Because silicon nitride ceramics are strong covalent bond compounds, heat transfer can only be completed through lattice vibration, affected by factors such as density, phase composition, microstructure and lattice oxygen, the actual thermal conductivity of silicon nitride ceramics is usually much lower than the theoretical value, which is currently the biggest bottleneck limiting the application of silicon nitride substrates.

Density and Phase Composition

Generally, because the reduction of pores in ceramics can make the microstructure more compact, the conduction path of phonons in the material is more continuous, thus reducing the scattering of phonons. Therefore, increasing the density of silicon nitride ceramics as much as possible is a prerequisite for obtaining high thermal conductivity silicon nitride ceramics.

Silicon nitride ceramics also have a greater influence on the thermal conductivity, silicon nitride has α and β two crystal phases, due to the low structural symmetry of α-Si3N4, its cell has more cavities, can accommodate more impurity ions, the scattering effect of phonons is stronger. In addition, the oxygen content of α-Si3N4 is much higher than that of β-Si3N4, and oxygen impurities will produce solid solution reactions to generate silicon vacancies, and also cause phonon scattering, which will lead to the reduction of thermal conductivity. In the liquid-phase sintering process, the α phase is gradually transformed into β phase. With the increase of β phase content relative to α phase content, the thermal conductivity of silicon nitride ceramics is gradually increased.

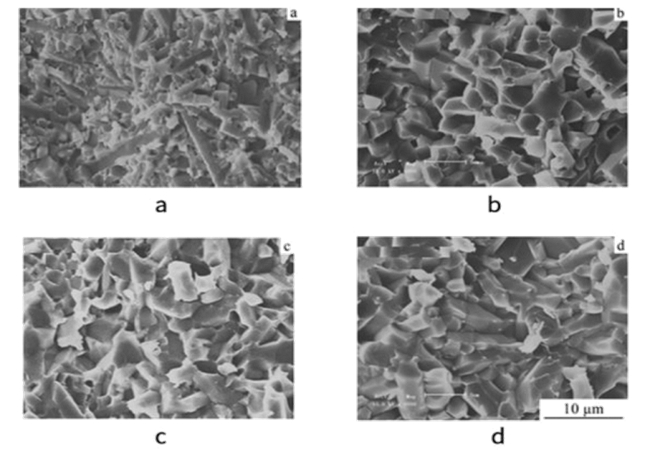

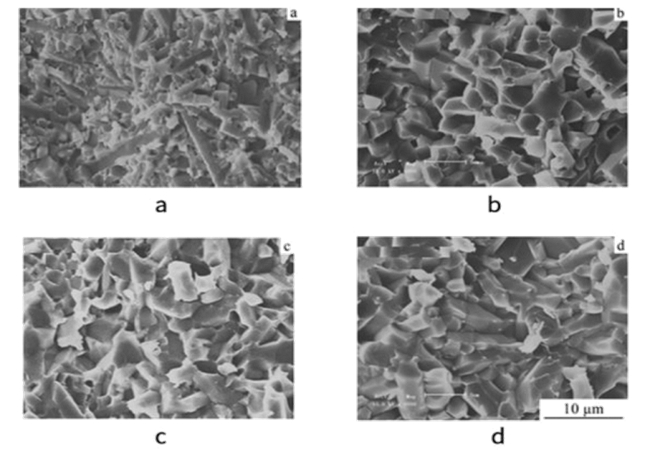

Micro-Morphology

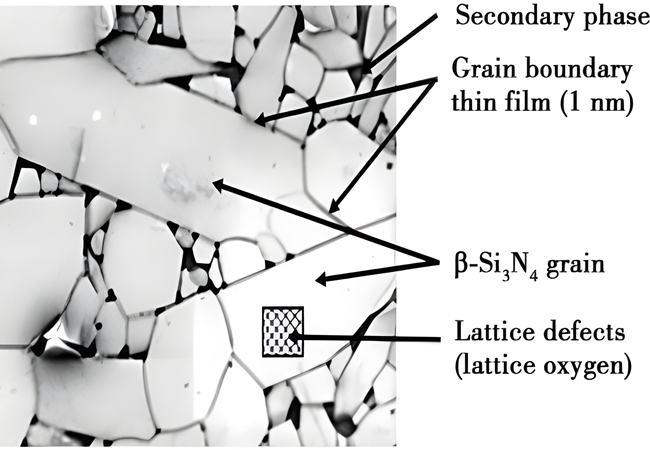

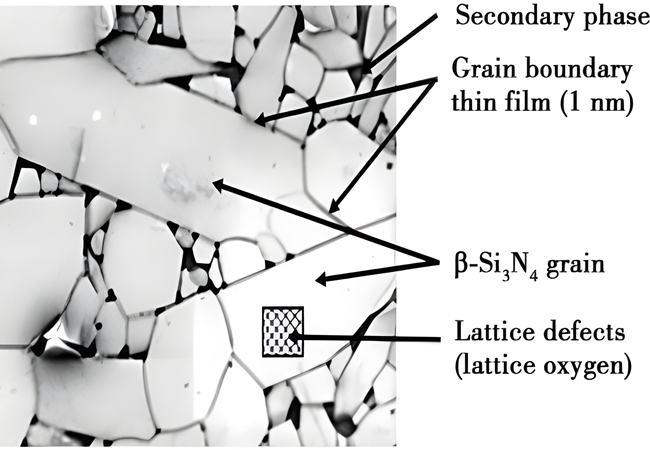

The grain size, grain boundary film thickness and glass phase content have important effects on the thermal conductivity of silicon nitride. During the liquid phase sintering of silicon nitride ceramics, the liquid phase of nitrogen oxide compound formed by the reaction of the additives and SiO2 on the surface at high temperature is conducive to the densification of the ceramics. After cooling, the liquid phase will remain in the silicon nitride ceramics, and the thermal conductivity is very low. Part of the formed glass phase exists in the form of grain boundary film, the thickness of about 1~2 nm; Another part of the excess glass phase forms a glass envelope at the junction of the long rod grains of β-Si3N4. The higher the grain boundary phase content with low thermal conductivity, the lower the thermal conductivity of silicon nitride ceramics.

In addition, the increase of grain size is conducive to the improvement of thermal conductivity, but when the grain size reaches the critical value, the increase of grain size has no obvious effect on the improvement of thermal conductivity of silicon nitride. Therefore, only through high temperature sintering and long-term heat preservation to promote the abnormal grain growth of silicon nitride can not continue to improve the thermal conductivity, it is necessary to explore other more effective ways.

Lattice Oxygen Content

In different sintering systems, the thermal conductivity of silicon nitride is negatively correlated with its lattice oxygen content. For a long time, researchers have been focusing on reducing the lattice oxygen content of solid solution in silicon nitride to improve the thermal conductivity of silicon nitride. By increasing the sintering temperature and extending the high temperature holding time, silicon nitride can be fully dissolved and precipitated in the liquid phase with lower viscosity, reducing lattice defects and increasing grain size, which plays an important role in improving the thermal conductivity of silicon nitride, but the resulting high cost is not conducive to the popularization and application of high thermal conductivity silicon nitride substrates.

Therefore, the composition of the liquid phase can be adjusted by selecting a powder with high purity and low oxygen content, and introducing non-oxide sintering additives, etc. The liquid phase with low oxygen content can hinder the formation of lattice oxygen in β-Si3N4, thus significantly improving the thermal conductivity. At present, in the background of low lattice oxygen content silicon nitride powder has not made significant breakthrough, it is an economical and effective way to use non-oxides instead of corresponding oxide sintering additives and regulate lattice oxygen content by adjusting liquid phase composition to improve the thermal conductivity of silicon nitride ceramics.