The demand for ultrafine powder materials in modern industry is increasing, especially in high-tech fields such as electronic materials, nanomaterials and the pharmaceutical industry, requiring smaller and smaller particle sizes of powders. What has been confirmed in both theoretical models and experimental validation is that smaller grinding media can provide higher energy density, more shear force and higher impact frequency, thus producing smaller particle size powders more efficiently.

Even the specification of the grinding medium has become an important criterion for evaluating the sand mill, such as the sand mill must be able to provide enough high energy density to promote the small size grinding medium for efficient grinding; Small size grinding medium is more susceptible to wear, so the design level of the sand mill and the material of the cylinder must be able to ensure safe operation for a long time; Whether centrifugal or screen separation, the system must be designed and manufactured with sufficient precision to effectively separate the small grinding medium from the target powder.

The evaluation system of zirconium oxide beads not only has roundness and purity detection, but also includes many tests such as fracture, crushing, aging and water grinding. The water grinding test mainly simulates the wear condition of zirconia beads in the actual working environment to evaluate the wear resistance, evaluate the physical properties and chemical stability of zr2o beads in water for a long time, and infer its service life. ATCERA broke through the pure water grinding test and began to introduce water clarified zirconium oxide beads in 2022, achieving satisfactory test results with many customers.

Examples of test conditions:

1) Laboratory sander, 2300rpm, grinding for 15 hours, testing 0.05mm, 0.1mm, 0.3mm zirconia beads, water to keep clear;

2) High-speed shaker, 24 hours, test 0.05mm, 0.1mm zirconia beads, water to keep clear.

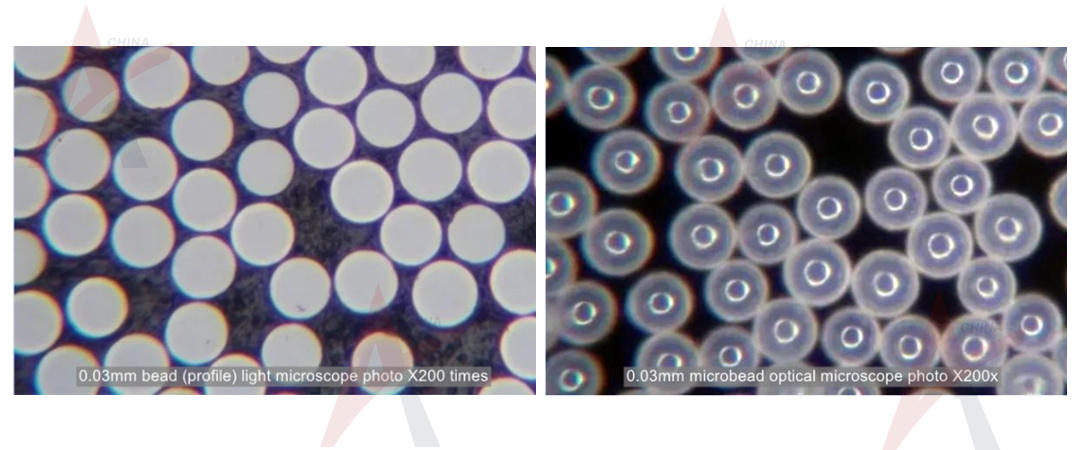

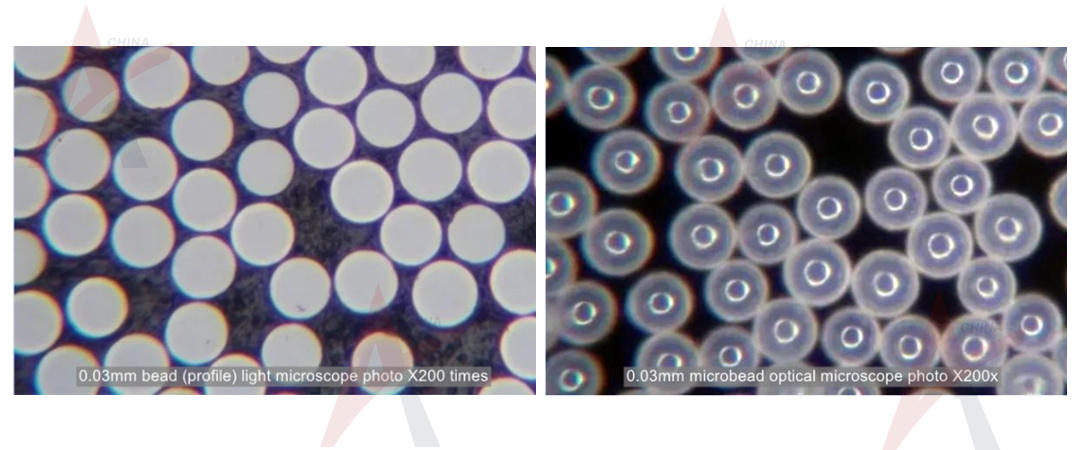

After years of continuous research and development, ATCERA has developed advanced microbead production technology, using high-quality yttrium-stabilized zirconia powder as raw materials, and strictly controlling each process of production to produce the final zirconia bead product. The inside of the product is dense and uniform, the surface is smooth, the particle size distribution is narrow, and the batch quality is stable. In 2015, the company began to supply high-performance microbeads in batches of 0.05mm, 0.1mm and larger specifications, and can produce high-performance zirconia microbeads up to 0.03mm.

Wet ultrafine grinding is an effective method to prepare nano and submicron materials. Sand mill and zirconium oxide beads are widely used in lithium electric materials, ceramic materials, coatings and other fields. ATCERA's main products include yttrium stabilized zirconia beads, cerium stabilized zirconia beads, zirconium silicate beads, zirconium toughened alumina beads, etc., and has a professional ceramic materials R & D team, familiar with powder production technology, various ceramic bead properties and applications, wet grinding theory and practice.