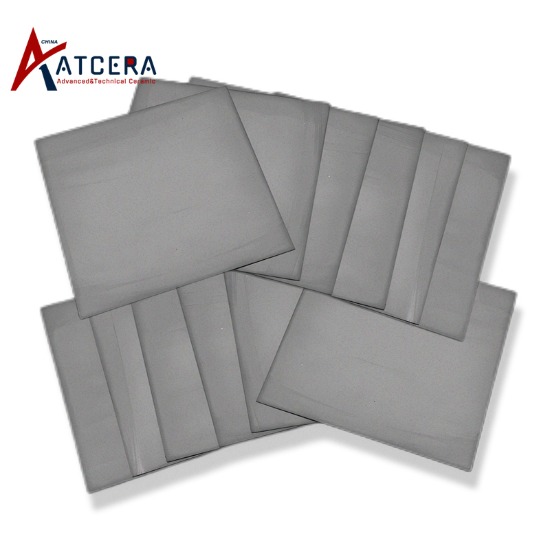

Silicon nitride substrate metallization technology is an advanced technology, its core technology is to accurately achieve the solid bonding of metal layers on the surface of silicon nitride ceramic substrate. Through this technology, the ceramic substrate is endowed with metal properties such as electrical and thermal conductivity, which greatly expands its application range.

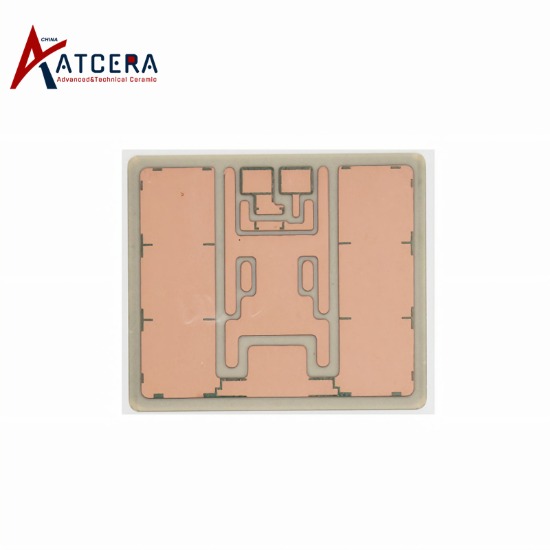

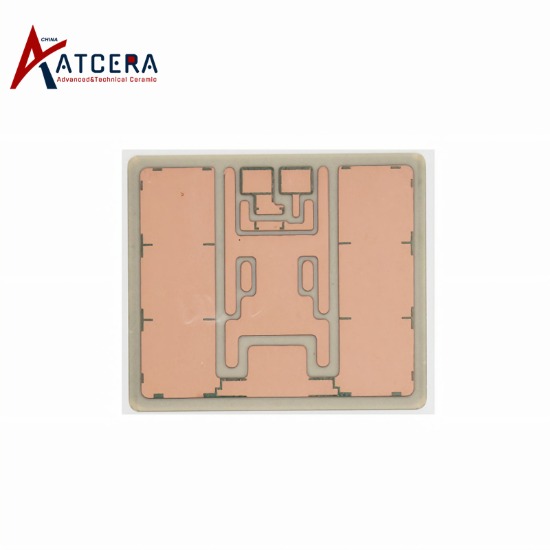

In the field of electronic packaging, the application of silicon nitride ceramic substrate metallization technology significantly improves the reliability of packaging structures and reduces the risk of failure caused by thermal stress during the operation of electronic equipment. In the field of integrated circuits, the technology effectively improves the connection performance between the chip and the substrate, and provides strong support for improving the performance and stability of integrated circuits. In the field of microwave devices, the silicon nitride ceramic substrate metallization technology guarantees the reliable operation of microwave devices at high power and high frequency with its excellent thermal conductivity and stability.

Technical method for metallizing silicon nitride ceramic substrate

The co-firing method is a method of embedding passive components such as signal lines and microwires into the substrate by using thick film technology. This method is mainly divided into high temperature co-firing and low temperature co-firing two kinds, the process flow is basically the same, but the sintering temperature is different. The advantage of the co-firing method is that it can meet many requirements of integrated circuits, but there may be some problems such as inaccurate graph alignment in the laminating process.

Thin film method is a method to combine the film material and the ceramic surface by vacuum coating methods such as vacuum evaporation, ion plating, sputtering coating. In the metallization process, it is necessary to ensure that the thermal expansion coefficient of the metal film and the ceramic substrate is consistent to improve the adhesion. The advantages of thin film method are homogeneous metal layer and high bonding strength.

Key factors in the metallization process of silicon nitride ceramic substrate

In the metallization process, the precise control of temperature is undoubtedly a crucial part. The bonding quality and properties of metal layer and ceramic substrate are directly affected by temperature fluctuation. Excessive temperature may lead to excessive melting of metal layer, reduce its structural stability, and even lead to thermal damage of ceramic substrate. However, too low temperature may lead to insufficient bonding between the metal layer and the ceramic substrate, which will affect its overall performance.

The choice of solder also has a decisive influence on the quality of metallization. The composition of the solder should be rich in active elements to ensure a solid bond with the ceramic substrate during the sintering process. The wettability of solder is also an important index to evaluate its performance. Good wettability helps solder form a uniform distribution between the metal layer and the ceramic substrate, thereby improving the effect of metalization. In the metallization process of silicon nitride ceramic substrate, the commonly used metals include copper, silver and so on. These metals need to have good electrical conductivity, thermal conductivity and corrosion resistance to ensure that the metallized substrate has good performance.

Pressure control in the metallization process is also a factor that cannot be ignored. In the welding process, the appropriate pressure contributes to the tight bond between the metal layer and the ceramic substrate, and improves the bond strength. However, excessive pressure can lead to fracture or deformation of the ceramic substrate, so precise control of the welding pressure is required.

With the rapid development of electronic technology, the metallization technology of silicon nitride ceramic substrate is also improving. At present, the technology has been able to achieve high metallization quality, making the ceramic substrate maintain its original excellent performance with good electrical and thermal conductivity of the metal. In the future, with the continuous deepening of research and continuous innovation of technology, silicon nitride ceramic substrate metallization technology will play a more critical role in the manufacturing of electronic equipment, and make greater contributions to improving the performance, stability and reliability of equipment.