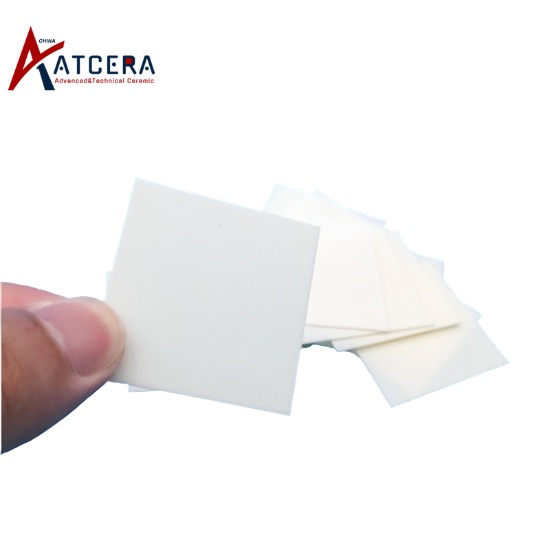

With the rapid development of modern electronic technology, the design of microwave RF components and high-frequency circuits is becoming more and more complex, and the performance requirements of components are becoming higher and higher. In order to meet these needs, thin film technology, as an advanced microelectronic technology, plays an increasingly important role in the design of microwave components and high-frequency circuits. This article introduces several thin film components based on alumina substrate design, including thin film attenuators, thin film couplers, thin film Bridges, thin film resistors, and thin film capacitors. These components play an indispensable role in microwave RF components and high-frequency circuits with their unique properties and wide application fields.

1 Film attenuator

The design of thin film attenuator using alumina ceramic substrate is often used for large signal attenuation in microwave RF module, or for multi-stage adjustment of attenuation value in programmed attenuation circuit. It is also based on the reasonable design of the square resistance of tantalum nitride film layer and the film process design of alumina ceramic circuit. Thin film attenuators can achieve high flatness of attenuation value in ultra-wide band with stable performance.

2 Thin film coupler

Aluminum oxide ceramic substrate design film coupler, often used in microwave component system power detection or signal separation, can be designed into any weak coupling degree coupler, and can use tantalum nitride design integrated isolation load, the port can be designed into the form of surface paste package, directly welded in the circuit for work. It can be designed into a multi-stage form when it needs to be applied to a wide band.

3 Film bridge

The use of alumina ceramic substrate design film bridge, also called 3dB bridge, often used to separate the signal and make it have a 90° or 180° phase difference, lange bridge is a form of its application more, through the gold wire bonding to achieve the signal connection between the lines.

4 Thin film resistance

The use of alumina ceramic substrate design film resistor, often used in high-precision, low noise and high stability of the circuit, often integrated in the microstrip film circuit design and processing, can also be designed separately into a variety of resistance types of film resistor used, or designed into a resistance network, through the gold wire bonding to select the required resistance value.

5 Thin film capacitance

The thin-film capacitor is designed with alumina ceramic substrate, which is often used in high-frequency filtering. The thin-film capacitor with arbitrary capacitance can be designed for power supply. The performance is more stable than that of ordinary chip capacitor, and it is suitable for high-frequency circuit.

In summary, thin-film components designed on alumina ceramic substrates, such as thin film attenuators, thin film couplers, thin film Bridges, thin film resistors and thin film capacitors, have shown excellent performance and wide application prospects in microwave RF components and high-frequency circuits. These components not only have the advantages of high precision, low noise and high stability, but also can achieve high performance indicators in the ultra-wide band, which provides a strong support for the development of modern electronic technology. With the advancement of science and technology and the improvement of demand, thin film technology will continue to play a more important role in the design of microwave RF components and high-frequency circuits, and promote the continuous development and innovation of electronic technology.