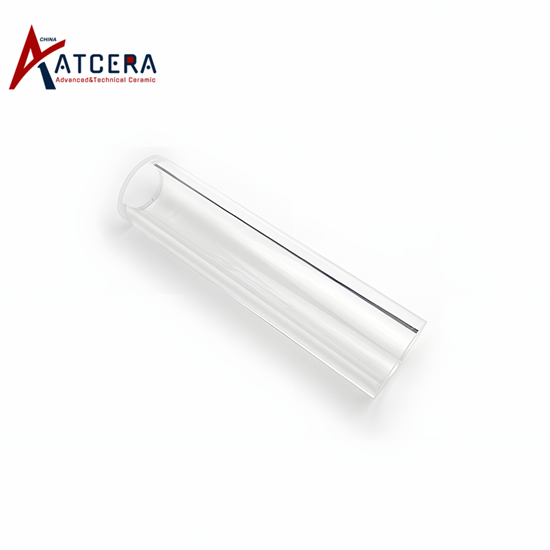

In the ever-evolving landscape of industrial lighting and material science, UV-Blocking Quartz Lighting Tubes have emerged as a pivotal component, catering to the stringent requirements of diverse industries across Europe and America. These advanced tubes, characterized by their exceptional optical properties and robust UV-blocking capabilities, have revolutionized applications ranging from semiconductor manufacturing to scientific research and medical equipment. As an engineer specializing in this field, I delve into the nuances of these tubes, exploring their unique features, widespread applications, and crucial areas of improvement tailored to address the evolving needs of our esteemed clients.

The Essence of UV-Blocking Quartz Lighting Tubes

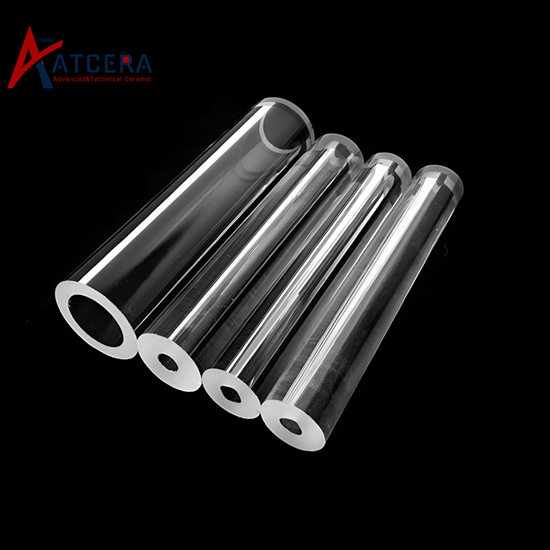

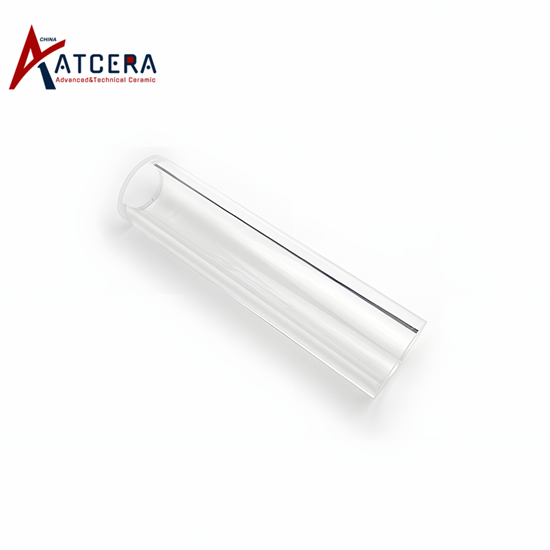

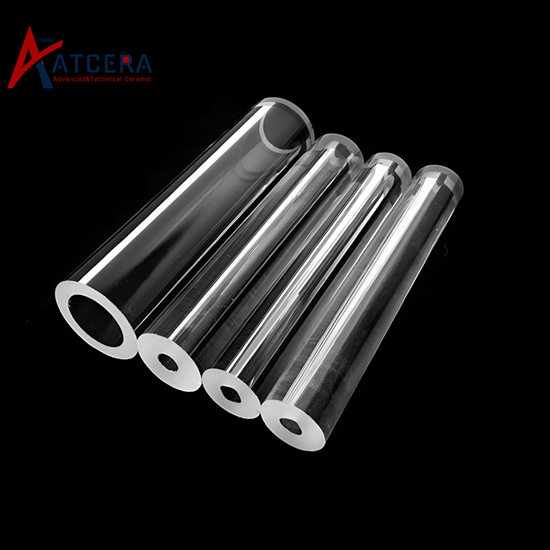

At the heart of UV-Blocking Quartz Lighting Tubes lies their unparalleled purity and resistance to thermal shock, enabling them to withstand extreme temperatures without compromising on their optical clarity. Their innate ability to effectively filter out harmful ultraviolet radiation, combined with exceptional transmittance across the visible spectrum, renders them indispensable in environments where precision and safety are paramount.

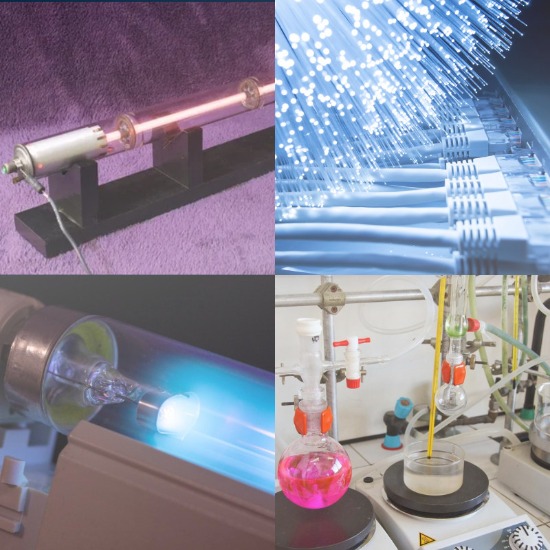

Widespread Applications

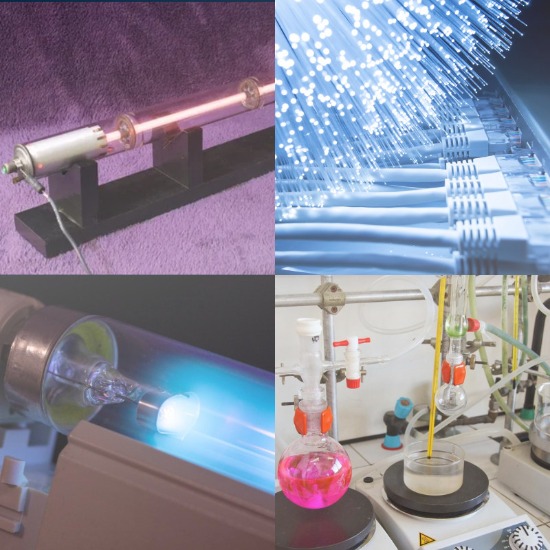

Semiconductor Manufacturing: UV-Blocking Quartz Lighting Tubes are essential in photolithography processes, ensuring precise pattern transfer onto silicon wafers while safeguarding delicate materials from UV damage.

Scientific Research: Researchers in fields such as spectroscopy and microscopy rely on these tubes for their high-quality light output, facilitating groundbreaking discoveries.

Medical Equipment: In medical lasers and UV sterilization systems, they play a vital role in maintaining sterility and precision during delicate procedures.

Photovoltaic Industry: Their UV-blocking properties enhance the efficiency of solar cells by minimizing degradation caused by UV exposure.

Addressing Customer Pain Points & Proposed Innovations

Pain Point 1: Enhancing Durability and Lifespan

Current Challenge: While quartz glass is inherently robust, prolonged exposure to harsh industrial conditions can lead to premature degradation.

Innovation: Incorporating advanced coating technologies, such as anti-reflective and scratch-resistant layers, can significantly extend the lifespan of UV-Blocking Quartz Lighting Tubes while maintaining optimal performance.

Pain Point 2: Customization for Specific Applications

Current Challenge: The diverse range of industrial applications necessitates tailored solutions, yet standardization often limits customization options.

Innovation: Developing a modular design approach that allows for easy modification of tube dimensions, UV-blocking spectra, and transmittance levels, thereby catering to the unique requirements of each customer.

Pain Point 3: Environmental Impact and Sustainability

Current Challenge: The production and disposal of quartz glass tubes can have environmental implications, particularly regarding energy consumption and waste management.

Innovation: Adopting eco-friendly manufacturing processes, such as using recycled materials and optimizing energy usage, alongside developing recyclable or biodegradable coatings, can mitigate the environmental footprint.

Pain Point 4: Cost-Effectiveness

Current Challenge: High production costs often translate into steeper prices for end-users, limiting widespread adoption.

Innovation: Leveraging economies of scale through strategic partnerships and investing in automation technologies can help reduce production costs without compromising on quality. Additionally, offering tiered pricing models based on volume and customization levels can make UV-Blocking Quartz Lighting Tubes more accessible to a broader market.

Conclusion

As the global industrial landscape continues to evolve, UV-Blocking Quartz Lighting Tubes stand as a testament to the intersection of innovation and necessity. By addressing the pressing concerns of our European and American clients, from enhancing durability and customization to promoting environmental sustainability and cost-effectiveness, we pave the way for these advanced materials to flourish in even more diverse applications. By embracing these advancements, we empower industries to reach new heights of precision, efficiency, and safety, ultimately driving progress in a sustainable and forward-thinking manner.