In the ever-evolving landscape of the semiconductor industry, advancements in materials science are pivotal to unlocking new horizons in performance, durability, and precision. Among these groundbreaking developments, Optical Grade Quartz Tubes stand as a testament to the fusion of cutting-edge technology and material purity. This article delves into the myriad advantages, applications, challenges, innovations, and future prospects of Optical Grade Quartz Tubes, emphasizing their pivotal role in revolutionizing the advanced semiconductor sector.

Advantages of Optical Grade Quartz Tubes

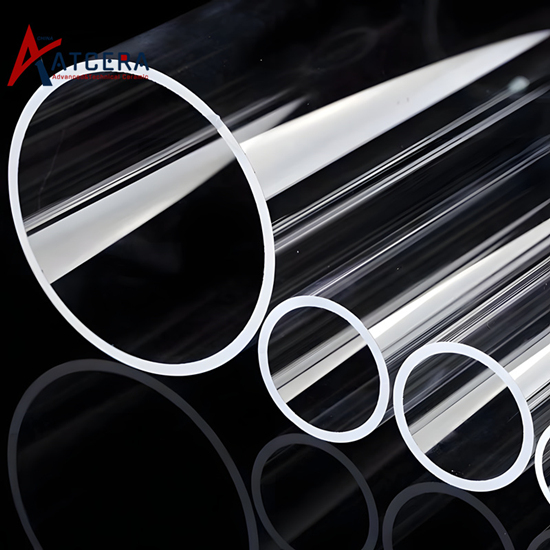

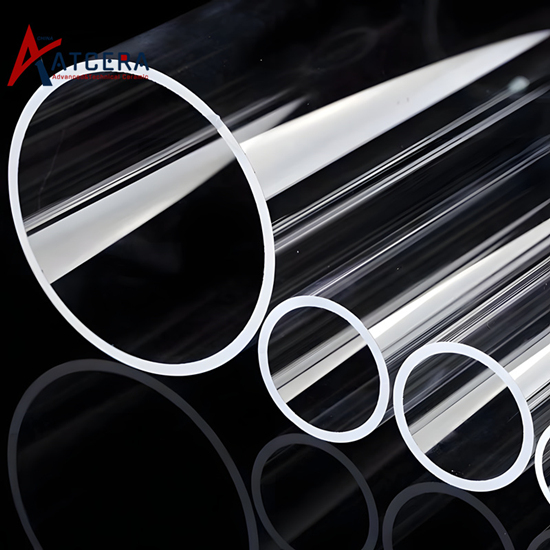

Optical Grade Quartz Tubes, crafted from ultra-pure and meticulously processed quartz, boast an unparalleled combination of properties that make them indispensable in high-tech applications. Their exceptional optical clarity, high thermal stability, and low coefficient of thermal expansion ensure precise control over temperature fluctuations, minimizing distortion and enhancing process accuracy. Furthermore, their resistance to chemical corrosion and radiation damage underscores their durability in harsh environments, making them ideal for demanding semiconductor manufacturing processes.

Applications of Optical Grade Quartz Tubes

The versatility of Optical Grade Quartz Tubes spans multiple facets of the semiconductor industry. They are instrumental in wafer etching and deposition chambers, where their purity ensures minimal contamination during critical fabrication stages. Additionally, their use in optical components, such as windows and lenses, enhances the efficiency of photolithography processes by enabling precise light transmission. Their integration into furnaces and reactors facilitates temperature-sensitive synthesis reactions, underpinning the production of advanced materials for semiconductor devices.

The Role of Optical Grade Quartz Tubes in Advanced Semiconductor

In the realm of advanced semiconductors, Optical Grade Quartz Tubes are instrumental in pushing the boundaries of miniaturization and performance. Their ability to withstand extreme temperatures while maintaining structural integrity is crucial for the development of next-generation microchips, where even the slightest deviation can compromise functionality. As semiconductor geometries shrink and processing complexities escalate, the reliance on Optical Grade Quartz Tubes grows, ensuring the precision and reliability required for cutting-edge technology.

Challenges in Utilizing Optical Grade Quartz Tubes

Despite their numerous advantages, the utilization of High-Purity Optical Quartz Tubing presents challenges, notably in terms of cost and availability. The stringent requirements for purity and precision drive up production costs, while maintaining a consistent supply chain can be daunting due to the rarity and complexity of raw materials. Additionally, integrating these tubes into advanced manufacturing processes often necessitates specialized equipment and expertise, posing barriers to entry for some manufacturers.

Innovations and Research in Optical Grade Quartz Tubes

Ongoing research and development efforts focus on enhancing the properties of Precision Grade Optical Quartz Tubes further, aiming to reduce costs, improve production efficiency, and expand their applicability. Advances in nanotechnology and precision engineering are enabling the creation of thinner, stronger, and more optically transparent tubes. Moreover, the exploration of alternative quartz sources and recycling strategies aims to mitigate supply chain constraints and environmental impacts.

Manufacturing and Production of Optical Grade Quartz Tubes

The manufacturing process of Optical Grade Quartz Tubes is meticulous, involving the purification of raw quartz to ultra-high purity levels, by precise shaping and polishing. Advanced manufacturing techniques, such as chemical vapor deposition and plasma-assisted processes, enable the creation of complex structures with unparalleled surface quality. Stringent quality control measures ensure that every tube meets the rigorous standards demanded by the semiconductor industry.

Future Prospects of Optical Grade Quartz Tubes in Advanced Semiconductor

Looking ahead, Optical Grade Quartz Tubes hold immense promise for advancing the semiconductor industry. As Moore's Law approaches its physical limits, the need for innovative materials and processes intensifies. Optical Grade Quartz Tubes, with their unique combination of properties, are poised to play a pivotal role in enabling the development of smaller, faster, and more energy-efficient semiconductor devices. Their integration into emerging technologies, such as 3D printing for semiconductor manufacturing, will further accelerate this progression.

Comparison with Other Semiconductor Materials

While other materials, such as silicon carbide and alumina, offer their own sets of advantages in semiconductor applications, Optical Grade Quartz Tubes stand out for their unparalleled optical clarity, thermal stability, and chemical resistance. These properties, coupled with their ability to withstand extreme processing conditions, make them invaluable for tasks that require a higher degree of precision and control.

Conclusion: The Potential of Optical Grade Quartz Tubes in Revolutionizing the Semiconductor Industry

In conclusion, Optical Grade Quartz Tubes represent a pivotal innovation in the semiconductor industry, with the power to propel technological advancements forward. Their unique blend of properties, coupled with ongoing research and development, positions them as essential components in the pursuit of next-generation microchips and devices.