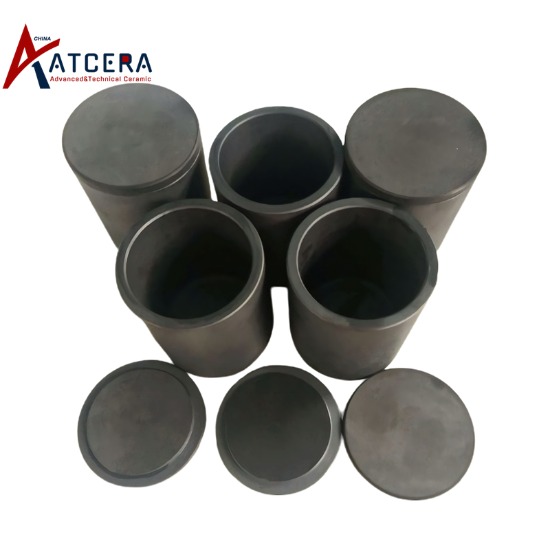

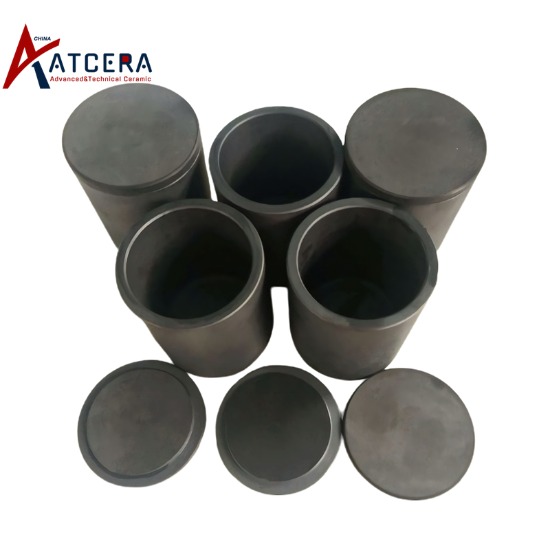

With the continuous progress of ceramic materials science and technology, silicon carbide (SiC), as a class of high-performance non-oxide ceramic materials, has shown great application potential in many industrial fields because of its unique physical and chemical properties. Especially in high temperature kilns, silicon carbide crucible, with its excellent high temperature resistance, corrosion resistance and high thermal conductivity characteristics, has become a key component for bearing and protecting the high temperature sintering process. The purpose of this paper is to investigate the material composition of sic crucible, analyze the characteristics of its core material, and examine how auxiliary materials work together to optimize the overall performance of the crucible.

Characteristics of silicon carbide core material

1. High hardness and wear resistance: the hardness of silicon carbide is second only to diamond, which gives the crucible excellent wear resistance and effectively extends the service life.

2. Excellent corrosion resistance: silicon carbide has good chemical stability for a variety of acid and alkali media, and is suitable for sintering operations in a variety of complex environments.

3. High thermal conductivity: Its high thermal conductivity contributes to rapid and uniform heating, improving sintering efficiency and reducing energy consumption.

Addition and performance optimization of auxiliary materials

1. The role of the binder: by adding an appropriate amount of the binder, such as silicate, alumina, etc., can improve the agglomeration of silicon carbide powder, enhance the plasticity of the material, and facilitate molding processing.

2. The introduction of plasticizers: Plasticizers (such as polyvinyl alcohol, paraffin, etc.) can effectively reduce the viscosity of the material, improve the compactness and uniformity of the billet, which is conducive to the subsequent sintering process.

3. The addition of reinforcing phase: by adding reinforcing phases such as carbon fiber, graphite or silicon nitride, the mechanical strength and thermal shock resistance of the crucible can be significantly improved, and its stability at extreme temperatures can be enhanced.

Effect of manufacturing process on performance

Process parameters such as mixing uniformity, forming pressure, sintering temperature and holding time have important effects on the final performance of sic crucible. Reasonable process design can give full play to the potential of materials and realize the optimization of performance.

In summary, the performance optimization of sic crucible is a comprehensive process involving material composition, auxiliary material selection and manufacturing process control. By precisely regulating the ratio of silicon carbide core material and auxiliary material, combined with scientific manufacturing process, the hardness, wear resistance, corrosion resistance and mechanical strength of the crucible can be significantly improved, while optimizing its thermal conductivity to meet the diverse needs of the field of high temperature sintering. In the future, with the in-depth development of material science and the continuous innovation of preparation technology, the performance of silicon carbide crucible will be further improved, and the application field will continue to expand, contributing to the technological progress and sustainable development of related industries.