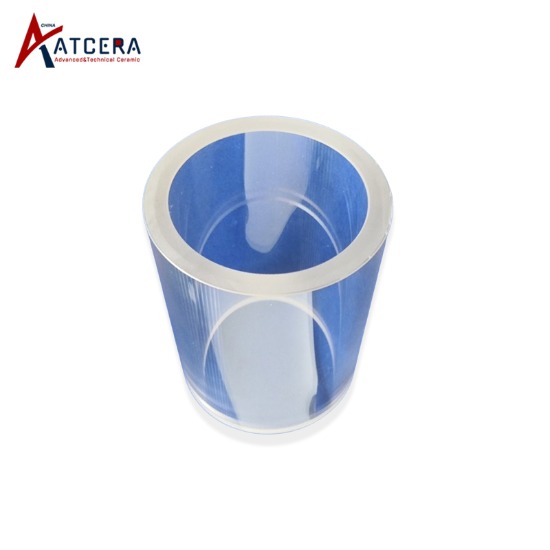

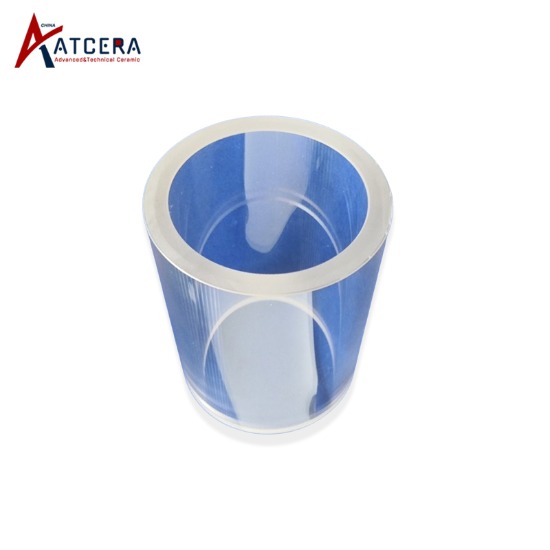

As a kind of high performance material, transparent ceramics show great application potential in the fields of optical window, laser medium and high temperature wave transmittance materials because of its unique optical transparency and excellent mechanical properties. Among the many methods of preparing transparent ceramics, vacuum sintering technology has become one of the most widely researched and applied methods with its unique advantages. In this paper, the principle, characteristics and application of vacuum sintering technology in the preparation of transparent ceramics are discussed in order to provide theoretical reference and practical guidance for the research and development of transparent ceramic materials.

Basic principle and mechanism of vacuum sintering

Vacuum sintering refers to the method of heating the ceramic body in a complete or partial vacuum environment to reach the sintering temperature and complete the densification process. The vacuum environment creates the internal and external pressure difference, promotes the effective discharge of pores, significantly reduces the porosity of ceramics, and promotes the growth of grains, forming a high density microstructure. In addition, the vacuum condition effectively inhibits the decomposition and element volatilization of ceramic materials at high temperatures, ensuring the chemical stability of the materials.

Advantages of vacuum sintering technology

Compared with other sintering methods, vacuum sintering has remarkable operation simplicity, cost effectiveness and production efficiency. No need for complex pressure control system, reducing equipment cost and maintenance difficulty; At the same time, because the vacuum environment accelerates the process of pore elimination and grain growth, the sintering cycle is shortened, and the production efficiency is improved. These advantages make vacuum sintering the preferred technology for large-scale industrial production of transparent ceramics.

Application of vacuum sintering in the preparation of transparent ceramics

Many kinds of oxide based ceramics, especially rare earth activated Yttrium aluminum garnet (YAG), Yttrium oxide (Y₂O₃) and alumina (Al₂O₃), have been successfully prepared by vacuum sintering technology of high quality transparent ceramics. These materials not only have excellent light transmission properties, but also show good thermal stability and mechanical strength, and are widely used in solid state lasers, optical lenses, high temperature sensors and other fields, promoting the rapid development of related technologies.

In summary, vacuum sintering technology plays an important role in the preparation of transparent ceramics due to its unique sintering mechanism, significant cost effectiveness and wide application prospects. With the continuous progress of material science and the continuous optimization of preparation technology, vacuum sintering technology is expected to show greater potential in the preparation of more types of transparent ceramic materials, further broaden the application field of transparent ceramics, and inject new vitality into the development of high-tech industry. In the future, in-depth study of the microscopic mechanism in the vacuum sintering process and exploration of more efficient sintering process parameters will be the key direction to promote the performance of transparent ceramic materials and expand its application range.