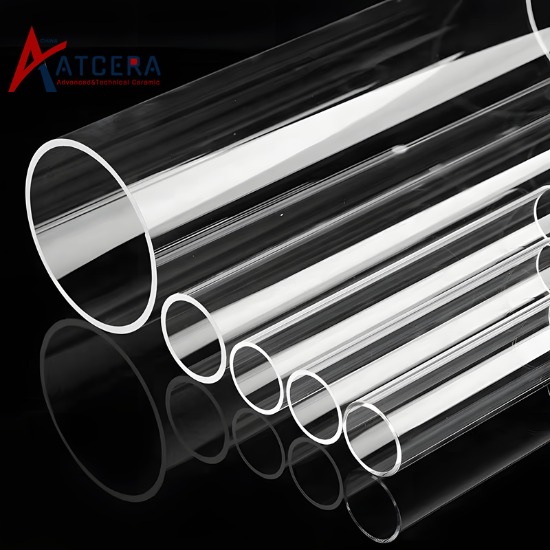

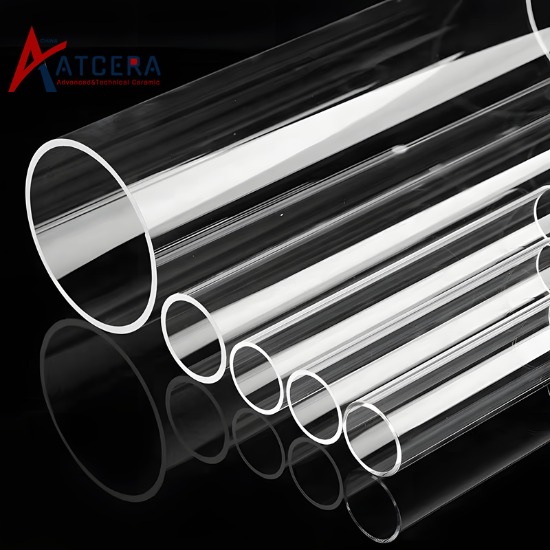

In high-stress environments, durability is essential. When it comes to finding a material that can withstand the toughest conditions while maintaining exceptional performance, quartz tubes are the go-to solution. With their remarkable strength and heat resistance, quartz tubes have become a staple in a wide range of industries, from semiconductor manufacturing to the medical field.

In this ultimate guide, we will delve into the fascinating world of quartz tubes and explore their numerous benefits. We will uncover the secrets behind their exceptional durability and the innovative ways they are enhancing performance in challenging environments.

Whether you are looking to optimize the efficiency of your industrial processes or seeking a reliable material for your scientific experiments, understanding the properties and applications of quartz tubes is paramount. With this comprehensive guide, you will gain invaluable insights into the uses and advantages of these remarkable tubes.

Join us on this journey as we unravel the hidden potential of quartz tubes and discover how they can revolutionize durability in the face of demanding environments.

Properties and characteristics of quartz tubes

Quartz, a naturally occurring crystalline form of silicon dioxide (SiO2), has long been prized for its remarkable properties that make it an exceptional material for a wide range of applications. When it comes to quartz tubes, these unique characteristics are amplified, making them a versatile and indispensable solution in challenging environments.

One of the defining properties of quartz tubes is their exceptional durability. Quartz is an extremely hard and rigid material, with a Mohs hardness of 7, making it highly resistant to scratches, abrasions, and physical damage. This robustness allows quartz tubes to withstand the rigors of demanding industrial and scientific applications without compromising their structural integrity.

Furthermore, quartz tubes exhibit exceptional thermal stability, with a high melting point of around 1,700°C (3,092°F). This remarkable heat resistance enables them to function reliably in high-temperature environments, such as those found in furnaces, kilns, and specialized equipment. The ability to maintain their integrity at elevated temperatures is a crucial advantage, allowing quartz tubes to be utilized in a wide range of applications where thermal stability is paramount.

Benefits of using quartz tubes in challenging environments

The unique properties of quartz tubes make them an invaluable asset in challenging environments, where durability and performance are critical. One of the primary benefits of using quartz tubes is their exceptional resistance to thermal shock. Quartz has a low coefficient of thermal expansion, which means it undergoes minimal dimensional changes in response to rapid temperature fluctuations. This resilience allows quartz tubes to withstand sudden temperature changes without cracking or breaking, making them ideal for applications that involve rapid heating or cooling cycles.

Another significant advantage of quartz tubes is their chemical inertness. Quartz is highly resistant to a wide range of chemicals, including acids, bases, and solvents, making it an ideal choice for use in corrosive or chemically aggressive environments. This chemical stability ensures that quartz tubes maintain their structural integrity and performance even when exposed to harsh chemical conditions, reducing the risk of degradation or failure.

In addition to their thermal and chemical resistance, quartz tubes also exhibit remarkable electrical properties. Quartz is an excellent insulator, with a high electrical resistance that makes it suitable for applications where electrical isolation is crucial. This characteristic is particularly beneficial in the semiconductor industry, where quartz tubes are used in various manufacturing processes to ensure consistent and reliable performance.

Applications of quartz tubes in various industries

The exceptional properties of quartz tubes have made them an indispensable component in a wide range of industries, each with its own unique challenges and requirements.

In the semiconductor industry, quartz pipes play a vital role in the manufacturing of integrated circuits and microchips. They are used as furnace liners, reaction chambers, and substrate holders in processes such as chemical vapor deposition (CVD), thermal oxidation, and diffusion. The thermal stability and chemical inertness of quartz tubes ensure precise control over the delicate semiconductor fabrication environment, enabling the production of high-quality, reliable electronic devices.

The medical and healthcare sectors also rely heavily on the use of quartz glass tubes. These tubes are commonly employed in the production of medical equipment, such as X-ray tubes, electron microscopes, and various diagnostic instruments. Their exceptional durability and resistance to heat and chemicals make them an ideal choice for applications that require sterilization and exposure to harsh environments.

In the energy and power generation industries, quartz tubing find applications in the manufacturing of high-intensity lighting systems, such as those used in UV water purification, phototherapy, and industrial curing processes. The ability of quartz to transmit UV and visible light efficiently, coupled with its thermal stability, makes it a preferred material for these specialized lighting applications.

Factors to consider when selecting quartz tubes

When selecting quartz tubes for use in challenging environments, there are several critical factors to consider to ensure the optimal performance and longevity of the chosen solution.

One of the primary factors to consider is the purity of the quartz material. Quartz tubes can be manufactured from different grades of quartz, each with varying levels of impurities and trace elements. High-purity quartz, with minimal impurities, is essential for applications where precise control over the chemical composition and optical properties of the material is required, such as in semiconductor manufacturing or medical equipment.

Another important factor is the tube's dimensional accuracy and consistency. Precise dimensional tolerances are crucial for applications where the quartz tubes need to fit seamlessly into complex equipment or systems. Variations in the tube's diameter, wall thickness, or length can impact the overall performance and compatibility of the system.

The specific thermal and chemical requirements of the application should also be carefully evaluated when selecting quartz tubes. Different applications may demand different levels of thermal stability, resistance to thermal shock, or tolerance to specific chemicals. Choosing the right quartz tube that meets these specific requirements is essential to ensure reliable performance and extended service life.

Tips for handling and maintaining quartz tubes

Proper handling and maintenance of quartz tubes are crucial to ensuring their long-term durability and optimal performance in challenging environments. By following a few key tips, users can maximize the lifespan and reliability of their quartz tube investments.

One of the most important considerations is handling the tubes with care. Quartz is a brittle material, and sudden impacts or excessive force can lead to cracks, chips, or even complete breakage. When handling quartz tubes, it is essential to use appropriate tools and techniques, such as wearing protective gloves, avoiding direct contact with the tube surfaces, and minimizing any unnecessary handling.

Regular cleaning and maintenance of quartz tubes are also crucial. Depending on the application, quartz tubes may accumulate deposits, residues, or contaminants over time, which can compromise their performance and durability. Implementing a routine cleaning protocol, using appropriate cleaning agents and methods, can help maintain the tubes' pristine condition and prevent premature failure.

Proper storage and transportation of quartz tubes are equally important. Quartz tubes should be stored in a clean, dry environment, protected from physical damage and temperature extremes. When transporting quartz tubes, it is essential to use appropriate packaging and handling methods to minimize the risk of breakage or deformation during the journey.

Common challenges when using quartz tubes and how to overcome them

While quartz tubes are renowned for their exceptional durability and performance, there are some common challenges that users may encounter when working with these specialized materials.

One of the primary challenges is the potential for thermal shock, which can occur when quartz tubes are subjected to rapid temperature changes. Sudden heating or cooling can cause the tubes to crack or shatter, leading to equipment failure and costly downtime. To mitigate this risk, it is crucial to implement proper temperature control and gradual heating/cooling protocols when using quartz tubes in high-temperature environments.

Another challenge is the potential for surface contamination or deposition buildup on the quartz tubes. Depending on the application, various materials may adhere to the tube surfaces, affecting their optical properties, thermal conductivity, or chemical resistance. Regularly scheduled cleaning and maintenance routines, as well as the use of protective coatings or liners, can help prevent or manage these contamination issues.

Additionally, the fragility of quartz tubes can pose a challenge, particularly during installation, removal, or handling. Extreme care must be taken to avoid physical damage to the tubes, which can compromise their structural integrity and performance. Specialized handling tools, protective packaging, and training for personnel can help minimize the risk of breakage or damage during these critical handling processes.

Innovations and advancements in quartz tube technology

The ongoing research and development in the field of quartz tube technology have led to a range of innovative solutions that are continuously enhancing the capabilities and applications of these remarkable materials.

One significant advancement is the development of ultra-high purity quartz tubes. By employing advanced manufacturing techniques and stringent quality control measures, manufacturers are now able to produce quartz tubes with exceptionally low levels of impurities and trace elements. These high-purity quartz tubes are essential for applications in the semiconductor industry, where even the slightest contamination can have a detrimental impact on device performance and yield.

Another innovation in quartz tube technology is the introduction of specialized coatings and surface treatments. These coatings can enhance the thermal, chemical, or optical properties of the quartz tubes, tailoring them to specific application requirements. For example, anti-reflective coatings can improve the light transmission efficiency of quartz tubes used in lighting applications, while protective coatings can enhance the resistance to chemical attack or deposition buildup.

Furthermore, advancements in manufacturing processes have led to the development of quartz tubes with improved dimensional accuracy and consistency. These precisely engineered tubes ensure a perfect fit and seamless integration into complex systems, optimizing the overall performance and reliability of the equipment.

Case studies: Success stories of using quartz tubes in challenging environments

The exceptional properties of quartz tubes have enabled their successful deployment in a wide range of challenging environments, leading to remarkable success stories across various industries.

In the semiconductor industry, a leading chip manufacturer faced a persistent issue of device failures due to contamination in their CVD furnace liners. By switching to high-purity quartz tubes, the company was able to significantly reduce the level of impurities and improve the overall quality of their semiconductor products. This shift not only improved the company's yield but also enhanced the reliability and performance of their devices, solidifying their position as a market leader.

In the medical field, a renowned research hospital was struggling with the sterilization of their electron microscopes, which were critical for advanced diagnostic procedures. The introduction of quartz tubes as the primary material for the microscope components enabled the hospital to effectively sterilize the equipment using high-temperature autoclaving, without compromising the integrity of the delicate instruments. This innovation helped the hospital maintain the highest standards of cleanliness and patient safety, while also improving the efficiency of their diagnostic processes.

In the energy sector, a power generation facility was facing significant downtime due to the frequent failure of their UV water purification lamps. By transitioning to quartz tubes specifically designed for high-intensity UV applications, the facility was able to dramatically improve the lifespan and reliability of their water treatment system. This change not only reduced maintenance costs but also enhanced the facility's overall energy efficiency and environmental sustainability.

Conclusion: The future of quartz tubes in demanding applications

As the demands for durability and performance in challenging environments continue to grow, the role of quartz tubes is set to become increasingly essential. These remarkable materials, with their unparalleled thermal stability, chemical resistance, and structural integrity, are poised to play a pivotal role in driving innovation and pushing the boundaries of what is possible in a wide range of industries.

The ongoing advancements in quartz tube technology, from the development of ultra-high purity variants to the introduction of specialized coatings and surface treatments, are paving the way for even more versatile and tailored solutions. As manufacturers and researchers continue to explore the full potential of quartz tubes, we can expect to see them integrated into increasingly complex and demanding applications, revolutionizing the way we approach challenges in fields such as semiconductor fabrication, medical diagnostics, and energy production.

The future of quartz tubes is undoubtedly bright, as these exceptional materials continue to prove their worth in the face of the most daunting environmental conditions. By harnessing the power of quartz tubes, industries can unlock new levels of efficiency, reliability, and safety, ultimately driving progress and transforming the way we live and work in the modern world.