In the rapidly evolving world of industrial materials, zirconia balls and beads have emerged as a game-changer. Their unique properties and versatility have opened up new possibilities in various industries, especially those requiring ultra-fine grinding and dispersion of high-hardness abrasive materials. As an industrial ceramic engineer with over a decade of experience in Europe and the Americas, I have witnessed the remarkable progress zirconia balls and beads have brought to numerous applications.

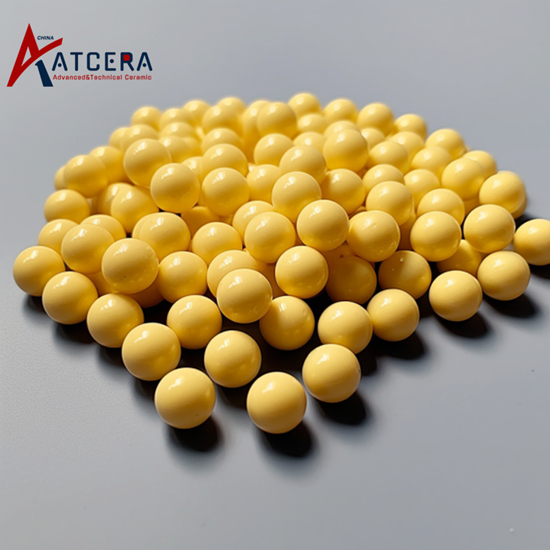

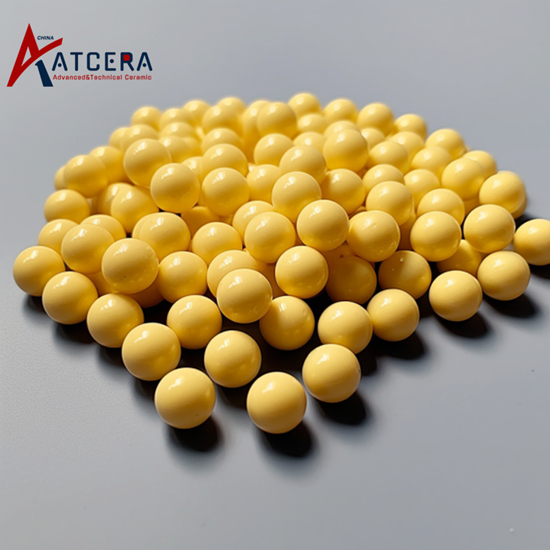

Characteristics of Zirconia Balls & Beads

Zirconia balls and beads, or high wear-resistant zirconia grinding media, are a testament to the advancements in technical ceramics. Their combination of high strength, hardness, and fracture toughness makes them ideal for demanding applications. Additionally, their minimal wear, high temperature resistance, corrosion resistance, and electrical insulation properties further solidify their position as a premier choice.

Application Fields of Zirconia Balls & Beads

The diverse applications of zirconia balls and beads are a testament to their unparalleled performance. They are widely used in the ultra-fine grinding and dispersion of high-hardness abrasive materials in industries such as dyes and coatings, electronic materials, medicine, food, and lithium battery raw materials. Zirconia's ability to provide large shearing force during grinding, coupled with its excellent wear resistance, ensures high grinding efficiency and extended service life.

How to Select the Right Zirconia Balls & Beads for Your Project

Choosing the right zirconia balls and beads for your specific project is crucial. Consider factors such as the material's hardness, abrasiveness, and viscosity. Zirconia's excellent properties allow it to handle even the most challenging materials, ensuring a smooth and efficient grinding process. Furthermore, its compatibility with various ball mills and sand mills makes it a versatile choice for a wide range of applications.

Manufacturing Process of Zirconia Balls & Beads

The manufacturing process of zirconia balls and beads involves the use of high-purity, ultra-fine inorganic compound powders. These powders undergo precise manufacturing processes and structural design to produce the final product. The result is a technically advanced ceramic material that meets the highest standards of performance and durability.

Case Studies and Success Stories of Using Zirconia Balls & Beads

Over the years, zirconia balls and beads have been successfully implemented in numerous applications, delivering exceptional results. One such case study involves the use of zirconia grinding media in the production of high-end electronic materials. The zirconia balls and beads provided the necessary grinding force and precision, resulting in a significant improvement in product quality and production efficiency.

Conclusion

Zirconia balls and beads are a testament to the power of advanced industrial ceramics. Their unique properties and versatility have revolutionized the ultra-fine grinding and dispersion of high-hardness abrasive materials. As we continue to push the boundaries of technological innovation, zirconia balls and beads will undoubtedly play a crucial role in shaping the future of numerous industries.