In the ever-evolving landscape of industrial technology, alumina ceramic valves have emerged as a pivotal component, revolutionizing the way we control fluid flow in various applications. As an industrial ceramic engineer with decades of experience in Europe and the Americas, I've witnessed the immense potential of these valves and their growing demand among industries globally. This article aims to provide a comprehensive overview of alumina ceramic valves, highlighting their unique characteristics, applications, selection criteria, manufacturing process, and success stories.

Characteristics of Alumina Ceramic Valves

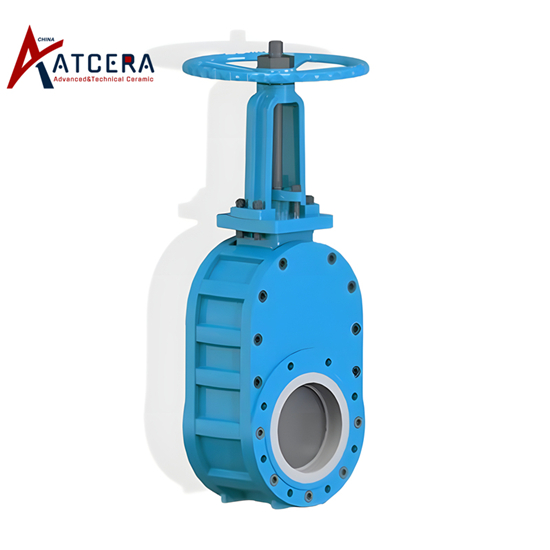

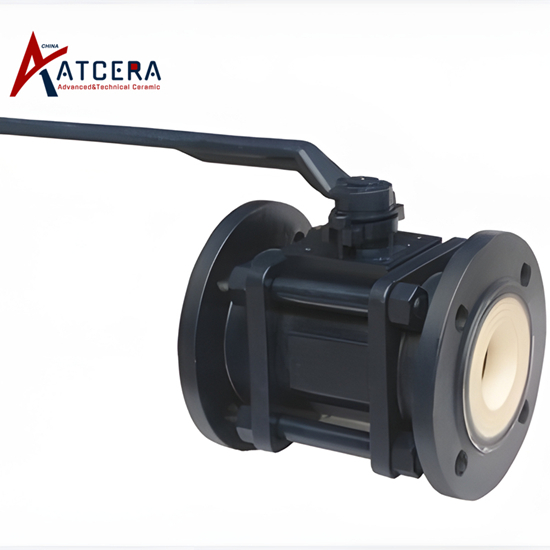

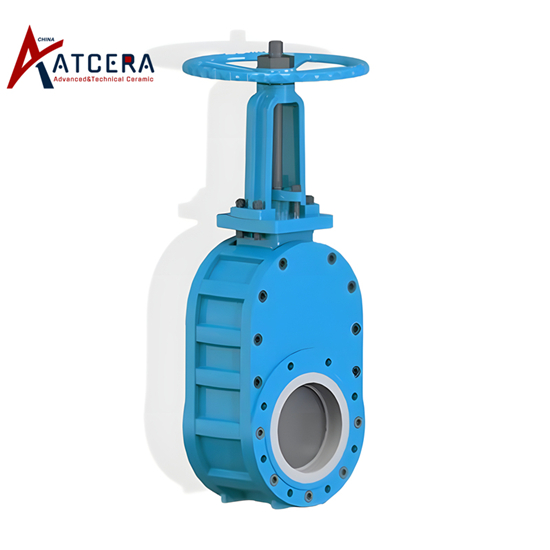

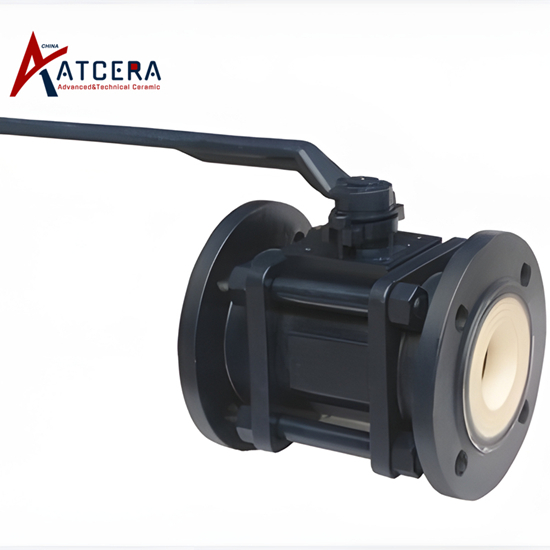

Alumina ceramic valves are renowned for their exceptional properties. They are crafted from high-purity alumina powder, a material renowned for its superior hardness, wear resistance, and corrosion resistance. These valves exhibit high strength, ensuring durability and reliability in even the most demanding environments. Moreover, alumina ceramic valves are inherently inert, eliminating the risk of contamination or chemical reactions with the fluids they handle.

Application Fields of Alumina Ceramic Valves

The versatility of alumina ceramic valves is unparalleled, finding applications across diverse industries. In mechanical engineering, they are indispensable for controlling fluid flow and direction in hydraulic, lubricating oil, fuel, and air conditioning refrigerant systems. In the petrochemical industry, alumina ceramic valves are ideal for handling crude oil, refined oil, and chemical liquids due to their excellent corrosion resistance. Pharmaceutical and biological processes also benefit from the inert nature and non-polluting properties of alumina valves. Additionally, their high temperature resistance makes them a suitable choice for steam flow control in power stations.

How to Select the Right Alumina Ceramic Valve for Your Project

Choosing the right alumina ceramic valve for your project is crucial. Consider factors such as the fluid properties, operating conditions, and specific requirements of your application. Look for valves that are specifically designed for your industry and comply with relevant standards and regulations. It's also essential to select a trusted manufacturer with a proven track record in producing high-quality alumina ceramic valves.

Manufacturing Process of Alumina Ceramic Valves

The manufacturing process of alumina ceramic valves involves precision engineering and advanced technologies. High-purity alumina powder is first processed into a dense and homogeneous body. This body is then shaped into the desired valve design using precision machining techniques. The final step involves firing the valve at high temperatures to achieve the desired mechanical and chemical properties. The result is a robust and reliable valve that can withstand the toughest operating conditions.

Case Studies and Success Stories of Using Alumina Ceramic Valves

Numerous case studies and success stories demonstrate the effectiveness of alumina ceramic valves in various applications. For instance, in a petrochemical plant, alumina ceramic valves were used to control the flow of crude oil and chemicals. Due to their excellent corrosion resistance, these valves performed flawlessly, ensuring uninterrupted operation and reducing maintenance costs. Similarly, in a pharmaceutical manufacturing facility, alumina ceramic valves were used to control the liquid flow in drug production processes. Their inert nature and non-polluting properties ensured the purity and safety of the final product.

Conclusion

In conclusion, alumina ceramic valves are a game-changer in modern industries. Their superior properties, including high strength, wear resistance, corrosion resistance, and inert nature, make them ideal for controlling fluid flow in various applications. Whether it's mechanical engineering, petrochemical, pharmaceutical, or power generation, alumina ceramic valves are the smart choice for ensuring reliable and efficient operation. As an experienced industrial ceramic engineer, I highly recommend considering alumina ceramic valves for your projects.