Ceramic heaters are mainly divided into two types: alumina and silicon nitride, with the following characteristics:

1. Miniaturization, light weight, and power saving; capable of achieving high power density and high thermal efficiency, allowing for the installation of heating elements with various capacities simultaneously.

2. Excellent thermal characteristics, demonstrated by fast heating rates and the ability to achieve any temperature distribution.

3. High safety and reliability, reflected in good electrical insulation performance and voltage resistance characteristics, with heating resistance not oxidizing, minimal disconnection and aging, and good corrosion resistance.

4. Wide application, capable of heating liquids such as water and kerosene, as well as solids like metals.

5. Environmentally friendly, with no pollution or noise.

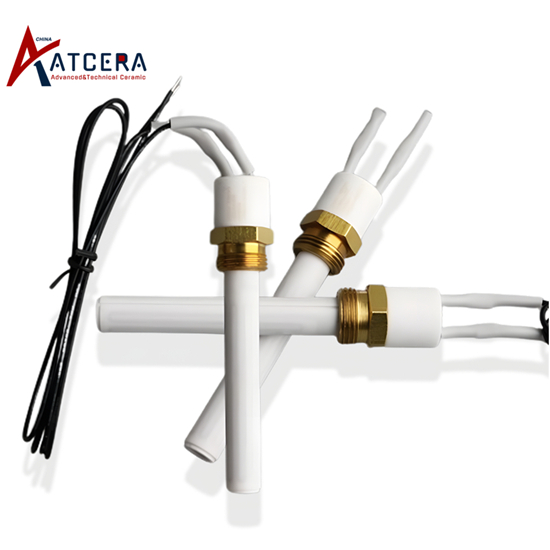

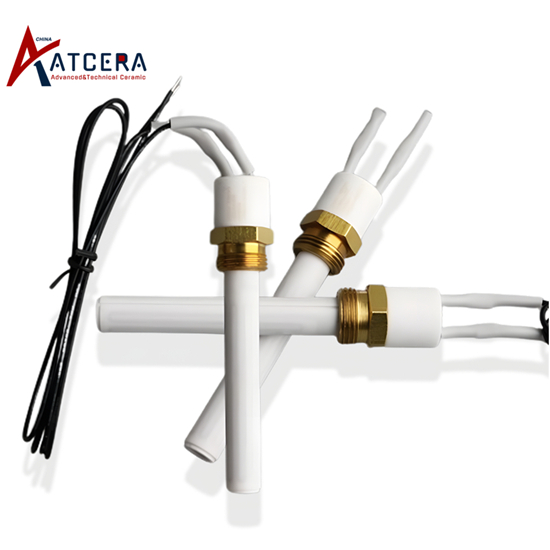

Types and basic structure of ceramic heaters: The ceramic heating resistance material (resistance film, resistance sheet, or resistance wire) is embedded in alumina or silicon nitride ceramics. The heating resistance material and ceramic green body can be integrated through co-firing (simultaneous firing), completely isolating it from external air, with the ceramic heating body providing protection and insulation.

The high-temperature co-firing of alumina ceramic heating elements involves directly printing resistance paste on the alumina ceramic green body. After lamination and debinding, it is co-fired at a high temperature of around 1600°C to form an integrated medium-low temperature heating element. The resistance paste is usually tungsten-based and is formed into a printed circuit on the alumina ceramic green body through screen printing, resulting in a heating thick film circuit after co-firing. Therefore, the performance of tungsten thick film paste is particularly important. The tungsten thick film paste should consist of three parts: functional phase, organic vehicle, and inorganic binder. The functional phase is tungsten particles, providing conductivity; the organic vehicle mainly forms a suspension and adjusts the paste viscosity; the inorganic binder ensures that after co-firing, the tungsten particles are firmly bonded to the substrate, forming a continuous phase.

Silicon nitride heating elements usually involve placing tungsten wire or printing other resistance paste within the silicon nitride formed body. A new type of flat heating element is made by pressing a mixture of heating resistance powder and silicon nitride powder, then co-firing at around 1750°C in a pressure sintering furnace under nitrogen pressure, resulting in an integrated silicon nitride heating element.

Ceramic heaters have a simple design, fast heating, high reliability, good safety, and excellent characteristics such as corrosion resistance, high temperature resistance, long life, high efficiency, energy saving, uniform temperature, and good thermal conductivity, making them widely used in automotive, petroleum, industrial, medical, semiconductor, and household appliance fields.

In diesel engines, ceramic heaters are used as starting aid glow plugs, employing silicon nitride heating elements with fast heating and excellent durability at high temperatures, resulting in cleaner exhaust emissions immediately after starting.

In automotive heating elements, such as auxiliary heaters for vehicles in cold regions, silicon nitride heating elements can quickly vaporize, ignite, and burn fuel. This allows for rapid heating of the car interior shortly after engine start and during idling stops.

As ceramic heating elements for oxygen sensors, ceramic heaters are used in oxygen sensors for exhaust gas detection in cars. Most gasoline engine cars are equipped with these heating elements. Due to their fast heating, they enhance sensor sensitivity during the low exhaust temperature phase right after engine start, helping to reduce exhaust emissions.

In the petroleum and gas equipment field, ceramic heaters are used as ignition heating elements. In kerosene heaters and gas stoves, they provide a stable ignition effect without the discharge sound and electrical noise of high-voltage spark ignition, and a larger heating area.

For vaporization and combustion heating elements, ceramic heaters, such as alumina heating elements in kerosene warm-air heaters, fully exploit their small size, high output, and fast heating characteristics, enabling the miniaturization of vaporization devices and shortening vaporization time.

ATCERA can produce ceramic heating elements, if need to get more information or any customized demand, please visit www.atcera.com or send email to info@atcera.com.