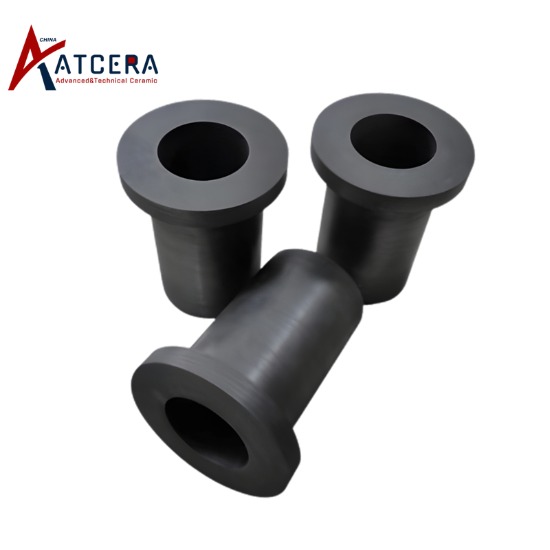

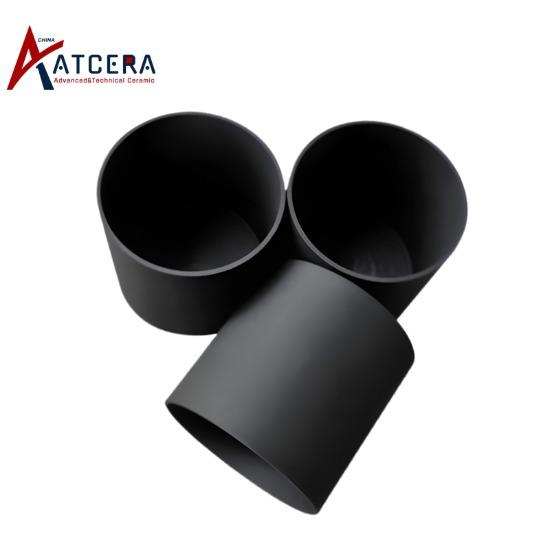

The silicon nitride crucible used in casting is an important vessel in the process of melting and casting, and its performance directly affects the quality of liquid metal and the finished product of castings. In order to ensure the stability and reliability of the silicon nitride crucible in the casting process, it is particularly important to evaluate and characterize the performance of the crucible.

Appearance quality assessment

Appearance quality evaluation is the first step of performance evaluation of silicon nitride crucible. Mainly check whether the surface of the crucible is smooth, there are no obvious defects (such as cracks, sand holes, pores, etc.), and whether the color is uniform. The inner and outer walls of the crucible should be carefully inspected to ensure the overall quality of the crucible.

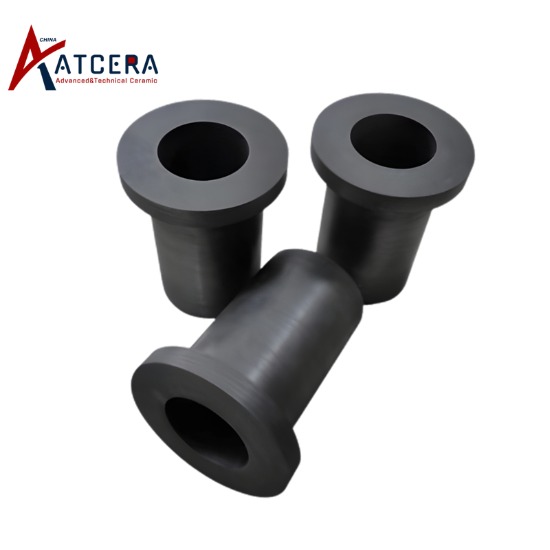

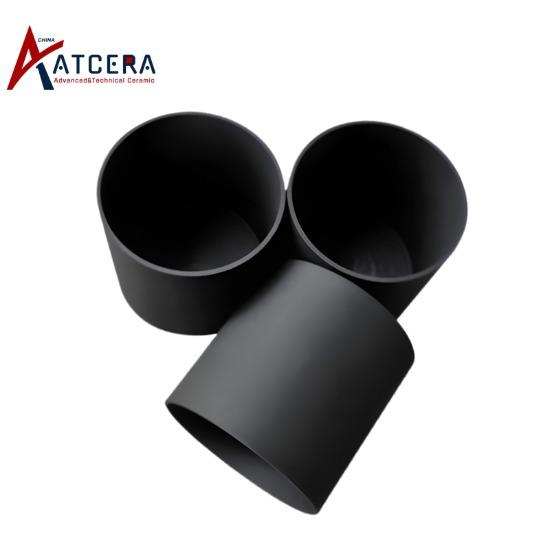

Size detection

The size test mainly evaluates whether the geometric size of the crucible meets the design requirements. Including the crucible diameter, height, wall thickness and other key dimensions. The crucible size is accurately measured by measuring tools (such as calipers, vernier calipers, etc.), and compared with the design drawings to ensure that the crucible size accuracy meets the casting requirements.

Material analysis

Material analysis is the key to evaluate the performance of silicon nitride crucible for melting. The main material and impurity content of crucible were determined by means of chemical composition analysis and metallographic observation. Material analysis can provide important data support for the subsequent performance evaluation of crucible.

Hardness test

The surface hardness of silicon nitride crucible was measured by Vickers hardness tester and Rockwell hardness tester. Through this step, it is possible to evaluate the wear condition and impact resistance of the crucible during use, providing valuable performance data for practical applications.

Density test

The Archimedes principle is used to measure the density. This method precisely measures the mass of the crucible in the air and the mass immersed in water, and then precisely calculates the density of the crucible based on the Archimedes principle.

To sum up, a comprehensive and detailed performance evaluation and characterization of silicon nitride crucible for casting, covering multiple dimensions from appearance quality, dimensional accuracy to material analysis, hardness testing and density testing, is the key to ensure that it plays a stable and reliable role in the melting and casting process. This series of evaluation measures not only help to improve the overall quality of the crucible, but also effectively prevent the quality of the liquid metal and the quality of the finished castings caused by the insufficient performance of the crucible. Through scientific and rigorous performance evaluation, high-quality and high-performance silicon nitride crucible is provided for the casting industry, which further promotes the development and progress of casting technology.