With the rapid development of modern electronic technology, the requirements of RF and microwave electronics industry for substrate materials are increasing day by day. Alumina substrate has become one of the most concerned materials in this field because of its unique physical and chemical properties. This paper will study it in detail from many aspects.

Application advantages of alumina ceramic substrate

The application advantages of alumina substrate in the RF microwave electronics industry are mainly reflected in the following aspects:

High dielectric constant

The alumina ceramic substrate has a high dielectric constant, which allows the circuit to be miniaturized while maintaining high performance. This feature is particularly important in today's pursuit of miniaturization and integration of electronic components.

Good thermal stability

The alumina ceramic substrate has good thermal stability, small temperature bleaching, and can maintain stable electrical properties in a wide temperature range, which is essential to ensure the reliability of RF microwave components.

High strength and chemical stability

The alumina ceramic substrate has high strength and chemical stability, which can resist the erosion of various chemical substances and extend the service life of the component.

Wide range of applications

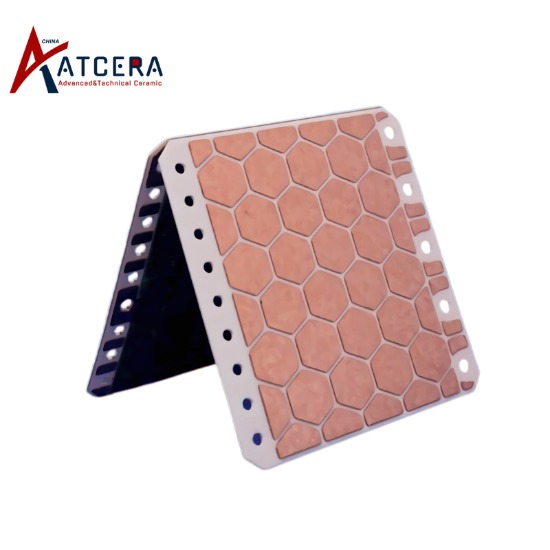

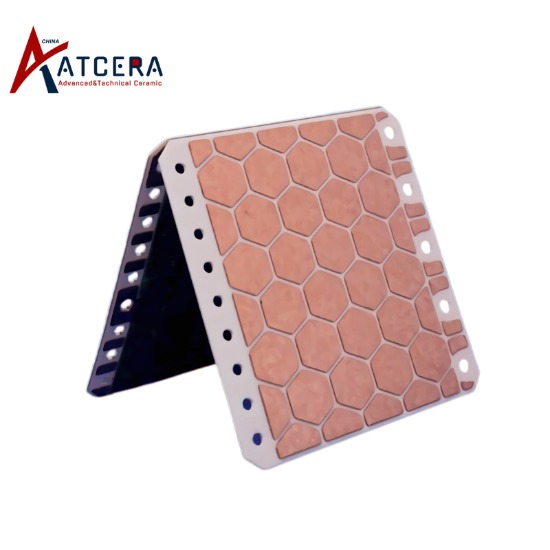

alumina ceramic substrate can be used in all kinds of thick film circuit, film circuit, hybrid circuit and microwave module, etc., showing its wide applicability.

The processing accuracy of alumina ceramic substrate

The alumina ceramic substrate can be used for circuit machining based on the thin film lithography process, and its accuracy can reach the micron level. This high-precision machining technology enables alumina ceramic substrates to be used to manufacture a variety of precision passive devices. Because its dielectric constant is higher than that of the general PCB substrate, the size of the device designed is smaller, which further promotes the miniaturization of various component modules.

The purity classification of alumina ceramic substrate and its effect on performance

Alumina ceramic substrate can be divided into 90 porcelain, 96 porcelain, 99 porcelain and other different models according to purity. The main difference is the difference in the amount of substrate doping, the less the amount of doping, the higher the purity of the substrate.

Alumina ceramic substrates of different purity show certain differences in electrical and mechanical properties:

Electrical properties

The higher the purity of alumina ceramic sheet, the higher the dielectric constant, the lower the dielectric loss. For example, at a frequency of 1MHz, the dielectric constant of an alumina ceramic sheet with a purity of 99.6% is 9.9, while the dielectric constant of an alumina ceramic substrate with a purity of 96% is 9.6. Although the difference between the two permittivity is only a few tenths, in microwave RF design, this small difference is enough to cause significant changes in the electrical performance of the device.

Mechanical properties

The higher the purity of the alumina ceramic substrate, the higher the strength and hardness, and the better able to withstand external stress and impact.

Finish

The high purity alumina ceramic substrate surface finish is better, which is conducive to improving the accuracy and reliability of circuit processing.

However, it is worth noting that the higher the purity of the alumina ceramic substrate, the price is also relatively high. Therefore, when choosing substrate materials, trade-offs need to be made according to specific application needs and cost budgets.

In summary, alumina ceramic substrates in the RF microwave electronics industry has significant application advantages, high-precision processing capabilities and a variety of purity classification. Its unique physical and chemical properties make alumina ceramic substrates one of the indispensable materials in this field. In the future, with the continuous progress of science and technology and the changing application needs, alumina ceramic substrates are expected to show their unique advantages and application value in more fields.