Alumina tray is an industrial appliance made of alumina material. The raw material of alumina tray is mainly high-purity alumina powder, of which some products such as 99 alumina tray have alumina content of more than 99%. Alumina tray has excellent high temperature resistance and can work stably in high temperature environment for a long time. Its melting point is as high as 2072 degrees Celsius, and some products such as alumina crucible can be used at 1650 degrees Celsius for a long time, and the short-term use temperature can reach 1800 degrees Celsius.

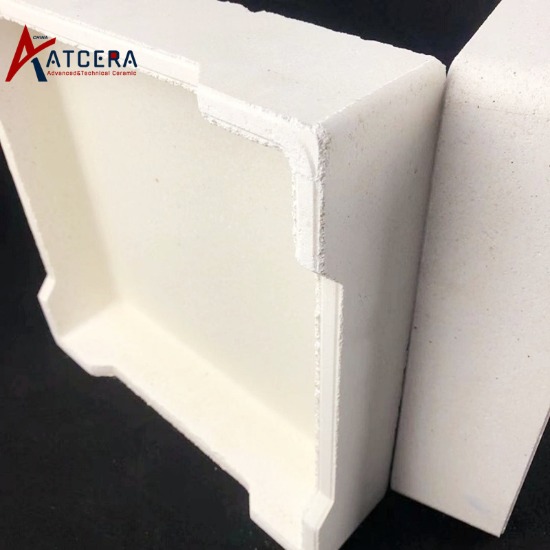

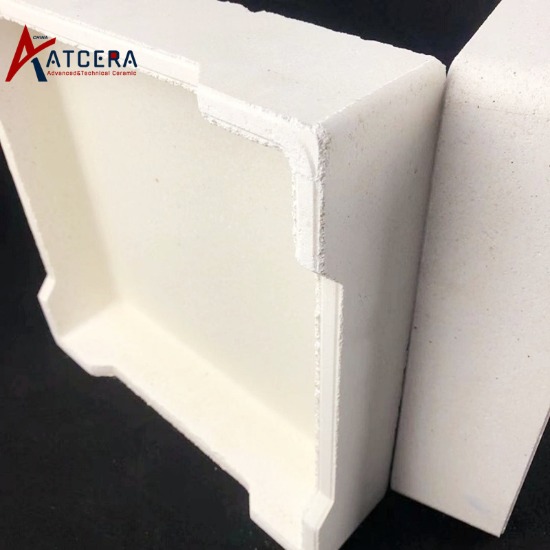

Alumina Calcining Special Tray

This kind of tray is preferably made of clay and high aluminum materials, and is prepared by materials selection, homogenization, iron removal, mixing, aging, drying, calcining and other processes. The product has good uniformity, low iron content, main crystalline phase is mullite phase, excellent high temperature performance, high product strength, not easy to drop slag, and has good resistance to mineralization agent erosion, which is very suitable for calcining α-alumina in tunnel kiln. Alumina adhesion less, long service life.

The difference in iron oxide content, for example, may lead to changes in the color of alumina products, changes in crystal phase composition or changes in thermal properties; The difference in density of the tray. for example, will affect the thermal conductivity, mechanical strength, and coefficient of thermal expansion of the tray. Ceramic grade, refractory grade, abrasive grade, high proportion of mineralized calcined alumina products and other different applications can be selected according to industry sensitivity, product segmentation can help users improve product quality, ensure the stability and controllability of the calcination process.

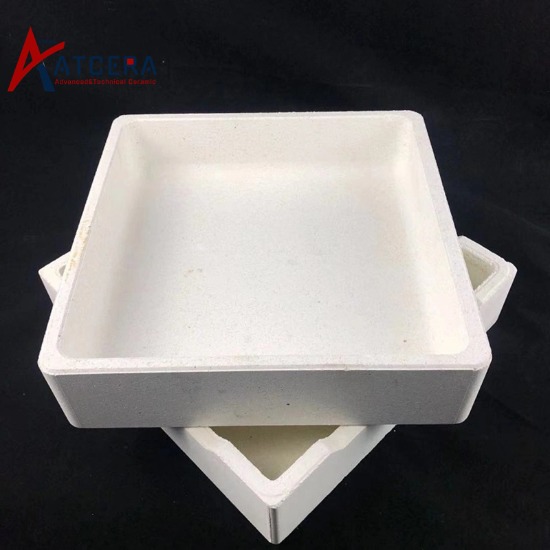

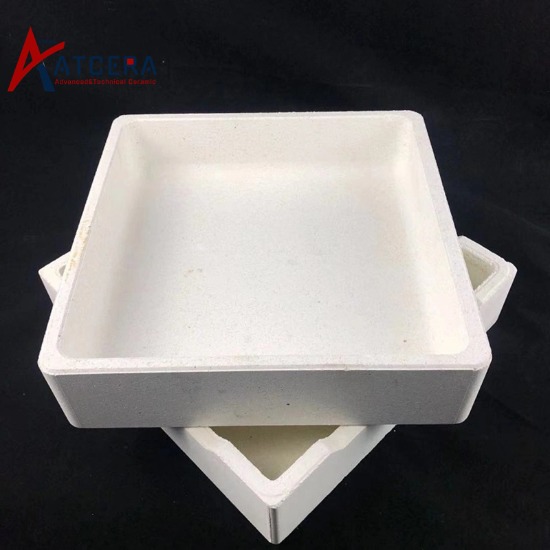

Abrasives, Abrasives, Grinding Balls, Special Tray for Calcination of Ceramic Pigments

This kind of tray scientific formula, strict process control, iron content is low to less than 1%, high surface finish, high strength, not easy to drop slag, and low coefficient of thermal expansion, good thermal shock resistance, no pollution to products.

Iron impurities are common, but also deadly for some applications, such as even a small amount of iron can greatly reduce the hardness and wear resistance of abrasives, molds, and grinding balls; For example, iron impurities can cause product color deviation and affect the appearance, and ceramic colors are very sensitive to this. The tray is suitable for applications with higher iron content requirements.

Cordierite Combined Mullite Tray (High Purity Powder)

This kind of tray is made of cordierite combined with mullite, and the product has good thermal shock resistance, high surface finish, no slag, low iron content, stable chemical properties, and no pollution products, especially suitable for high purity powder burning.

Cordierite and mullite have many similar characteristics, such as excellent high temperature resistance, good wear resistance and corrosion resistance, are both chemically stable materials, and have good processing properties, can be prepared regular shape, accurate size tray products. The above characteristics make it outstanding in applications such as aluminum hydroxide, ultrafine aluminum oxide, lithium battery cathode materials and other high-purity powders containing crystal water.

To sum up, as an important auxiliary tool in the industrial field, alumina tray plays an irreplaceable role in alumina calcination, abrasives manufacturing, ceramic color treatment and high purity powder burning by virtue of its excellent high temperature resistance, good mechanical strength, low iron content and corrosion resistance of mineralizer. Different kinds of alumina tray meet the high standard requirements of product quality, production efficiency and cost control in different industries through fine raw material selection and advanced manufacturing process, and provide solid technical support for the development of modern industry.