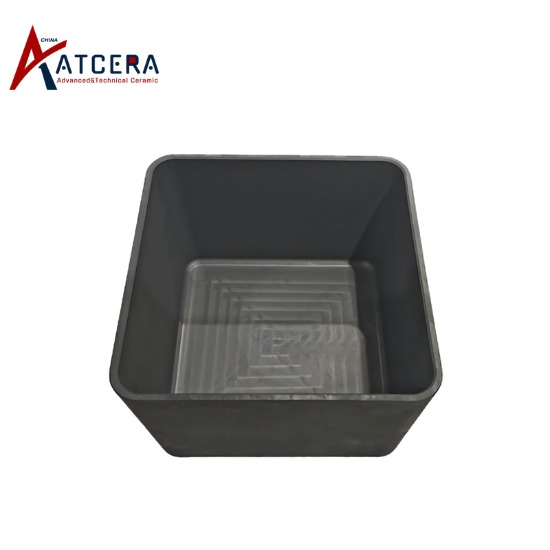

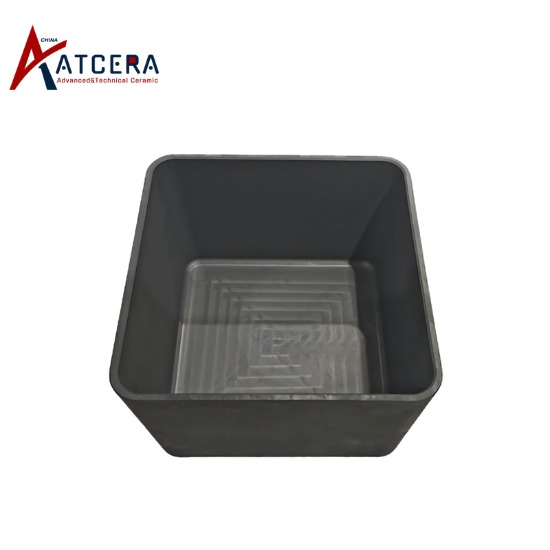

Silicon carbide crucible is widely used in high temperature industries such as ceramics, metallurgy and glass because of its excellent high temperature resistance, corrosion resistance and high strength. Press forming is a common forming method in the manufacture of sic crucible. Its technological process and parameter control have important influence on the final performance of crucible. The purpose of this paper is to discuss the pressing process of silicon carbide crucible, in order to provide theoretical basis and technical support for the production of silicon carbide crucible.

Raw material mixing and preparation

The press forming process of sic crucible first involves the mixing and preparation of raw materials. Raw materials mainly include silicon carbide powder, binder, plasticizer and so on. These raw materials are mixed evenly in a certain proportion to form a plastic mud. The mixing process of raw materials needs to strictly control the ratio to ensure the uniform distribution of each component, which provides a good foundation for subsequent molding.

Pressing molding process

The mixed mud is put into the forming mold, and pressure is applied by a hydraulic press or other pressing equipment to shape the mud into the desired crucible shape in the mold. In the process of pressing, the control of pressure, temperature and other parameters is very important. Proper pressure helps to ensure the density and strength of the crucible, while temperature control affects the flow and forming effect of the mud.

Press forming has the advantages of high production efficiency, precise shape and size of crucible. The forming quality and production efficiency of crucible can be further improved by optimizing the pressing parameters, such as pressure, pressing time and die temperature.

The advantages of pressing molding process

The press forming process has obvious advantages in the manufacture of sic crucible. First, the process has high production efficiency and is suitable for mass production, which helps to reduce production costs. Secondly, press forming can ensure the accuracy of the shape and size of the crucible and meet the strict requirements for the performance of the crucible in the high-temperature industry. In addition, by adjusting the pressing parameters, the crucible performance can be customized to meet the needs of different customers and application scenarios.

To sum up, the pressing process plays an important role in the manufacture of sic crucible. Silicon carbide crucible with excellent performance can be prepared by optimizing the process of raw material mixing, pressing and forming and parameter control. In the future, with the continuous development of the high-temperature industrial field, the demand for silicon carbide crucible will further increase. Therefore, it is of great significance to promote the development of silicon carbide crucible industry to further study the pressing forming process and improve the forming quality and production efficiency of crucible. At the same time, it is also necessary to pay attention to the application of new forming technologies and materials to expand the application field and performance advantages of silicon carbide crucible.