Alumina tray is an important industrial calcination vehicle, the material has excellent chemical stability, can be used in corrosive chemical media environment, acid, alkali and organic solvents have strong corrosion resistance. Alumina tray is an excellent electrical insulation material with good insulation and dielectric properties, which can prevent the flow of current and effectively prevent the loss of electric heat and waste of electric energy.

Special Tray for negative poles

The al2o3 tray is deep cylindrical shape, the product surface finish is high, the strength is high, the slag is not polluted to the product, especially suitable for automatic loading and unloading operation, the loading amount is large, to meet the continuous operation of vacuum pumping, not only energy saving, but also to avoid the tray handling, low labor intensity, the work site is clean, and the product purity is high.

Industry custom tray is the result of deep cooperation and two-way travel with users, compared with general tray, in improving production efficiency, ensuring product quality, reducing labor intensity has been strengthened. It can be used for pre-carbonization of negative electrode materials, calcination of powder materials such as non-caking α-alumina, activated carbon and quartz powder.

Special ceramic waxing Tray

This kind of tray has square, round tray, can be customized according to product size, high surface finish, flat bottom, moderate porosity, low iron content, especially suitable for industrial ceramic wax removal process.

Hot die casting alumina ceramics, talc porcelain wax, rare earth, kaolin calcination, there are many common requirements for the tray, in addition to the general tray requirements of high temperature resistance, but also include high air tight requirements, to maintain a stable calcination environment, high finish in addition to avoiding surface defects, but also beneficial to impurity and particle control.

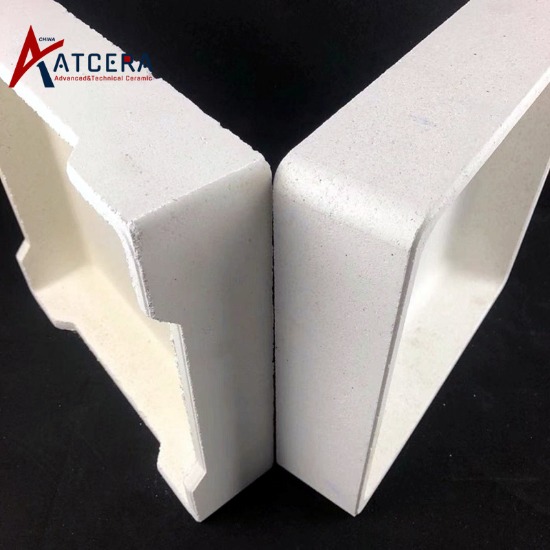

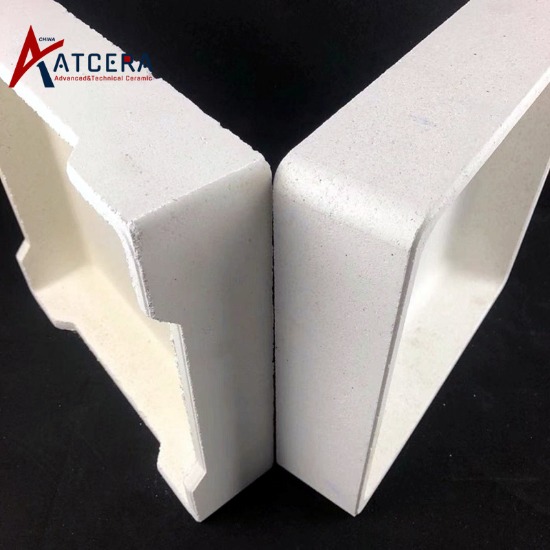

Special Tray for magnetic materials

This kind of square tray has high surface finish, high strength, no slagging, good chemical stability, flat bottom, high thermal conductivity, long life, especially suitable for magnetic materials, electronic ceramics, and widely used in industrial ceramics, electronic ceramics and magnetic materials firing.

In summary, as an indispensable key vehicle for industrial calcination, the tray's material characteristics and design innovation play an important role in improving production efficiency, ensuring product quality, and reducing energy consumption and labor intensity. Custom saggs for special applications, such as cathode materials, ceramic wax removal or magnetic materials, have demonstrated excellent corrosion resistance, electrical insulation, high thermal conductivity and long life characteristics to meet the high standards of calcination processes in different industries. In the future, with the continuous progress of material science and the in-depth development of intelligent manufacturing, the performance and application range of tray will be further expanded, bringing more possibilities to the field of industrial calcining.