission system, achieving smoother operation and longer service life. These examples demonstrate the tangible benefits of advanced technical ceramic balls in enhancing system performance and reducing maintenance costs.

Conclusion

Advanced technical ceramic balls represent a significant advancement in industrial materials, offering unprecedented performance and reliability. Their unique properties, versatile applications, and precision manufacturing processes position them as a key enabler for numerous industries seeking to achieve greater efficiency and durability. By understanding their characteristics, applications, and selection criteria, businesses can leverage the power of advanced technical ceramic balls to drive innovation and success in their respective fields.